Crane Electromagnetic Lifting Magnets: for Safe and Efficient Steel Handling

Crane electromagnetic lifting magnets are efficient tools for handling ferromagnetic materials like steel plates, cast iron, steel balls, pig iron, and machining chips. They work by passing current through a coil to generate a magnetic field, enabling quick and secure lifting while improving efficiency and safety.

How Electromagnetic Overhead Cranes Work: When paired with overhead cranes, the magnet is energized to lift metal loads and de-energized to release them, allowing smooth, precise material handling.

These magnets are widely used in steel mills, casting workshops, shipyards, heavy machinery manufacturing plants, and warehouses. Our products support non-standard customization to suit specific site requirements.

Power-Failure Magnetic Retention Function for Crane Electromagnetic Lifting Magnets:

- Function: Prevents the sudden dropping of suspended loads during a power outage, ensuring the safety of personnel and equipment.

- Implementation: Equipped with a power-failure magnetic retention device that automatically switches to a backup power supply when the main power is lost.

- Backup Power Supply: Typically uses a battery pack that provides short-term continuous power to maintain magnetic force.

- Control System: Features automatic detection and switching, requiring no manual intervention.

- Automatic Charging: The battery pack is automatically charged and maintained to ensure it is always ready for emergency use.

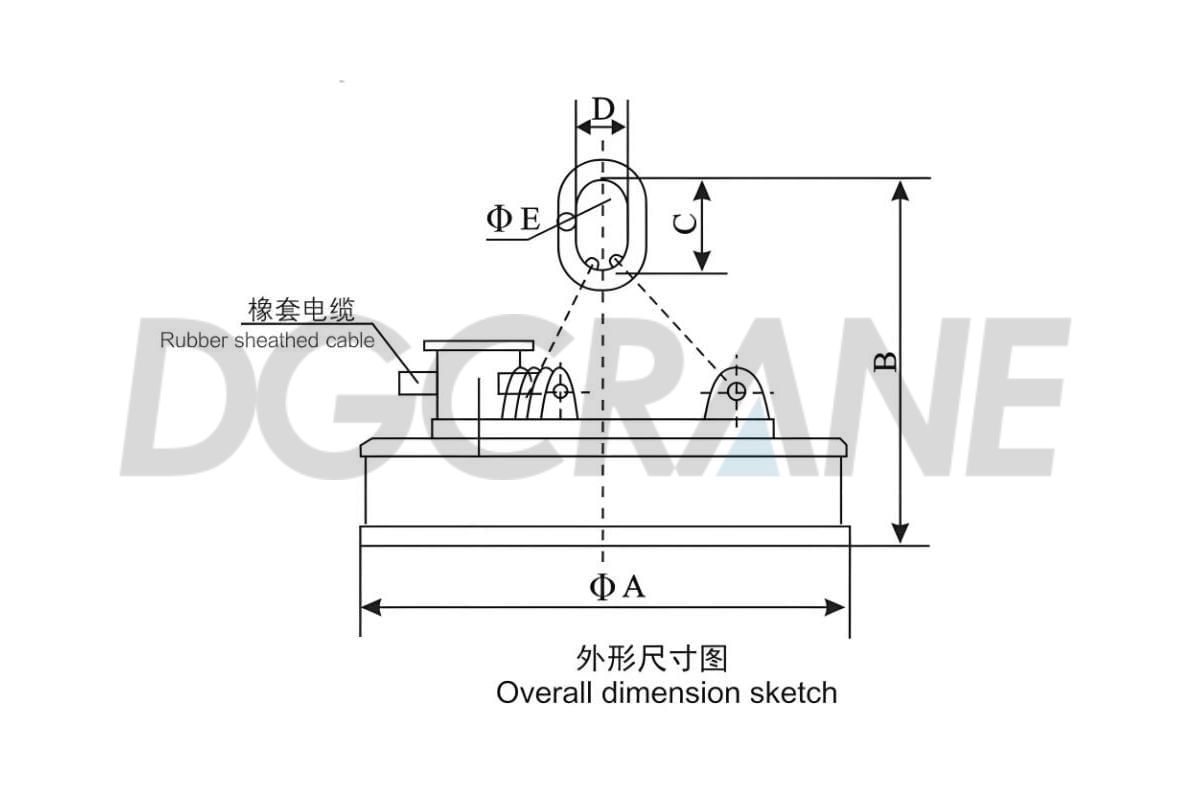

Round Electromagnetic Lifting Magnets

This series is used for sucking and lifting cast iron ingot, steel balls, pig iron blocks, machine plus chips; foundry’s all kinds of miscellaneous iron, blast furnace material, cutting head; baling scrap steel, and so on.

