Egypt Overhead Crane Market: Key Industry Demand and Suppliers

Table of Contents

Egypt is rich in resources such as oil, natural gas, phosphates, and iron, and has a relatively complete industrial system, creating a stable demand for lifting equipment. Industries such as oil and gas, steel, textiles, and large-scale industrial projects all require efficient and safe overhead cranes to ensure smooth material handling, installation, and production operations. This article introduces the demand for overhead cranes in Egyptian major industries and provides an overview of the overhead crane supply situation.

Main Industry Demand for Overhead Cranes in Egypt

Petroleum & Gas Industry

Egypt is a key oil and gas producer in Africa, with the oil and gas sector accounting for approximately 25% of its GDP. According to the Energy Institute (EI) of the UK, Egypt oil production in 2023 reached 29.8 million tons, and natural gas production was 57.1 billion cubic meters. The country has 11 oil refineries, making its refining capacity the highest in Africa. According to Mordor Intelligence, the Egyptian oil and gas market is expected to reach around USD 7.71 billion in 2025 and approximately USD 8.94 billion by 2030.

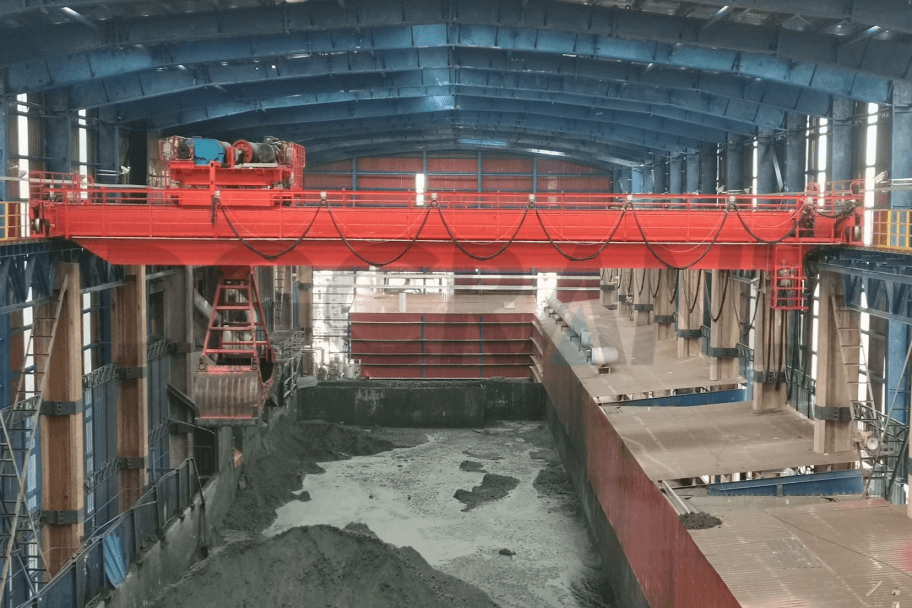

In hazardous environments such as oil, gas, and refining plants, where flammable gases, steam, or combustible dust are present, explosion-proof overhead cranes are required for lifting, installation, and maintenance operations. In coking plants, coking cranes are needed to move hot coke from the coke pits into coke buckets and transport the cooled and dehydrated coke to crushers, hoppers, or conveyors.

Textile Industry

Egypt has the largest cotton and textile industrial cluster in Africa. In the country's manufacturing sector, the textile industry is considered the second-largest industrial sector, with a relatively complete industrial chain covering cotton cultivation, spinning, weaving, and garment manufacturing. Currently, there are around 7,000 textile enterprises in Egypt, and the added value of the textile industry accounts for approximately 3% of GDP.

In textile production, materials such as raw cotton, yarn coils, fabric rolls, and dyes or chemicals need to be transported between different workshops and production stages. Overhead cranes can improve handling efficiency and ensure operational safety. Common types of overhead cranes used include single girder and double girder bridge cranes.

Steel Industry

Egypt is the largest steel producer and consumer in Africa. In 2023, steel production in Egypt reached 10.4 million tons, with steel imports valued at USD 4.22 billion, accounting for 5.1% of total imports, and exports at USD 2.33 billion, accounting for 5.5% of total exports. The steel industry is expected to reach a market size of approximately USD 4.482 billion by 2033.

Steel plants involve high-temperature and heavy-duty operations in smelting, casting, rolling, and storage, handling materials such as ladles, steel coils, and structural steel. Overhead cranes are required for high-strength lifting in these processes. Common types of cranes used include double girder overhead cranes, ladle overhead cranes, electromagnetic overhead cranes, and clamp overhead cranes.

