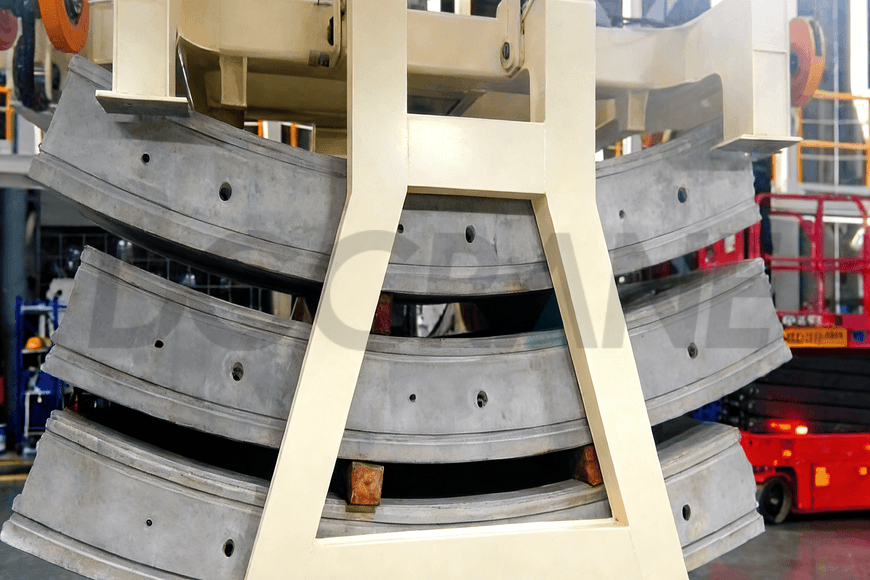

Segment Handling System for Concrete Segments in Shield Tunnel Construction

The Segment Handling System is specially designed to work with tunnel boring machines (TBMs), capable of lifting, rotating, and transporting segments and box culverts. It is an essential solution for safe and efficient shield tunneling operations.

This system can be customized according to the TBM cutterhead diameter and actual working conditions, supporting the handling of single or multiple segments as well as box culverts. The Segment Handling System features a compact structure, smooth lifting operation, and precise positioning. It is equipped with PLC control, hydraulic grasping, automatic acceleration and deceleration, safety interlock, mechanical positioning, slope climbing, over hinge point, safety braking, etc.

Segment Handling System Features

Designed for Shield Tunneling

- Specifically developed for shield tunneling projects, capable of lifting, rotating, and transporting segments and box culverts, ensuring construction safety and efficiency.

- Can be customized according to the TBM cutterhead diameter and on-site conditions to meet the requirements of different projects.

Versatile Handling Capability

- Supports single-segment lifting as well as multiple-segment or box culvert handling, improving construction efficiency.

- Smooth lifting operation ensures segments remain undamaged during transportation.

Compact Structure and Reliable Safety

- Compact overall design, ideal for working in confined tunnel spaces.

- Uses hydraulic gripping, offering higher safety compared to vacuum suction-based lifting systems.

Intelligent Control System

- Integrated System: Establishes a centralized equipment information platform with the ASW system at its core, connecting upstream to the MES management system and downstream to handling and lifting sensors for highly integrated information flow.

- Digitalized Management: Real-time production data is collected across the plant via a comprehensive network platform, allowing operators to quickly monitor crane operation status and seamlessly link production processes with information systems.

- Data Analytics: Equipment data is centrally stored and analyzed to assist management in identifying issues, issuing risk warnings, and supporting data-driven decision-making.

- Reliability: Optimized mechanical design, simulation analysis, material selection, and electrical component configuration ensure long-term stable operation of the equipment.

- Safety: Specialized safety measures and self-diagnostic technologies ensure the system only starts after preparation is complete. Brake switches, torque verification, and braking logic guarantee safe crane operation.

Safety Protection

Anti-Collision & Collision Protection

- Utilizes infrared, laser, and ultrasonic technologies to reliably control crane movement, providing effective braking when approaching objects within 3 meters at the same elevation.

- If the braking distance is exceeded, the ASW system can automatically slow down and stop the crane to prevent secondary impact, effectively protecting both the object and surrounding equipment.

- Supports configurable restricted zones, such as production machinery or storage areas. The crane is prevented from entering these zones and will automatically stop if it does, helping prevent collisions with valuable equipment and enhancing overall safety.

Safety Monitoring

- Built-in safety monitoring system tracks key operating data, including start counts, brake engagement, overload events, cycle counts, and total operating hours, providing comprehensive oversight of the crane's lifecycle.

- Continuously monitors system voltage, current, and lifting load to prevent overvoltage, overcurrent, overload, and other faults, with all data uploaded to a big data platform for analysis.

Anti-Sway & Tilt Protection

Real-time tilt sensor data prevents accidents or equipment damage caused by excessive sway or tilt when lifting heavy loads.

Segment Handling System Specifications

Single Segment Handling System

| Lifting Mechanism | Lifting Capacity | 20 t (4 t for lifting device + 16 t for load) |

| Lifting Speed | 8 m/min | |

| Lifting Height | 6 m | |

| Trolley Travel Mechanism | Travel Speed | 30 m/min, slope ±5% |

| Rotating Lifting Device | Rotation Speed | 1.15 r/min |

| Rotation Angle | ±90° | |

| Hoist | Lifting Capacity | 1600 kg |

| Lifting Speed | 4.0 / 1.3 m/min |

Multiple Segment Handling System

| Lifting Mechanism | Lifting Capacity | 40 t (8 t for lifting device + 32 t for load) |

| Lifting Speed | 8 m/min | |

| Lifting Height | 10 m | |

| Control Method | Remote + Wired | |

| Trolley Travel Mechanism | Travel Speed | 50 m/min, slope ±5% |

| Translation Mechanism | Translation Distance | ±400 mm |

Box Culvert Handling System

| Lifting Mechanism | Lifting Capacity | 25 t |

| Lifting Speed | 5 m/min | |

| Lifting Height | 10 m | |

| Control Method | Remote + Wired | |

| Trolley Travel Mechanism | Travel Speed | 50 m/min, slope ±5% |

| Translation Mechanism | Translation Distance | ±300 mm |