Parameters

For detailed product information, please refer to the PDF.

Application

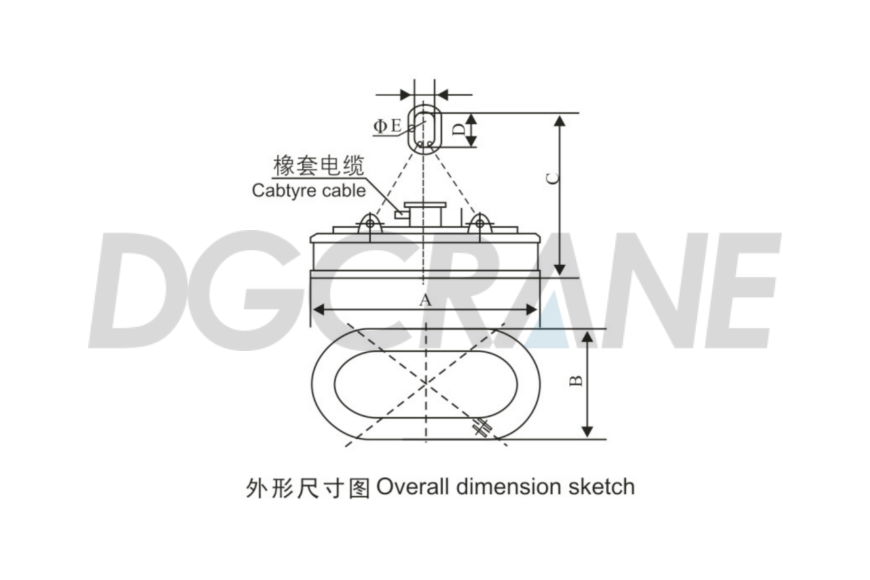

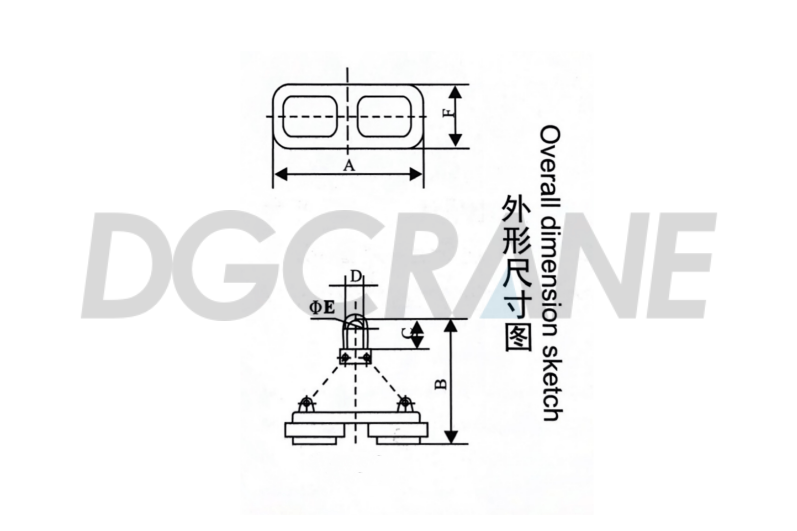

Oval Electromagnetic Lifting Magnets

It can load & unload steel scraps efficiently in a narrow, trunk-shaped container and is called oval oval-shaped electromagnet owing to its special half-round structure. As chute dimensions in various steel companies are different, the following sample is just for your reference. And we can make the specific one as per your requirement.

Parameters

For detailed product information, please refer to the PDF.

