Hoist & Winch Trolley

Usually, electric hoists will not used alone. They are often mounted on single girder overhead crane, monorail crane, jib crane and single girder gantry crane as the lifting part. If your need to hoisting some project and move it to another place, please select a proper crane, rather than only a hoist. Typically, there are many kinds of electric hoists for sale in DGCRANE, we provide you: electric wire rope hoist and electric chain hoist. Of course, electric hoists are independent part, it can works on it own.

Wire rope hoist vs chain hoist

What criteria should it apply to choosing an electric hoists for sale: electric wire rope hoist OR electric chain hoist. A lot of people are confused at this. A miss application of these electric hoists is serious, and you will pay for it. So, take it serious, and read further on this question.

There are some main factors you need to concern:

- Capacity – Just as shown in the table above, the electric chain hoist is mainly used in under 5 ton, and the electric wire rope has a bigger capacity range. Also there are some electric hoist has a higher capacities, it is special for special applications. Here, we just briefly talk about the difference between them. For more information, you can just check it out from our engineers.

- Application – Due to the structure of chain hoist, the chain must move up and down straightly. While, the rope run around the hoist drum in wire rope hoist, so it can hoist the load at certain angle.

- Duty group – Also, electric chain hoist has almost the same duty group compared with the electric wire rope hoists shown in the table. In fact, due to the structure of gear and chain, it is not very suitable for very frequent use which will create heat in the gears and will wear out quickly.

- Price – Generally speaking, chain hoist cost less than the corresponding electric wire rope hoists and has a less maintenance costs.

Production efficiency – The electric wire rope hoists has a faster lifting speed and a higher production efficiency.

Rich Industrial Experiences

We can provide you with various optional functions according to the special lifting needs in your industry, such as electronic anti-sway, remote monitoring, lifting synchronization and other functions. These are just a part of them.

Product Design Specifically for Export

Crane and Plant Integration Solutions Are Available

We don't just have cranes and other lifting products, we also offer a one-stop shop for custom steel buildings.

Adaptation to Special Plant Environments

We can meet the needs of factory environ-ments from -30 to 50 degrees Celsius, or for cranes with explosion-proof requirements.

Customized Voltage Supply

We can customize the generator to meet the different voltage requirements around the world, whether the voltage in your country is 100V~130V or 220~240V. Alternatively, generators are available.

Adequate Accessories

We are well equipped with spare parts that not only compress the production cycle and improve productivity, but also enable timely response in after-sales maintenance.

Flexible Procurement Programmes

- Transport Costs

- Cross Girder

- Other Parts

- Equipments Costs

- Cross Girder

- Other Parts

Complete plane

Component plane

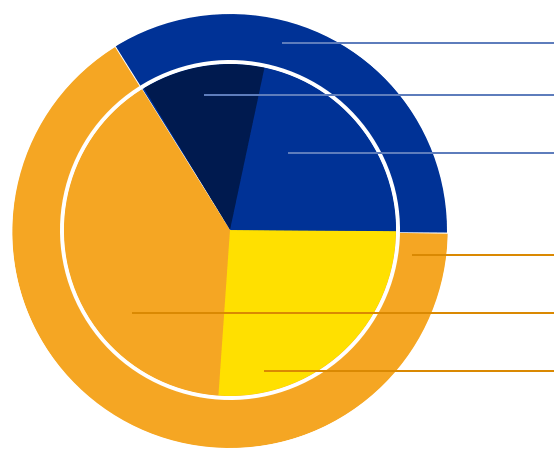

Transport Cost Analysis

As shown in the Overhead Crane Costs Pie Chart (left), transport costs account for a significant portion of expenses, with the cross girder being the primary contributor. By addressing this cost driver, we offer two tailored solutions: Complete Crane and Component Crane packages.

Complete Overhead Crane Package

- Full System Delivery: Includes pre-assembled trolley, cross girder, end trucks, electrification systems, and all necessary components.

- Factory-Tested Reliability: Fully assembled and rigorously tested in our facility to ensure operational readiness.

- Easy Installation: Disassembled for shipping, then quickly reinstalled on-site with minimal effort.

- Best For: Clients prioritizing convenience, time savings, and hassle-free deployment.

Component Overhead Crane Package

- Exclusions: Cross girder (to be sourced locally by the client).

- Key Benefits:

- Reduced Transport Costs: Eliminate bulky cross girder shipping expenses.

- Local Flexibility: We provide detailed engineering drawings, 3D models, and step-by-step guidance for local cross girder fabrication.

- Best For: Cost-conscious clients with access to local steel resources or fabrication capabilities.

Application Cases

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!