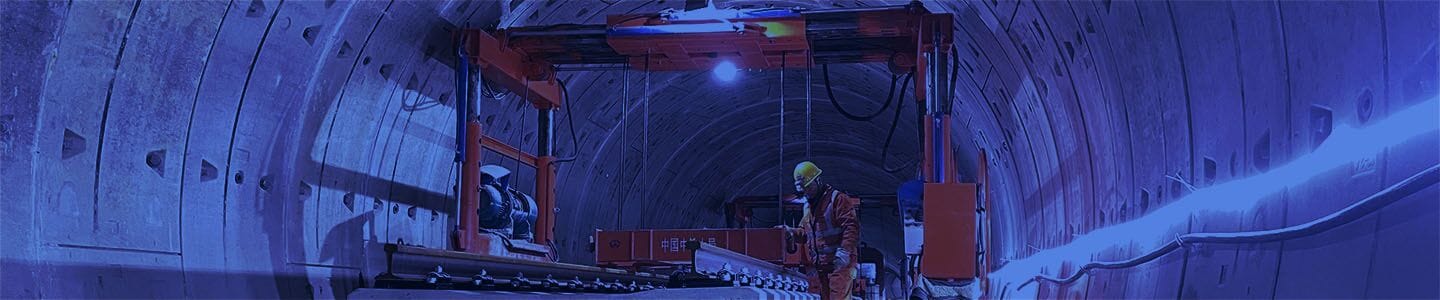

Subway Track Laying Gantry Crane for Tunnel Track Installation

Subway Track Laying Gantry Crane is a type of crane specially designed for subway track construction. It is mainly used in subway projects for track laying and maintenance, including rail panel lifting, as well as the lifting and installation of formwork, reinforcement steel, and other materials. The working environment is typically confined spaces such as subway tunnels.

The span and height of the gantry crane are adjustable. It can operate in a dual-machine combined mode, synchronously completing the installation of 25-meter rail panels, or work independently to lift concrete and other individual components.

Subway Track Laying Gantry Crane Introduction

The Subway Track Laying Gantry Crane lifting mechanism adopts CD1/MD1 electric wire rope hoists, featuring a simple structure, stable performance, and robust durability, operating in coordinated lifting mode. The gantry crane traveling mechanism is driven by vertical drive units, with each drive operating independently. The control system supports single-crane operation or multi-crane synchronized linkage control.

The gantry crane adopts a compact box-type structure. Its span and lifting height are adjustable to suit the confined space conditions inside subway tunnels. During operation, it mainly works in multi-crane coordinated lifting mode, ensuring safe, efficient, and stable track-laying operations.

Subway Track Laying Gantry Crane Features

- Automatic Adjustable Span and Height: The hydraulic system enables adjustment of the overall height and traveling span. The height adjustment range is 3100–3600 mm, and the span adjustment range is 3000–3900 mm.

- Compact Structure: Adopts a compact box-type structure, making it suitable for operation in confined spaces such as subway tunnels.

- Easy Operation: Simple installation and operation, smooth running performance, and low maintenance cost.

- Adjustable Traveling Speed: Meets different construction rhythms and improves material handling efficiency.

- High Versatility: Applicable to various types of subway tunnel track engineering projects.

- Flexible Operation Modes: Supports single-crane operation or dual-crane coordinated operation. In single-crane mode, it can be used for lifting concrete and other individual materials; in dual-crane mode, two cranes can synchronously complete the installation of 25 m rail panels.

- Integrated Transfer and Transportation: The crane can pass through platforms, platform screen doors, small-radius curves, and connecting passages, allowing overall transportation and relocation within the tunnel without disassembly.

Applicable Environment

- Applicable Altitude: ≤ 2000 m

- Ambient Temperature: -25°C to +40°C

- Relative Humidity: 55%–85%

- Flammable Gas Concentration: Not exceeding 10% of the lower explosive limit (LEL)

Subway Track Laying Gantry Crane Parameters

| Rated Lifting Capacity | 10000kg | 16000kg |

| Span Adjustment Range | 3m~3.9m | 3m~3.9m |

| Height Adjustment Range | 3.1m~3.6m | 3.1m~3.6m |

| Lifting Speed | 4 m/min | 4 m/min |

| Traveling Speed | 3~30 m/min | 3~30 m/min |

| Power Supply Mode | Cable Reel | Cable Reel |

| Power Supply | Three-phase 380V 50Hz | Three-phase 380V 50Hz |