Application

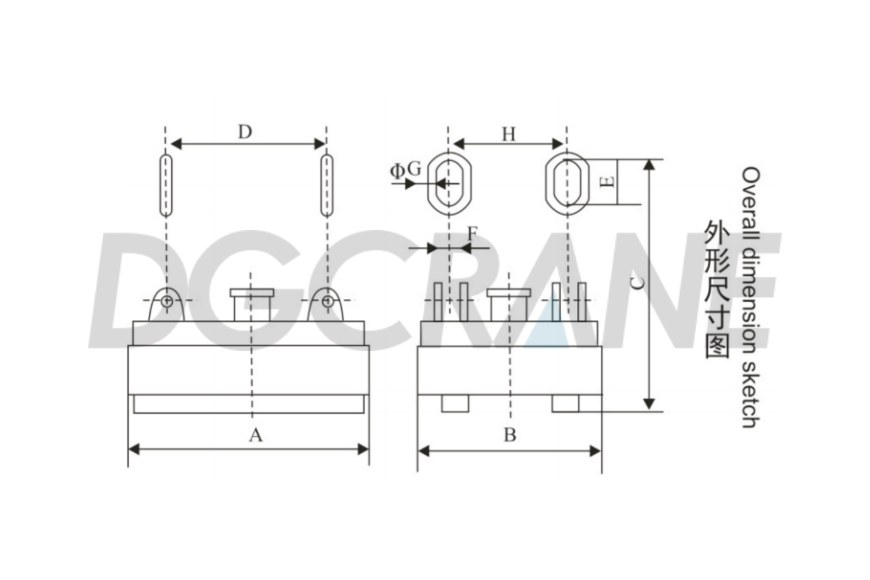

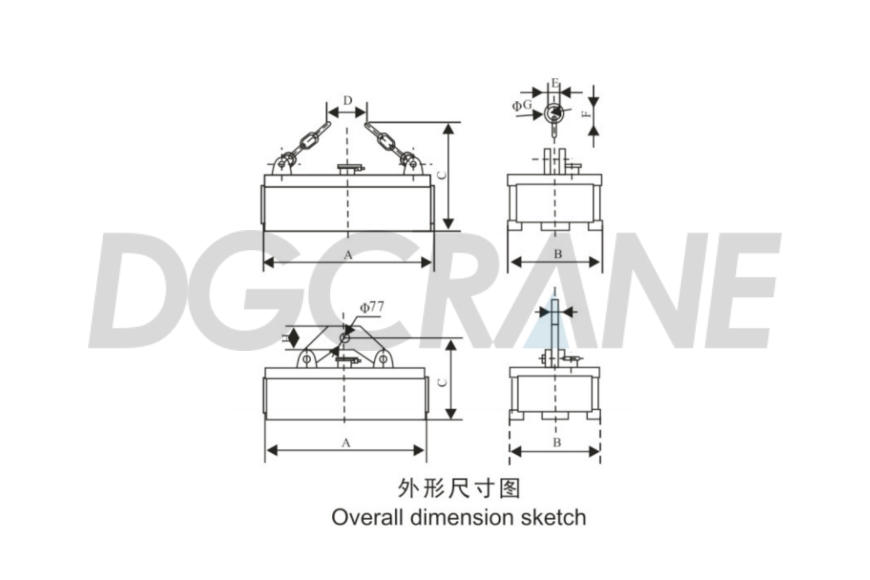

Rectangular Electromagnetic Lifting Magnets

This series of products for the design of a strong magnetic circuit can penetrate the multi-layer air gap, applicable to the lifting of the bundling bar.

This series of products are more than the use of a combination of suckers.

Parameters

For detailed product information, please refer to the PDF.

