Manual Portable Gantry Crane: Cost-effective & Flexible for Light Lifting

The manual portable gantry crane, also known as a manual mobile gantry crane, is a lightweight and mobile gantry crane that is suitable for small and medium-sized factories, workshops, or warehouses that require frequent movement and lifting of light goods. It features easy handling, simple operation, and safety and reliability, and can reduce labor intensity and improve work efficiency.

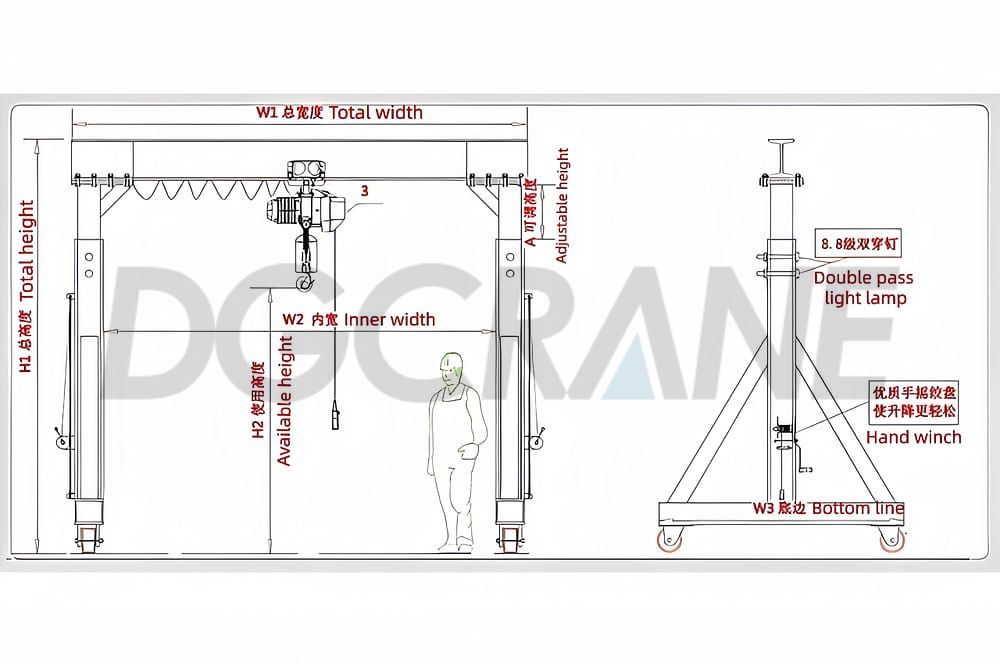

Components of Manual Portable Gantry Crane

- Bolted connection beam: The common material is Q235B/Q345B carbon steel. After welding, the overall structure is not easily deformed and has a strong load-bearing capacity.

- Square tubing uprights: Made of square tubing, ensuring good verticality and stability.

- Caster wheels: Available in materials such as nylon, polyurethane, and stainless steel, offering varying hardness and wear resistance.

- Chain hoist, made of high-quality alloy steel, with high strength and high safety factor (CD/MD hoist also available, with lifting speeds of normal speed and normal speed + slow speed, ensuring stable lifting of goods).

Technical Parameter

| Rated load | Width(mm) | Height(mm) | Available height(mm) | Adjustable height(mm) | Configuration and size description | ||

| W1 | W2 | W3 | H1 | H2 | A | ||

| 0.5T | 4000 | 3800 | 1500 | 2800-4000 | 2100-3300 | 1200 | Manual swivel casters with brakes; optional electric operation; adjustable height and width to meet specific needs. |

| 1T | 4000 | 3760 | 1500 | 2800-4000 | 2000-3200 | 1200 | |

| 2T | 4000 | 3700 | 1500 | 2800-4000 | 1850-3050 | 1200 | |

| 3T | 4000 | 3700 | 1500 | 2800-4000 | 1700-2900 | 1200 | |

| 5T | 4000 | 3640 | 1500 | 2800-4000 | 1500-2700 | 1200 | |

Features of Manual Portable Gantry Crane

- High mobility: Equipped with omnidirectional casters with brakes, the gantry frame offers flexible transport, allowing for multi-directional movement of hoisted items on flat surfaces or stationary lifting of heavy objects.

