FEM Standard Gantry Cranes

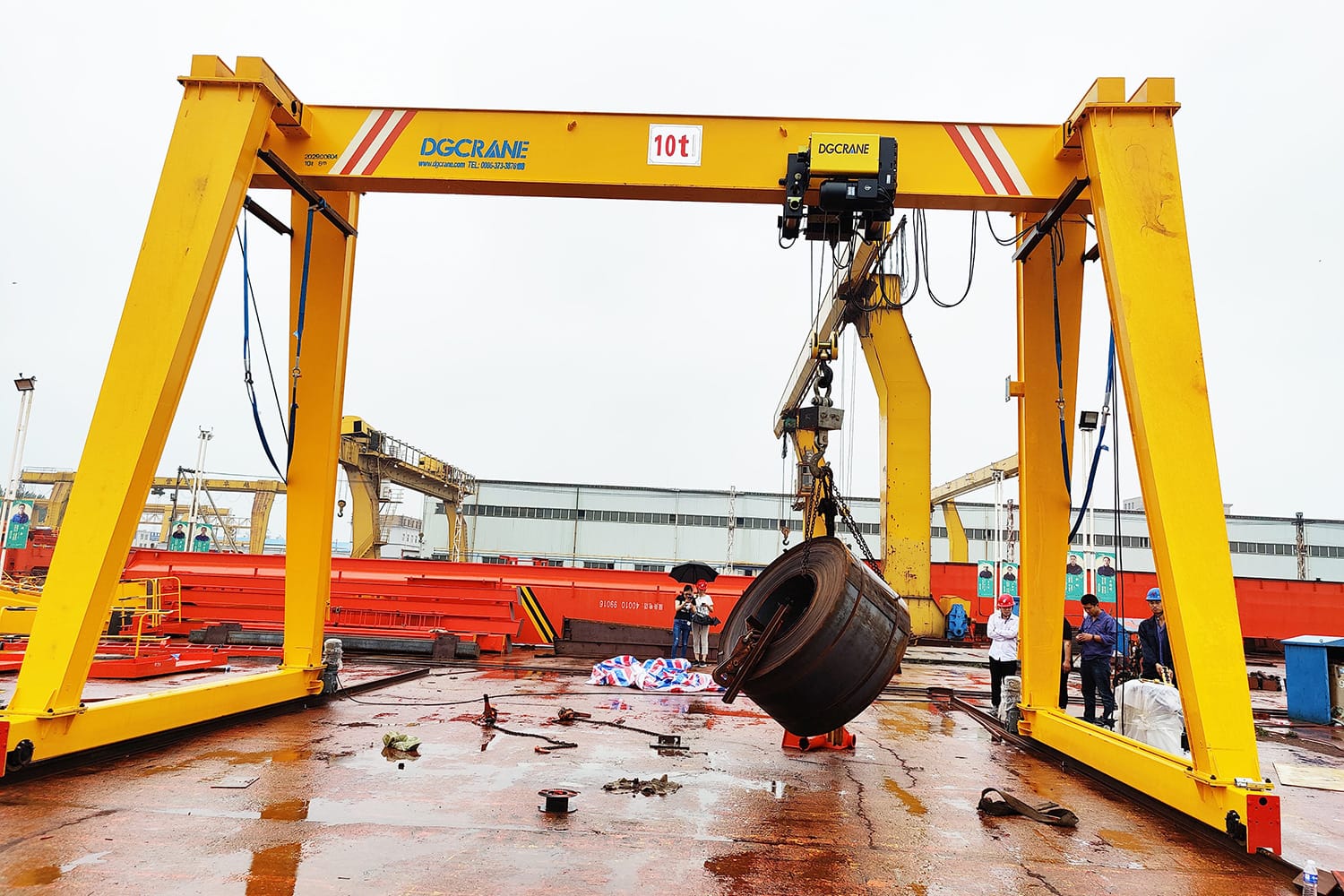

European type gantry crane adopts European design standards and manufacturing technology, it meets the advanced level of international similar products such as low height, light weight, small wheel pressure, flexible direct drive, stepless speed change, and maintenance-free.

- Capacity: 1-320ton

- Span: 4-35m

- Lifting height: customized according to the site conditions

- Duty group: A5 A6

- Raged voltage: 220V~690V, 50-60Hz, 3ph AC

- Work environment temperature: -25℃~+40℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

Overview

European type gantry crane adopts European design standards and manufacturing technology, it meets the advanced level of international similar products such as low height, light weight, small wheel pressure, flexible direct drive, stepless speed change, and maintenance-free.

The crane moves longitudinally on the rails through the ground carriages, and the trolley moves laterally on the crane gantry structures, and the hook lifts to realize the movement, loading and unloading and stacking of materials. There is a set of independent lifting mechanism on the trolley. A rain cover is provided on the trolley assembly.

The European type gantry crane is composed of main parts such as steel structures, trolley, crane long traveling mechanism, electric mechanism. In addition to rail clamps, the crane can also be equipped with anchoring devices, anchor cable devices, wind speed/wind direction meters and other wind-proof or braking devices.

Advantages

- FEM/DIN Standards

- Light weight design

- Modular design

- Advanced Manufacturing technology

- High security & High reliability

- Low-energy & maintenance-free

Components

Q235 carbon structural steel with seamless once forming technology more strong and elegant.

