Crane Trolley

For double girder bridge crane and gantry crane,the hoisting mechanism and trolley traversing mechanism generally have the following type:

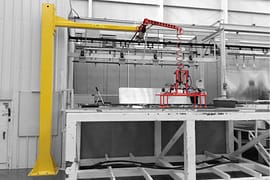

LH hoist trolley: Lifting capacity: 5t-32t; Duty group M3; Using CD, MD, HC wire rope electric hoist;

Integrated hoist trolley: Lifting capacity: 5t-32t; Duty group M3; Using CD, MD, HC wire rope electric hoist; (It is suitable for small space in the upper part of the plant.)

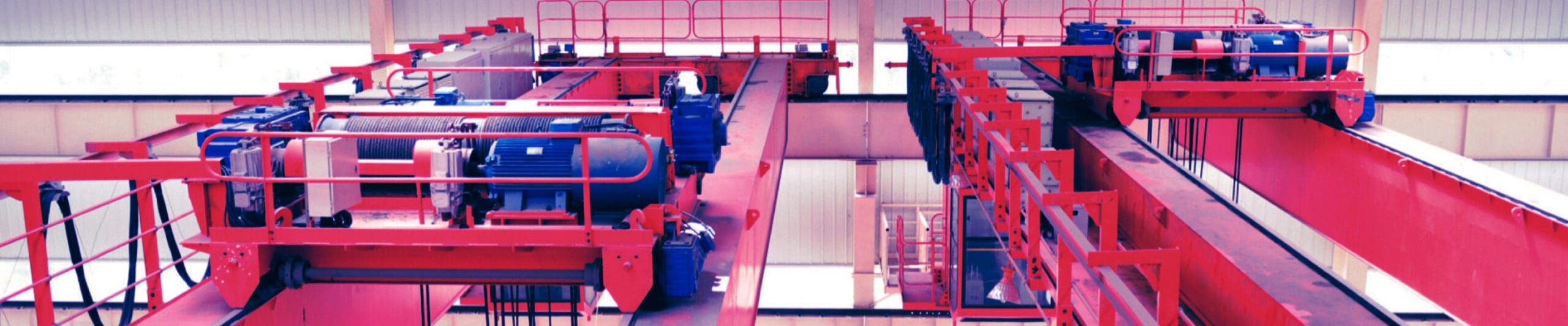

QD hoisting trolley: Lifting capacity: 5t-800t; Duty group can reach M8; This type of trolley is a medium-heavy lifting equipment.

Overview

The QD trolley is mainly composed of the lifting mechanism, trolley frame and traveling mechanism. It can be used for QD double girder overhead crane and MG double girder gantry crane, and also can be installed on the stationary chassis, and used as hoisting winch to lift and transport the materials up and down. The trolley rail gauge can also be designed and produced according to the actual working situation.

Components

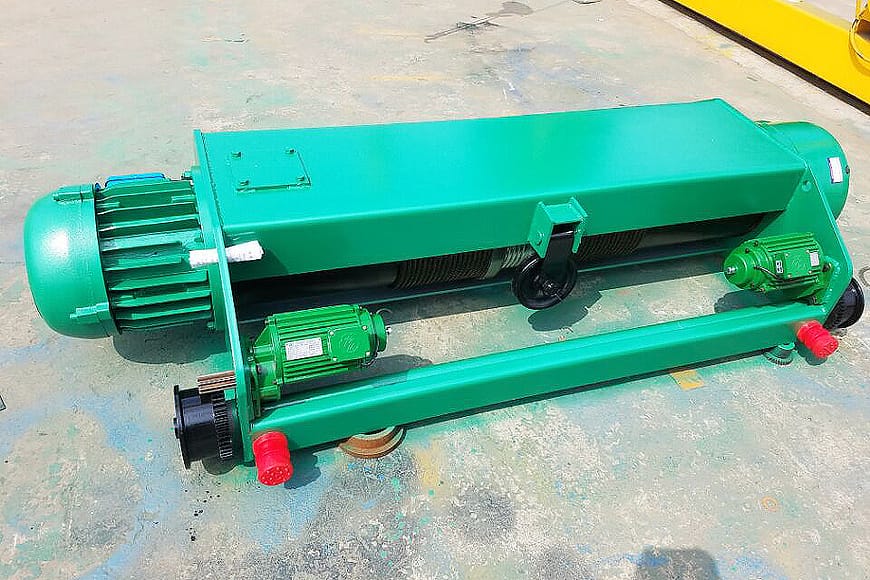

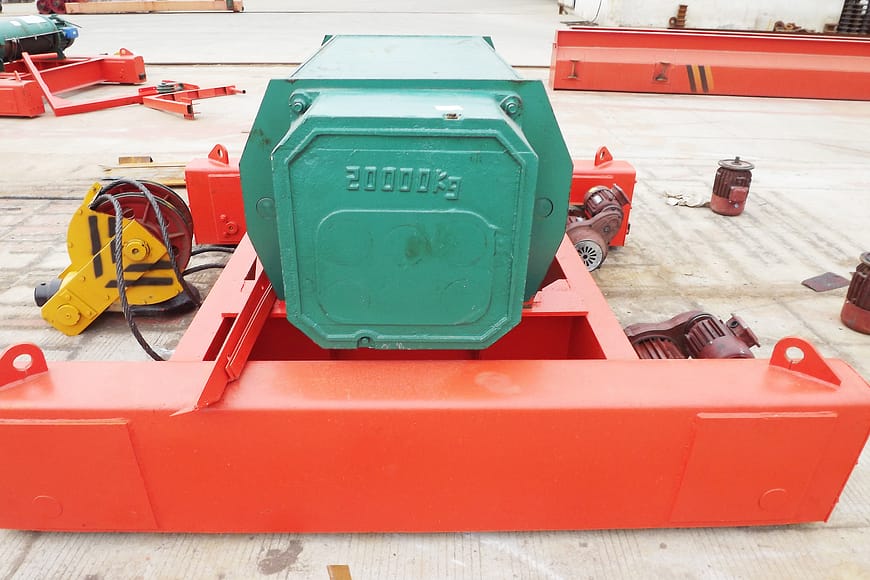

It is mainly composed of drum, hoisting motor, hoisting reducer, brake, steel wire rope and hook group (or grab, electromagnetic chuck), etc. It can have 2 lifting mechanism, one is main mechanism, another one is aux mechanism, they can be used independently or together.

It is a combined structure of plate welding, which has sufficient strength and rigidity to ensure that the trolley frame will not affect the normal operation of each mechanism after being loaded and deformed.

If used outdoor, it adopts a sealed rain cover which has daylighting measures.

It is composed of running motor, running reducer, wheel set, etc. It is equipped with safety devices such as stoppers, rail clearers, buffers, and operating limits.

It adopts the scheme of 1/2 active wheel and single motor driving the wheels. The forces on each wheel are balanced, the wheels run smoothly, no rail gnawing phenomenon occurs, and the installation, disassembly and maintenance of the wheel device and other parts are simple and convenient.

A Standard Lifting Trolley Will Be Produced in 15 Days.

Trolley frame production

Traversing mechanism assembly

Lifting mechanism assembly

Brush paint

Warehousing

Tips:

Lead time of cranes with different voltage may be 10-15 days longer as electrical components need to be customized by our supplier.On-Site Installation or Remote Instruction Is Available

Trust building is really hard, but with 10+ years of sales experience and 3000+ projects we've done, both end-users and agents have gained and benefited from our cooperation. By the way, Independent sales rep recruiting: Generous commission / Risk free.