Container Gantry Cranes: RTG & RMG Solutions for Ports and Terminals

Container gantry cranes are critical equipment widely used in ports, container yards, and intermodal terminals for the efficient handling, stacking, and transfer of standard shipping containers. Their main function is to move containers between trucks, rail wagons, and storage stacks, significantly improving cargo throughput and yard productivity.

Container gantry cranes can be broadly divided into two main types based on their design and mobility: Rubber-Tired Gantry Cranes (RTG) and Rail-Mounted Gantry Cranes (RMG).

Rail Mounted Container Gantry Cranes

Rail mounted container gantry cranes are core equipment for modern container yards and logistics hubs. They are specifically designed for efficient handling of standard 20′-45′ containers and special containers.

This model features a fully electric drive system and automated positioning technology, covering container handling capacities from 30 to 100 tons.

It is suitable for railway freight yards, port terminals, and inland multimodal transport centers, enabling precise stacking and fast transfer of containers, thereby enhancing logistics efficiency and intelligent warehouse management.

Specifications

| Lifting Capacity under Spreader (t) | 35 | 41 | 70 |

| Wheel Base (m) | 10/16 | ||

| Span (m) | 30/35/40 | ||

| Lifting Height (m) | 12.5/15.3/18.3 | ||

| Number of Stacking Layers | Stacking 3 over 1 / Stacking 4 over 1 / Stacking 5 over 1 | ||

| Container Specification | 20',40',45' | 20',40',45' | Twin 20', 20', 40', 45' |

| Hoisting Speed (Loaded/Unloaded) (m/min) | 13/20 | 13/20 | 20/40 |

| Gantry Travel Speed (Loaded/Unloaded) (m/min) | 45 | 45 | 45 |

| Trolley Travel Speed (m/min) | 70 | 70 | 70 |

| Number of Wheels | 16/20 | 16/20 | 24 |

| Maximum Wheel Load (kN) | 250 | 280 | 300 |

| Power Supply | Three-phase AC | ||

Features

- The company specializes in rail mounted container gantry cranes with upper rotation (trolley rotation) and lower rotation (lifting gear rotation), including cantilever and non-cantilever types, as well as rail-mounted cranes for railway use.

- Standard features include a bidirectional flexible resistance anti-sway system; optional multifunctional variable-frequency anti-sway micro-movement system and electronic anti-sway system provide significant sway prevention, easy maintenance, and improved container sway resistance.

- Equipped with CMS intelligent service management system for real-time monitoring of equipment operating status.

- Uses vector variable frequency, energy feedback, and torque balance control technologies for energy saving, environmental protection, convenience, and high efficiency.

- Features automated fault detection and real-time data display technology, ensuring safety and reliability.

- Offers multiple operation modes—manual, semi-automatic, automatic, and remote control—with advanced technology and stable performance.

- Core technologies include automatic operation positioning, intelligent container-to-container stacking, intelligent trajectory control, and intelligent safety protection.

- Comprehensive safety measures such as high wind alarms and dynamic safety scanning are fully implemented.

Rail Mounted Container Gantry Crane Price

| Lifting Capacity (t) | Span (m) | Lifting Height (m) | Duty Class | Operation Mode | Price (USD) | Remarks |

|---|---|---|---|---|---|---|

| 40.5 | 32 | 12 | A6 | Remote Control | $294,300 | Full variable frequency, effective 7.5m on each cantilever |

| 40.5 | 32 | 12 | A6 | Remote Control | $284,400 | Non-variable frequency, effective 7.5m on each cantilever |

| 40.5 | 40 | 15.8 | A7 | Remote Control | $1,015,600 | Effective 12.5m on each cantilever |

| 25+25 | 32 | 14 | A6 | Remote Control | $160,200 |

Case Studies

Zhejiang Petrochemical – Automated Rail Mounted Container Gantry Cranes

As an intelligent and green yard operation system, this project includes six remotely controlled automated rail mounted container gantry cranes. Each crane features automatic positioning, real-time monitoring, and intelligent remote control systems, enabling 24/7 unmanned on-site operation and management. The entire project supports efficient automated operation.

- Each mechanism uses redundant detection and dual positioning systems to ensure precise positioning during remote operation.

- Each unit is equipped with 24 high-definition cameras for real-time monitoring of the crane rail, containers, trucks, and container yard, assisting remote control.