The main beam adopts welded box or truss type.

In order to facilitate inspection and maintenance, pedestrian passages and railings are provided on the main beam.

It adopts a welded box or truss structure, and the legs are composed of upper flanges, lower flanges, and supports welded by steel plates or section steels. The upper flange is large and the lower flange is small, making the legs a variable cross-section structure with a large upper and a small lower flange, which can effectively carry vertical and horizontal loads.

Strong box type with crane long traveling gear motors installed on, buffers also installed on the ground girders

For single girder gantry crane, the lifting mechanism is European type wire rope hoist; for double girder gantry crane, the lifting mechanism is QD trolley.

Both types are with compact design, high protection class, light dead weight and great working performance.

For gantry crane running outside the workshop, power supply by cable reel and cable wire, for gantry crane running inside the workshop, we will choose the most reasonable ways for customer.

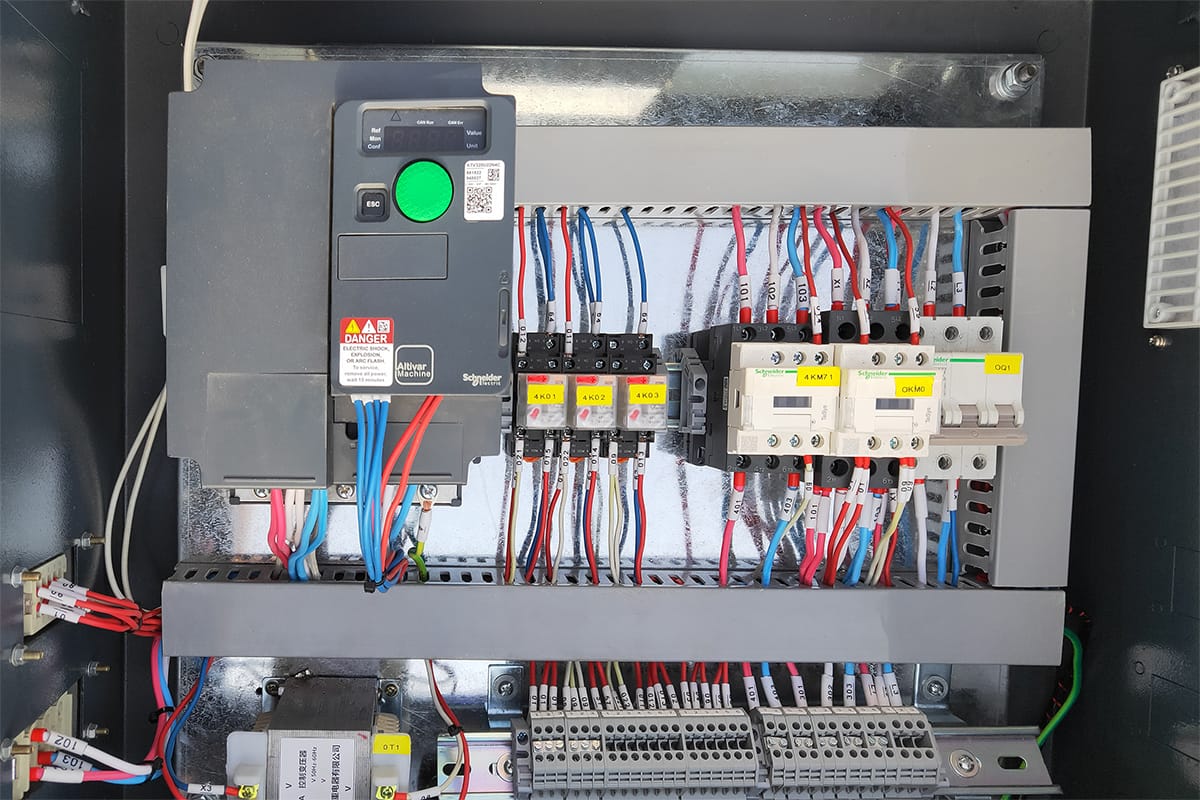

Main electric components uses Schneider, Siemens, ABB and other international well-known brands, electric cabinet with not less than IP54 protection grade

Safe and reliable ladders, platforms and walkways are provided where operations, inspections, and maintenance are required, and there is sufficient working space. Railings are set on the platform walkway, the height of which is 1050mm. Consider anti-skid safety measures for platform walkways to make sure safety.

The hook head is forged from special steel for the hook, and is connected to the shell through the hook beam with a thrust bearing to ensure that the hook can run freely in the horizontal 360°. The hook is equipped with a safety buckle that prevents slippage.

The hoisting mechanism steel wire rope is imported from Italy that meets the current international standards. The breaking force of the steel wire rope is not less than 2160N/mm2, and the safety factor is not less than 5. The steel wire rope is galvanized steel wire rope without maintenance or anti-rust oil. Durable, the external steel wire rope cross-section is a special-shaped cross-section, which is beneficial to reduce wire wear, extend the service life of the wire rope, and have better flexibility.

Types of Cranes for Different Working Conditions

On-Site Installation or Remote Instruction Is Available

Trust building is really hard, but with 10+ years of sales experience and 3000+ projects we've done, both end-users and agents have gained and benefited from our cooperation. By the way, Independent sales rep recruiting: Generous commission / Risk free.