Crane Wheel

Overhead crane wheels are the most important parts in traveling unit and also are the most vulnerable parts due to the strong impact and wear between wheel and rail. Flange wear, flange breakage and fatigue pitting are the frequently encountered problems. When the overhead crane wheels are broken, the repair and replacement are complex and very time-consuming. To ensure the high quality of the crane wheels assembly, every step in design, material, heat treatment and processing technology is properly and precisely executed in DGCRANE.

- Material: 4140/SCM440 /42CrMo, ssw-Q1R/65#steel, 65Mn,50SiMn,QT800, ZG35SiMn, SSW-Q1

- Rated Loading Capacity: 1~160 ton

- Diameter: Φ250, Φ350, Φ400, Φ500, Φ600, Φ700, Φ800, Φ 1000, Φ 1200 or as your require

- Technology: Casting or forging

- Quenching Depth: No less than 20mm

- Heat Treatment: Quenching and tempering

- Work environment temperature: -25℃~+40℃, relative humidity ≤85%

- Reference Price Range: $750-4500/set

Overview

According to the different forming process, there are two typical types: casting wheels and forged wheels. Due to different material, heat treatment, we just can’t make a brief contrast between them. Because of different design of crane, the overhead crane wheels are often very different. So the custom designed wheel and OEM is accepted, in fact, is the most common case in export. Meanwhile, our engineers are always ready to make recommendations when these wheel need to be integrated into complete wheel assemblies or in a very specific application.

Now, here comes a brief introduction of our production capacity.

- Advanced design and production capability in crane wheel

- Strong production capability, powerful rough and finish machining capabilities diameters of 150mm to 900mm (6” to 36”) available both in casting and forged

- Different kinds of heat treatment capabilities quenching and tempering, intermediate and high frequency surface quenching

- Material – or according to customer requirments

FLANGED CRANE WHEELS are mainly used in all kinds of lift machines, such as single girder overhead crane, double girder overhead crane, gantry crane, and port crane etc. FLANGED CRANE WHEELS are various, like single rim wheel, double rim wheel, non-rim wheel, and other nonstandard wheels. The material of wheels includes 42CrMo4, AISI4140, 41Cr4, A504, SSW-Q1R, 65Mn, 1045, 1055, 1060, 1070, and ductile iron 400, 500,600,700 etc. DGcrane Wheel apply different crafts of different material, precisely control the quench and temper temperature, so that the wheel can reach the metallographic structure and mechanical property.

There’re three heat treatment methods according to different requirements:

- The first is through hardening & tempering, wheel surface hardness HB300-380, mainly used for standard crane products.

- The second is surface medium frequency quenching & termpering, wheel surface hardness HB300-380 or HRC50-56, mainly used for products which with low wheel center hardness & high wheel surface surhardness requirements and unsuited whole heat treatment.

- The last one is through hardening & tempering, wheel surface hardness up to HRC50-56, wheel surface hardness decay with depth due to the differences of raw materials, forged alloy steel wheels’ the depth of hardening layer up to 15mm and thus low hardness attenuation, mainly used for port crane, bucket-wheel excavator, bucket-wheel stacker reclaimer and other heavy load products.

FLANGED CRANE WHEELS are replaced because of flange wear, flange breakage, and mechanical overloads characterized by pitting and spalling. Each of these in-service factors must be carefully considered before the combination of wheel design, material selection, hardness pattern and heat-treating technology is selected.

Applications

- Eot Cranes

- Gantry and portal cranes

- Transfer cars

- Contact us. The advantages of our products will surprize you.

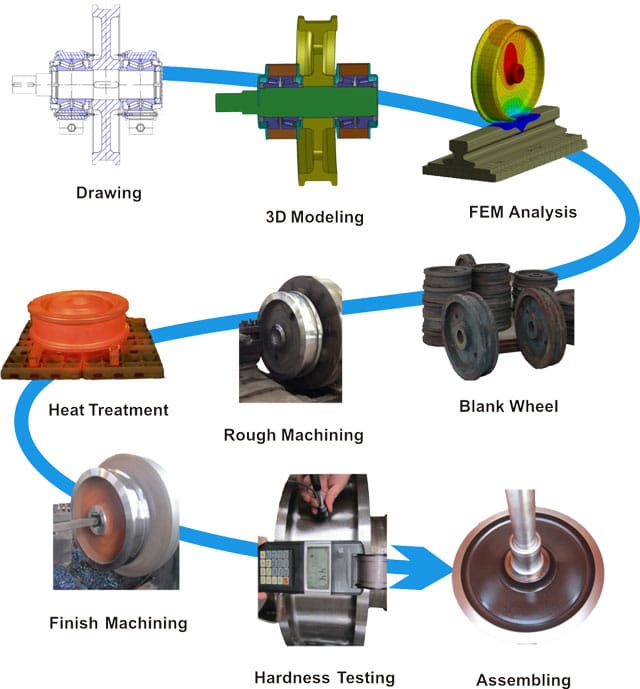

Crane Wheel Processing Chart

A Standard Crane Wheels Will Be Produced in 20 Days.

On-Site Installation or Remote Instruction Is Available

Trust building is really hard, but with 10+ years of sales experience and 3000+ projects we've done, both end-users and agents have gained and benefited from our cooperation. By the way, Independent sales rep recruiting: Generous commission / Risk free.