- The remote monitoring management system displays equipment status in real-time through animated simulation, improving operational efficiency.

- Equipped with scanning recognition, anti-sway, and automatic operation systems to enable one-click automatic operations from truck side to container yard side.

Automated Container Gantry Crane Project in a Certain Country

- This container gantry crane is rated A8 for heavy-duty operation and is made from special materials to withstand high-latitude, extreme cold environments, capable of normal container handling at temperatures as low as -40°C.

- It features high-frequency operation and ultra-high-speed performance, achieving three times the handling efficiency compared to standard container gantry cranes.

- Equipped with full variable frequency drive and energy feedback system, ACCS automation control system, and GPS high-precision positioning system, enabling automated container handling, crane status visualization, and integrated logistics information.

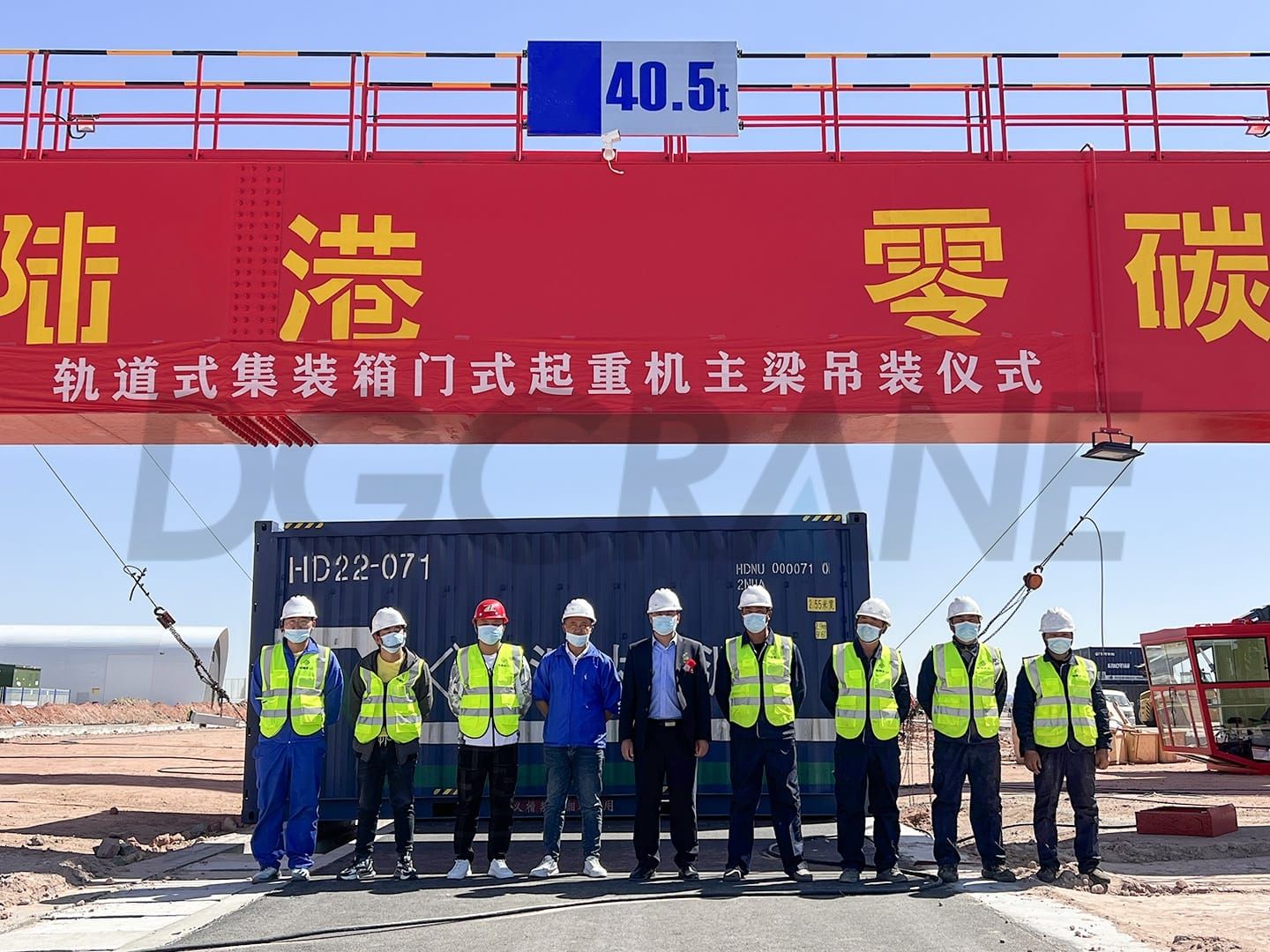

Ordos Wanli New Energy Smart Land Port

- The entire crane uses Schneider variable frequency drive and Siemens PLC control systems.

