Electrolytic Copper Cranes: Cathode and Anode Handling in Copper Electrolysis Lines

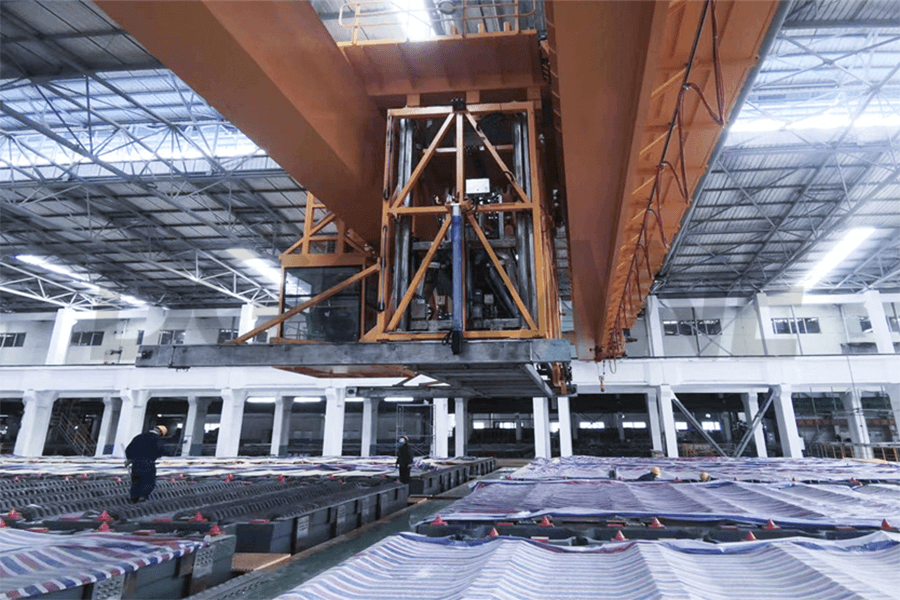

Electrolytic copper crane is a specialized crane developed and manufactured to meet the process requirements of electrolytic copper production. It is designed to operate reliably in harsh environments characterized by high humidity, corrosive conditions, and metal dust, and is capable of precisely gripping, transferring, and positioning cathode and anode plates within electrolytic cells.

Applications and Functions of Electrolytic Copper Cranes

Electrolytic copper overhead cranes are mainly used in copper electrolysis workshops to carry out key operations such as anode plate loading into electrolytic cells, cathode copper plate unloading, electrode plate stacking and transfer, as well as heavy lifting tasks for inspection and maintenance of electrolytic cells. They are capable of operating stably in the high-humidity and highly corrosive environment of electrolysis workshops, enabling efficient, precise, and safe handling of anode and cathode plates. As such, they are indispensable core equipment in the continuous and large-scale production of electrolytic copper.

Electrolytic copper multifunctional cranes mainly perform the following functions:

- Lifting pre-arranged anode and cathode plates from the spacing machine unit and transporting them to empty cells for installation into the electrolytic tanks.

- After electrolysis is completed, removing the cathode plates and transferring them to the washing unit.

- Removing spent anode plates from the electrolytic cells and delivering them to the washing unit.

Features

- Reinforced main girder design to improve mechanical performance and load capacity.

- Synchronized main hoisting mechanism equipped with anti-rope-tangling and anti-wear devices.

- Automatic crane travel positioning with rail anti-climbing function, improving positioning accuracy of the crane and trolley as well as the dedicated lifting device, enabling accurate engagement of special lifting tools.

- Automation control system supporting remote network control of the crane, providing operation monitoring, fault indication, and corrective guidance to improve operational intelligence.

- Emergency manual control system provided, allowing safe and stable operation of the special crane in case of communication failure.

- Electrical insulation design ensures safe operation and maintenance of the crane and lifting devices over high-current electrolytic cells.

- Multiple control modes, including operator cabin control, remote control, and ground control station, ensuring clear visibility of lifting conditions and supporting automated production lines in the workshop.

Specialized Spreader for Electrolytic Copper Cranes

Electrolytic Copper Dedicated Lifting Device is designed for the automatic loading and unloading of cathode plates (starting sheets) and anode plates in electrolytic cells. It features multiple functions, a high level of automation, reliable insulation, and stable performance. The main structure is manufactured from high-quality stainless steel, offering high strength and resistance to acidic corrosion.

Main features include:

- Specially designed plate-arranging function and plate-tapping device to ensure smooth insertion of starting cathode plates into the electrolytic cells.

- Capable of independent lifting of cathode plates and anode plates, as well as combined lifting of multiple plates, providing high operational efficiency.

- Combination of pre-positioning and fine positioning, with a positioning accuracy of ±2 mm.

- Flat-push type electrolyte drip tray with smooth opening and closing, ensuring that electrolyte does not splash.

Technical Specifications

| Span (m) | 31.5 | |

| Duty Class | A8 | |

| Lifting Capacity (t) | 4×8 (including spreader) | |

| Lifting Height (m) | 6.5 | |

| Lifting Speed (m/min) | 2–20 | |

| Trolley Travel Speed (m/min) | 4.5–45 | |

| Crane Travel Speed (m/min) | 1.6–160 | |

| Electric Hoist (Aux. Hook) | Lifting Capacity (t) | 3 |

| Lifting Speed (m/min) | 8 | |

| Travel Speed (m/min) | 20 | |

| Speed Control Type | Crane Travel | Variable Frequency Drive (VFD) |

| Trolley Travel | Variable Frequency Drive (VFD) | |

| Spreader | Variable Frequency Drive (VFD) | |

| Max. Wheel Load (KN) | 220 | |

| Crane Rail (Recommended) | QU100 | |

| Total Power (KW) | 270 | |

| Operation Mode | Cabin (with heating/cooling A/C), movable with trolley | |