Local Overhead Crane Suppliers in Egypt

MISR for Engineering Works

MISR for Engineering Works was established in 1983 and is headquartered in Cairo, Egypt. It is a professional manufacturer and supplier of overhead cranes and serves as the exclusive agent for the GH and HADEF brands in Egypt. The company operates two crane manufacturing factories with a total area of 1,500 square feet and has obtained ISO 9001:2005 and OHSAS 18001:2007 certifications. Its main products include overhead cranes, gantry cranes, monorail cranes, jib cranes, as well as wire rope hoists and chain hoists, which are widely used in seawater desalination plants, wastewater treatment plants, metro construction, shipyards, and other industrial sectors.

EGYPTIAN NORWEGIAN CRANES

EGYPTIAN NORWEGIAN CRANES was established in 2003 and is located in New Fustat, Cairo (120, 2nd Neighbourhood, New Fustat, CAIRO). The company has decades of experience in manufacturing overhead cranes and specializes in electric and manual cranes, single girder and double girder bridge cranes, monorail cranes, gantry cranes, and jib cranes. It serves as an agent and distributor for MISIA (Italy), U-MEGA (Taiwan), YALE (Germany), and MUNCK (Norway). The company has supplied equipment to steel plants, cement plants, power plants, and water treatment plants, providing comprehensive installation and after-sales services.

Modern Trading

Modern Trading Company is located in Cairo, Egypt. It is a supplier and service provider of lifting equipment, primarily representing products from the Turkish company Arnikon Engineering and Crane Systems. The company offers overhead cranes, gantry cranes, jib cranes, crane kits, and spare parts, while also providing local steel structure fabrication, installation, maintenance, and technical support services. It is dedicated to delivering high-quality material handling and lifting solutions to various industrial sectors in Egypt.

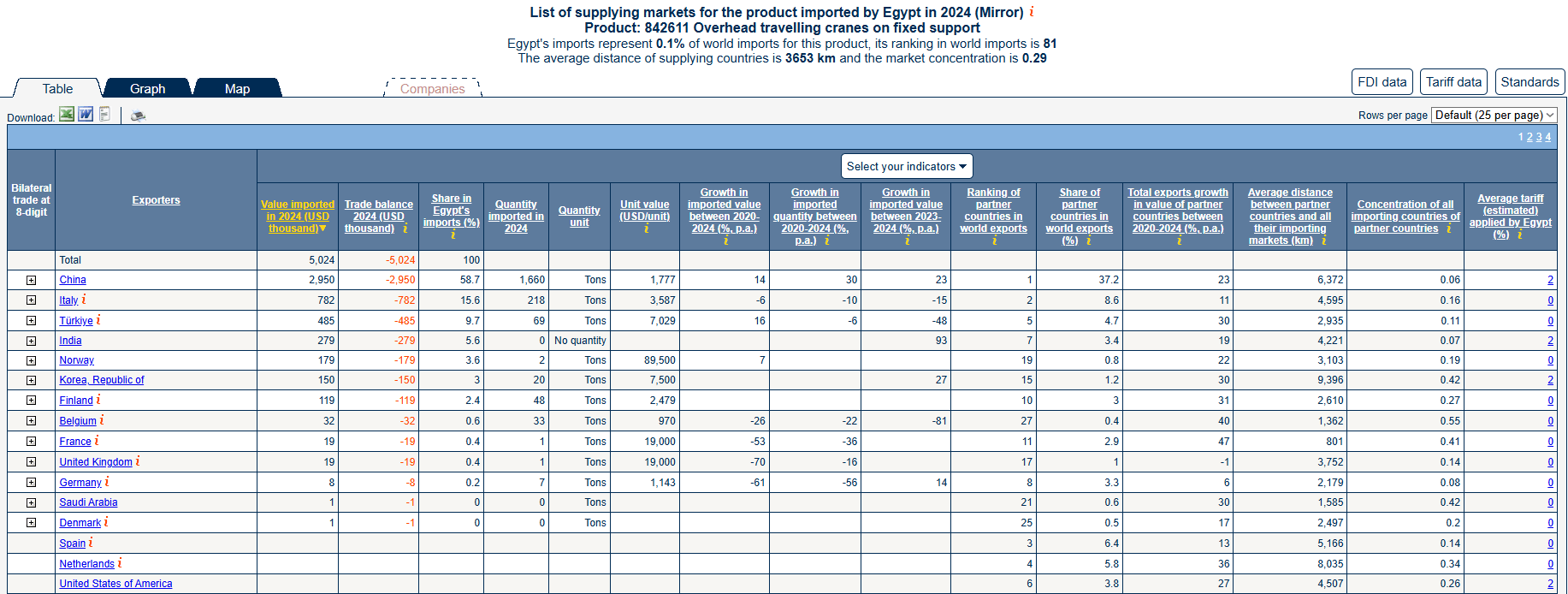

Egypt Overhead Crane Imports Market Overview: China Is the Largest Supplier

According to the data from ITC Trade Map, China, Italy, and Turkey are the top three suppliers of overhead cranes to Egypt. Among them, China ranks first, accounting for the largest share of Egypt total imports, followed by Italy and Turkey.