- Equipped with remote monitoring (RCMS) and operation functions.

- Features anti-sway system and truck anti-lift system.

- Achieves spreader zero-position monitoring and automatic spreader guidance through automatic container search and intelligent control.

- Ensures precise container handling positioning.

- Adapts to complex lifting positions.

- Effectively improves container loading and unloading efficiency.

- Meets Wanli Land Port's daily handling and lifting requirements.

Rubber Tyred Container Gantry Crane

Rubber-Tired Container Gantry Cranes (RTG) are suitable for handling and loading/unloading international standard containers at container yards or transit stations in ports, docks, and logistics centers. They are supported on pneumatic rubber tires and are commonly powered by diesel generators, but can also use cable reels, lithium batteries, or other power sources.

Specifications

| Lifting Capacity under Spreader (t) | 35 | 41 | 70 |

| Wheel Base (m) | 7 | 7 | 7.5 |

| Span (m) | 23.47/26 | 23.47/26 | 23.47/26 |

| Lifting Height (m) | 15.5/18.5 | 15.5/18.5 | 15.5/18.5 |

| Number of Stacking Layers | 4/5 | 4/5 | 4/5 |

| Container Specification | 20',40',45' | 20',40',45' | 20',40',45' |

| Hoisting Speed (Loaded/Unloaded) (m/min) | 20/40 | 25/50 | 25/50 |

| Gantry Travel Speed (Loaded/Unloaded) (m/min) | 30/130 | 30/130 | 30/130 |

| Trolley Travel Speed (m/min) | 70 | 70 | 70 |

| Number of Wheels | 8 | 8/16 | 16 |

| Maximum Wheel Load (kN) | 300 | 320/180 | 200 |

| Power Supply | Diesel generator set or three-phase AC | ||

Features

- The company offers various power configurations (diesel generator sets, mains power, small diesel generator sets + lithium batteries) for energy saving and environmental protection.

- Standard dual-direction flexible resistance anti-sway system; optional multifunctional variable-frequency anti-sway micro-movement system and electronic anti-sway system provide significant sway prevention, easy maintenance, and improved container sway resistance.

- CMS intelligent service management system for real-time monitoring of equipment operating status.

- Vector variable frequency drive, energy feedback (when powered by mains or lithium battery), and torque balance control technologies ensure energy efficiency, convenience, and high performance.

- Automated fault detection and real-time data display technology guarantee safety and reliability.

- Unique trolley correction and fine-tuning technology with personalized steering, lifting, and anti-tilt design for the trolley.

- Multiple operation modes available—manual, semi-automatic, automatic, and remote control—with advanced technology and stable performance.

- Core technologies include automatic operation positioning, intelligent container-to-container stacking, intelligent trajectory control, and intelligent safety protection.

- Comprehensive safety measures including high wind alarms and dynamic safety scanning are fully implemented.

Case Studies

RMG vs. RTG: Comparison

In container yards and port handling operations, Rail Mounted Gantry cranes (RMG) and Rubber Tyred Gantry cranes (RTG) are the two most common types. Each has its own advantages and is suited to different operational scenarios and requirements.

| Aspect | RMG (Rail Mounted Container Gantry Crane) | RTG (Rubber Tyred Container Gantry Crane) |

| Running mechanism | Runs on fixed rails | Equipped with rubber tires, moves freely in the yard |

| Application | Mainly used in railway container yards and large ports | Mainly used in container yards with flexible space and layout |

| Span and coverage | Can cover more container lanes or railway tracks | Flexible but limited span and coverage |

| Power source | Usually powered by electricity, more eco-friendly | Mainly diesel engine, but hybrid and electric types also exist |

| Automation | Easier to achieve automated and remote control | Automation is harder to implement |

| Cost | Higher initial investment, lower maintenance and operation cost | Lower initial investment, higher fuel and maintenance cost |

For more details, please refer to the original article from DGCRANE: RMG Rail Mounted VS RTG Rubber Tyred Container Gantry Cranes