Application

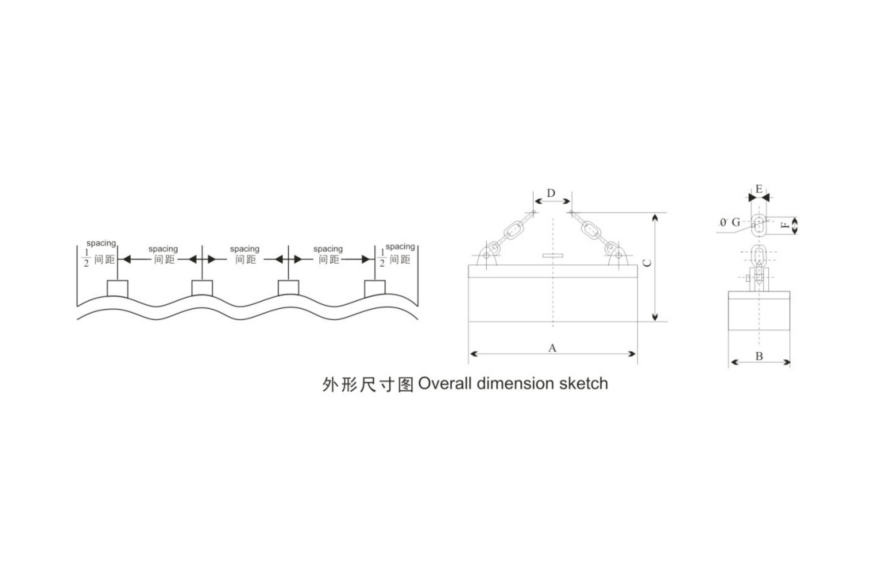

Strip-shaped Electromagnetic Lifting Magnets

This series is specially designed for lifting and transporting medium-thick steel plates. The whole operation is safe, exact, and quick. When transporting some long plates, they easily distort. So we advise a combination of multiple units to be used.

Parameters

For detailed product information, please refer to the PDF.