Italy and Turkey are geographically close to Egypt, giving them certain advantages in logistics, delivery time, and after-sales response speed, along with greater flexibility and cost efficiency. Turkish crane manufacturers offer a wide range of products—from single-girder and double-girder overhead cranes to gantry cranes—with increasingly mature production capabilities. Most companies hold CE and ISO certifications and comply with FEM and DIN standards. The Italian crane and lifting equipment industry is characterized by high precision and reliability, with strong expertise in automation control and precision manufacturing.

Chinese overhead cranes are valued for their extensive product range, stable performance, and high cost-effectiveness. Chinese suppliers can provide complete lifting solutions, including light-duty single-girder cranes, heavy-duty double-girder cranes, metallurgical cranes, explosion-proof cranes, and European-standard series. These solutions are suitable for a wide range of industries, including oil and gas, metallurgy, steel, textiles, power, cement, chemicals, ports, and water treatment.

Moreover, Chinese crane manufacturers benefit from a well-developed industrial chain and large-scale production capabilities, giving them strong competitiveness in delivery times, cost control, and spare parts supply. With the deepening industrial cooperation between China and Egypt under the Belt and Road Initiative, Chinese crane companies have been continuously enhancing their local service capabilities and brand influence in Egypt, becoming a key driving force in the country's industrial modernization.

DGCRANE: A Chinese Overhead Crane Supplier

- Location: Based in Changyuan City, Henan Province, China—the largest crane manufacturing hub in the country. The area offers abundant raw materials and components, facilitating procurement and production, and brings together a large pool of experienced crane design and manufacturing talent. This ensures high production efficiency, reliable quality, and fast delivery.

- Products: Up to 800t overhead cranes, up to 800t gantry cranes, jib cranes, hoists, transfer carts, crane parts, and lifting devices.

- Industries Served: Steel, oil and gas, textiles, precast concrete plants, waste treatment, automotive, ports, general manufacturing, food and beverage, paper mills, hydroelectric power plants, and more.

- Quality Certifications: Products comply with international standards such as ISO, CE, and EN, and have obtained ISO, CCC, CE certifications. Additional certifications available include ISO9000, CCC, TüV, UL, CE, RoHS, and SGS.

- Industry Experience: DGCRANE has over 15 years of experience in the design, manufacturing, and export of overhead cranes. Products have been sold to over 120 countries, completing more than 3,000 projects across various industries.

- Services: DGCRANE provides comprehensive services for clients, including free crane design, professional installation and after-sales support, spare parts supply, and project consultation, assisting clients in completing lifting operations efficiently and safely.

DGCRANE Cases in Egypt

5 Ton Single Girder Overhead Crane Exported to Egypt

- Capacity: 5t

- Span length: 23m

- Lifting height: 8m

- Lifting mechanism: electric wire rope hoist

- Control mode: control pendant+remote control

- Power source: 380 V/50 Hz/3 PH

- Work duty: ISO M5

Our engineers precisely calculate the bridge crane's span and lifting height based on the factory layout provided by the client, ensuring that the equipment fully matches the on-site conditions. During the shipping stage, the main beam was cut twice to fit the dimensions of a 40-foot container, allowing smooth transport. This approach ensures safe and efficient transportation while making on-site assembly convenient for the client upon delivery.

Single Girder Overhead Cranes Exported to Egypt

- 7 sets of European single girder overhead crane

- 2 sets of freestanding single girder overhead crane

Our engineers precisely calculated the bridge crane's span and lifting height based on the factory layout provided by the client, creating a customized design that perfectly suits the on-site conditions.

During the shipping stage, the equipment structure was carefully divided and loaded into two 40-foot open top containers. This approach ensured the integrity of the main components while facilitating quick on-site assembly.

The entire process—from design and manufacturing to shipment—was closely coordinated to ensure the product reached the client's facility safely and smoothly.

Explosion-proof Overhead Cranes Exported to Egypt

- Load capacity: 15t

- Crane Span: 11.1m

- Lifting height: 24m

- Control mode: handle and wireless remote control

- Power source: 380 V/50 Hz/3 Phase

- Work duty: A5

To ensure the crane arrives at the client's facility in perfect condition, the main beam was wrapped in waterproof tarpaulin, and all related accessories and electrical components were packed in dedicated export wooden crates. Each stage of the crane's production, packaging, and shipment was managed by dedicated personnel, with every effort made to achieve the highest level of precision.

Conclusion

Local overhead crane suppliers in Egypt can meet basic lifting requirements, with relatively lower additional costs such as transportation and taxes, and they also offer advantages in after-sales service and response speed. Suppliers from neighboring countries are geographically close to Egypt, making logistics and transportation more convenient. Chinese crane suppliers offer higher cost-effectiveness, complete product ranges, and good quality. By comprehensively considering project scale, budget, schedule, and technical requirements, clients can select the supplier that best fits their needs, ensuring efficient, safe, and long-term value from their overhead crane investment.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!