Workstation Overhead Cranes

Workstation overhead crane with a lifting capacity of 0.125t-2t, and a wide range of applications. The biggest advantage of our company's Workstation overhead crane is that it can be easily expanded and adapted to new requirements at any time, and it can develop together with your business.

- Capacity: Up to 2ton

- Span length: Up to 9meters

- Lifting height: Up to 1.5meters

- Work duty: M4~M7

- Raged voltage: 220V~690V, 50-60Hz, 3ph AC

- Work environment temperature: -20℃~+60℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

- Reference Price Range:$900-5000/set

Overview

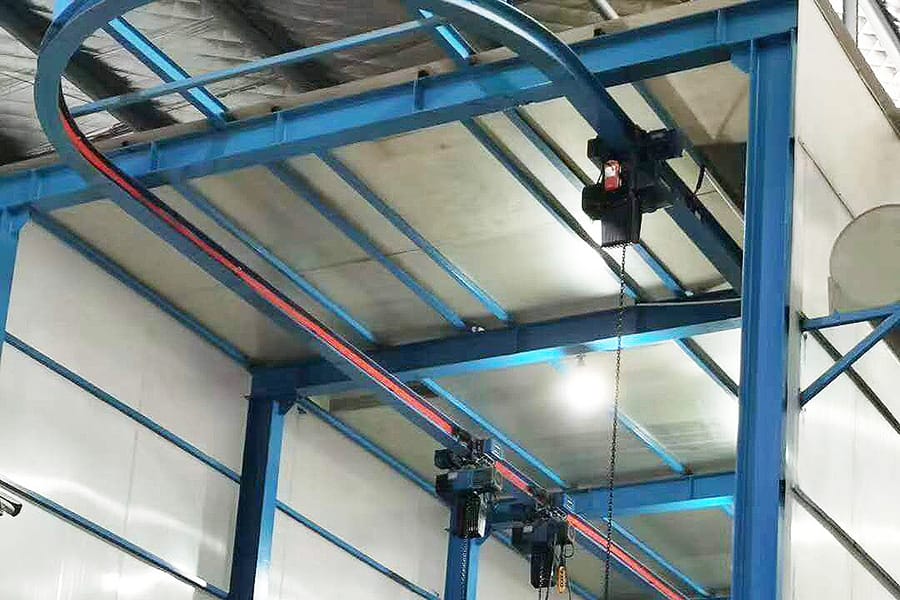

Workstation overhead crane include various types of lifting equipment such as Workstation Overhead Crane-LD single beam, Workstation Overhead Crane-LS double beam, Workstation Overhead Crane-LM stacker, etc. Due to the standardized and modular component design, various types of cranes can be matched in a short time according to the different needs of users and specific handling routes. Workstation Overhead Crane cranes will be used in more and more occasions and have a wider prospect.

Advantages

- Reliability and stability

- Easy to install

- Compact structure

- Light weight

- Wide application

- Good space utilization

Options and Components

It can realize the horizontal movement of the electric hoist. It is made of high-strength steel Q235. The surface of the Workstation Overhead Crane track is shot blasted first, then subjected to anti-corrosion treatment, and then sprayed with anti-corrosion paint after treatment.

Composed of Q235 thick steel plate, it can run freely on the rail girder, and can also realize the left and right movement of the electric hoist.

Electric hoist is to be used on Workstation Overhead Crane light crane system, each electric hoist will perform dynamic and static load test, rise and drop pressure tests. The baking paint process is adopted to enhance the adhesion of the paint film and improve the appearance quality. Assembly line ensures product quality.

Generally can be installed on the lower edge of I-beam or H-beam, with a certain self-locking function, easy and reliable installation.

Turnouts, cross turntables, lifting sections, etc., which are combined with standard rails to form a single-track material conveying network to meet the requirements of various forms of process layout

Our standard power supply is three phase, 380V (±10%, the lower limit of peak current is -15%), 50Hz. According to customer requirements, the power supply can be designed as a three-phase electrical control system under 690V and frequency 50-60HZ.

Pendant panel, Remote control, Cabin control. The crane can also be equipped with two sets of operating devices, namely: ground + remote control or driver’s cab + remote control. However, due to safety issues, the two operating modes can only be switched and cannot be used at the same time. The control circuit voltage is generally AC 36V safe voltage.

Types of Cranes for Different Working Conditions

Workstation Overhead Crane Telescopic Beam Crane

- This product can bypass obstacles or move objects to difficult-to-access support columns (such as columns, etc.). It can increase the auxiliary working area, so that special objects or equipment can make full use of their use space.

- It can be assembled with standard Workstation Overhead Crane components and Workstation Overhead Crane special components according to the overhang and telescopic dimensions required by the actual process of the customer.

Workstation Overhead Crane Monorail Suspension Crane

- This type is suitable for linear transportation of materials. It can connect the loading station and the unloading station.

- It can be powered by the whole line, and each running trolley can be driven by itself, which can realize the two-way transportation of materials.

- It can realize any direction of different orbits such as manual control of linear orbits, semi-automatic and fully automatic control of circular orbits, etc.

Workstation Overhead Crane-LS (Workstation Overhead Crane Double Beam Suspension Crane)

- Double beam Workstation Overhead Crane track has heavy load capacity and is widely used for lifting heavy materials.

- The position of the hoist is between the two main beam sections to ensure the maximum utilization rate of the lift control.

- It is used for plane material transportation, suitable for workshops, warehouses, etc., commonly used in the lifting of larger spans and heavier materials

Workstation Overhead Crane-LD (Workstation Overhead Crane Single Beam Suspension Crane)

- Due to its special flexibility and freedom, it can walk on the traveling track or run on the variable-span track.

- It can be used only with bolt connection, which can save the space and area of the factory, thereby reducing energy consumption and improving enterprise efficiency. It can be operated manually, as well as automatic and semi-automatic operation.

- The connection between the crane beam box traveling mechanism uses universal ball joints, so that the crane does not appear to be clamped, and can pass through the wedge-shaped section and protruding part of the track without hindrance.

On-Site Installation or Remote Instruction Is Available

Trust building is really hard, but with 10+ years of sales experience and 3000+ projects we've done, both end-users and agents have gained and benefited from our cooperation. By the way, Independent sales rep recruiting: Generous commission / Risk free.