- Simple operation: Movement is achieved through manual pushing; the equipped manual or electric lifting device is easy to control, reducing the difficulty and intensity of manual labor.

- Low maintenance cost: Simple structure with few vulnerable parts; regular inspection and maintenance are sufficient to maintain good condition.

- High flexibility: Width and height can be adjusted in stages to meet various operational needs. When factory height is limited, a low-headroom electric hoist can be equipped for easy ultra-low-altitude operations.

- High safety performance: Designed with anti-tipping measures to ensure stability during operation, and it also features multiple safety protection mechanisms, including anti-detachment devices, overload protection, and emergency stop buttons.

Applications of Manual Portable Gantry Crane

|

|

|

|

|

| Machining | Car repair and maintenance | Heavy cargo warehousing | Construction | Production line |

| Ransferring heavy workpieces (shafts, discs, housings) between machine tools and workstations. Disassembly/installation/replacement of heavy components such as machine tool spindles, gearboxes, and motors. |

Lifting, disassembling, and repositioning of car/truck engines and transmissions. Lifting of heavy-duty automotive chassis components, such as drive shafts and shock absorbers. |

Lifting, disassembling, and repositioning of car/truck engines and transmissions. Lifting of heavy-duty automotive chassis components, such as drive shafts and shock absorbers. |

Hoisting and transporting precast concrete slabs, reinforcing steel frames, and small steel structural components. On-site hoisting and installation of construction equipment such as electrical distribution boxes, water pumps, and small motors. |

Production line equipment debugging, mold hoisting and transfer, or precision instrument positioning. |

Material Comparison of Manual Portable Gantry Crane

|

|

|

| Carbon steel (Q235B/Q345B) | Stainless steel (304/316L) | Aluminum alloy (6061-T6/7075) |

|

Carbon steel is the mainstream material for manual gantry cranes, paired with I-beam main beams, channel steel, and square tube legs. |

Combined with square tubing and I-beams in the structure. |

Uses high-strength profiles in tubular or box-shaped structures. |

Case of Manual Portable Gantry Crane

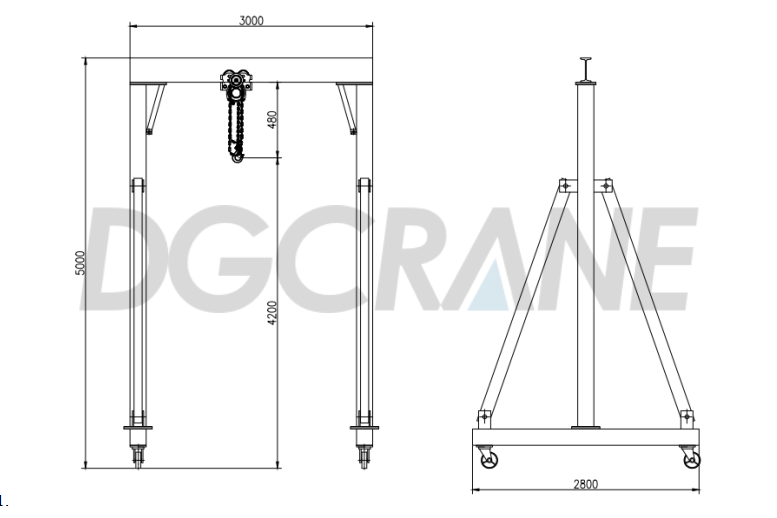

Basic parameters:

- Capacity: 5t

- Span: 4m

- Lifting height: 4m

- Hoist: electric chain hoist

- Hoist travelling speed: 2.7 m/min

- Crane travelling speed: manual

- Voltage: AC 3Ph/380V/50Hz

features:

- Height can be adjusted within the technical range.

- Height adjustment and lifting operations can be carried out simultaneously.

- The casters are equipped with braking devices, providing moderate resistance.