Application

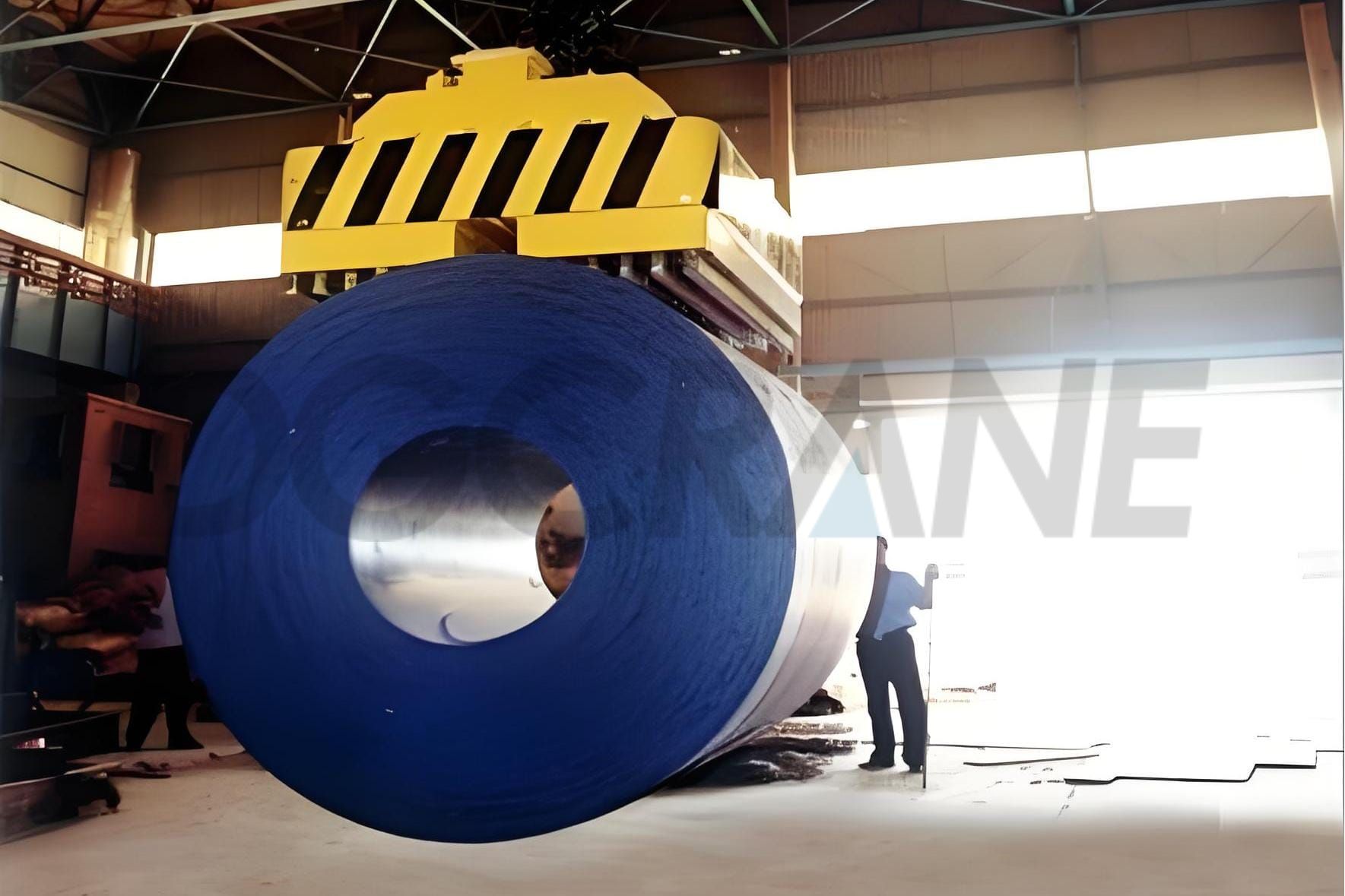

Rectangular Electromagnetic Lifting Magnets Assembly

This series is used for coiled steel and has three kinds: vertical type, horizontal type, and general type, which can lift material both vertically and horizontally. High-temperature type can be used in an annealing process and can lift material vertically or horizontally in the high-temperature range from 100°C to 600°C.

Parameters

For detailed product information, please refer to the PDF.

Application

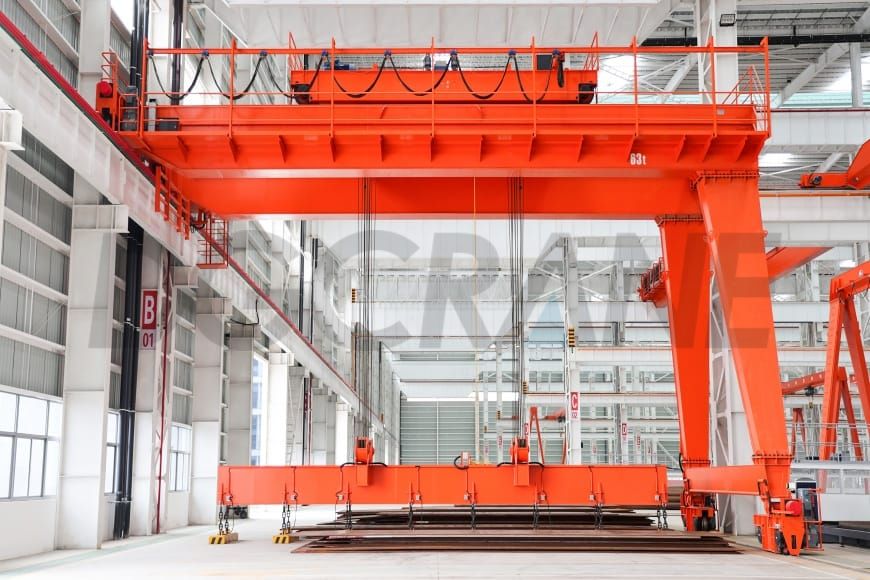

Beam-mounted Electromagnetic Lifting Magnets

The most widely used series, whose shape is rectangular especially suitable for lifting and transporting billet, steel ingot, bloom, etc., and round, profiled steel as well. Different magnetic circuits are designed for different steels.

Parameters

For detailed product information, please refer to the PDF.

Application

SELECTION CONSIDERATIONS

Crane Electromagnetic Lifting Magnets can be flexibly paired with various types of lifting equipment according to operational needs, including overhead cranes, gantry cranes, and jib cranes. This adaptability allows for efficient handling of magnetic materials in diverse working environments such as warehouses, steel mills, ports, and scrap yards. By selecting the appropriate crane configuration, users can achieve optimal lifting performance and improve overall workflow safety and efficiency.

- The main basis for the selection of the electromagnetic chuck is the material being absorbed.

- Suction waste steel is related to the accumulation of loose material, block degree, material level, working frequency temperature data, etc.

- When transporting the finished goods, it relates to the size of the material, the material quality, the quantity of the material, the working frequency, and the temperature data.

- When the temperature of the absorbing material is lower than 100 DEG C, the suction disc is selected. When the temperature is over 100 DEG C, the high temperature-resistant sucker is selected. Please specify more than 600 DEG C.

- Power throughout more than 60%, the use of high-frequency sucker.

- The water-absorbing material, the diving type sucker (diving depth less than 100m). Because of the diving type sucker and the normal temperature type suction cup phase, the user is pleased when ordering.

- Equipment supporting electrical appliances: single suction cups when used, according to the energy consumption of power (current) to select the rectifier control equipment and auxiliary equipment; multiple suction cups when combined, according to the combined use of the number of energy consumption (current) selection.

- According to the degree of difficulty of the material being transported, the actual situation of the selection of appropriate electromagnetic chuck, but also to consider the nature of each batch of material and chemical properties of the change, the season, the impact of suction on the suction when the wet.