Premium Rope Guide for Electric Hoists: Durable Nylon, Cast Iron & Rebar Options

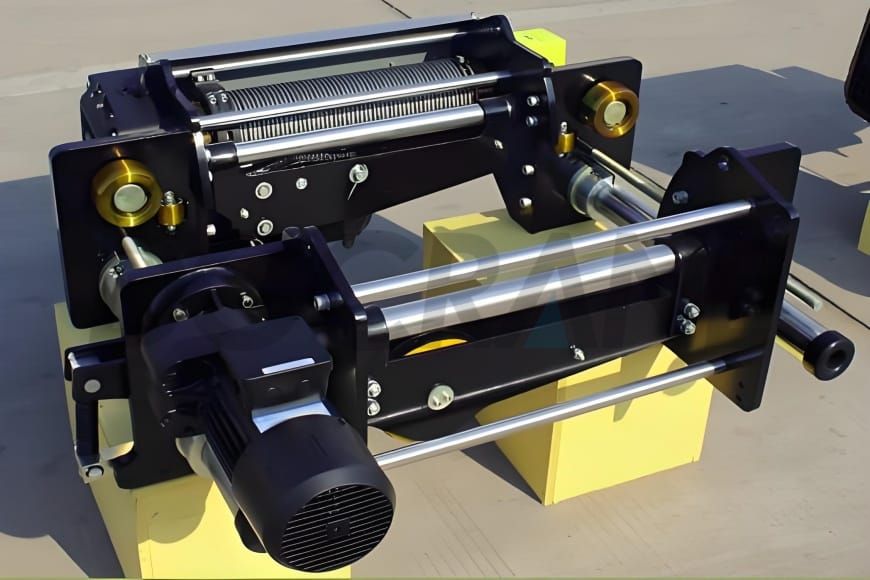

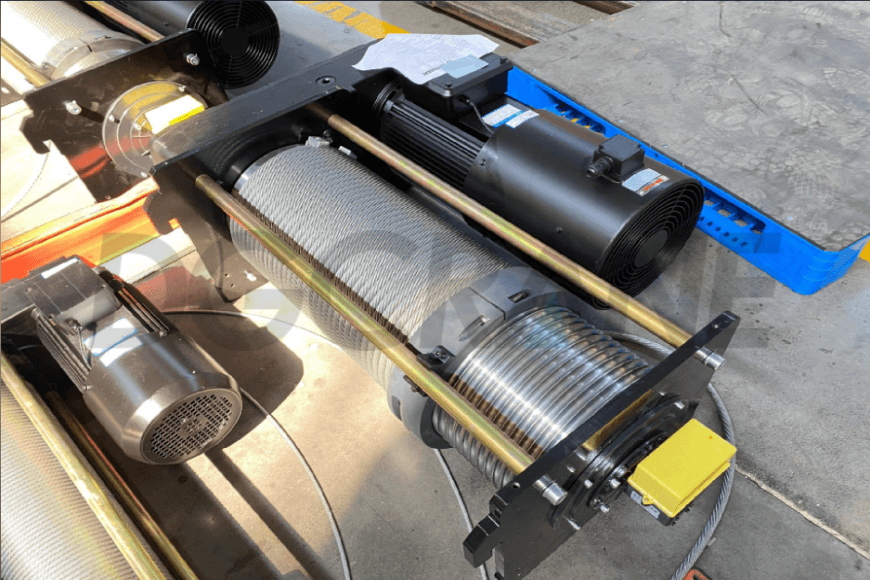

Rope Guides on electric wire rope hoists serve the function of guiding and arranging the wire rope. Based on the material, rope guides can be classified into cast iron rope guides, nylon rope guides, and rebar rope guides.

Working Principle of Rope Guide

The rope guide itself does not rotate. When the drum rotates and the wire rope winds, the helical groove drives the rope guide to move axially, guiding the wire rope in and out of the drum's helical groove accurately. The wire rope is expelled through the notch of the rope guide. Since the rope guide is subjected to significant lateral force during operation, it is prone to breaking and is one of the most vulnerable components on a hoist.

Nylon Rope Guide

Nylon rope guides are available in sizes such as 1t, 2t, 3t, 5t, 10t, 16t, and 20t, with non-standard customization available.

Features

- Made from nylon, it is lightweight, strong, wear-resistant, and easy to carry.

- A rectangular opening on the connection plate allows installation without removing the wire rope, unhooking the hook, or disassembling the wire rope.

- This rope guide consists of two complete loops, ensuring no misalignment or skewed positioning during installation.

Applications

Nylon rope guides are made of high-strength, wear-resistant nylon and are suitable for use on European-style electric hoists.

Cast Iron Rope Guide

Cast iron rope guides are available in sizes such as 0.5t, 1t, 2t, 3t, 5t, 10t, 16t, 20t, and 30t.

Features

- Molded from gray cast iron, it has a sturdy structure, high wear resistance, and strong versatility.

- It is durable, with a high load-bearing capacity, suitable for heavy-duty environments, requiring minimal maintenance and low costs.

- Exhibits good vibration damping, machinability, and low notch sensitivity.

Applications

CD1 and MD1 type electric wire rope hoists primarily use circular cast iron rope guides.

These hoists are widely used in scenarios requiring high strength and wear resistance. Due to their exceptional strength, wear resistance and corrosion resistance, cast iron rope guides effectively guide and protect the wire rope, ensuring smooth operation under various complex conditions.

Rebar Rope Guide

Rebar rope guides are available in sizes such as 0.5t, 1t, 2t, 3t, 5t, 10t, 16t, 20t, and 30t.

Features

- Manufactured from high-strength steel, making it lighter and more durable than cast iron rope guides.

- Offers higher wear resistance and load-bearing capacity while being lighter and more cost-effective.

Applications

Rebar circular rope guides are also used in CD1 and MD1 type hoists.

Performance Requirements for Crane Rope Guides

- Ensure smooth entry and exit of the rope.

- Securely press the rope to prevent it from jumping out of the groove.

- Allow smooth movement and arrangement of the rope without tangling.

- Enable easy installation, removal, and maintenance.

- Be wear-resistant.

- Ensure that the wire rope maintains a certain angle along the drum's axis without interference between drums.

- When used in conjunction with the lifting limit switch, it should ensure reliable limiting functions.

Rope Guide Installation Method

- Remove the fixing screws from the rope guide.

- Expand the rope guide, orienting the side with the lip outwards, and insert the rope guide into the hoist.

- Thread the wire rope head through the rope guide, adjust the rope guide, and straighten the wire rope winding sequence.

- Insert the wire rope head into the fixed post and secure it with an iron wedge.

- Secure the rope guide and fasten all fixing screws.

- Start the hoist and adjust the rope guide. Ensure the rope guide can accurately trip the limit switch without allowing the wire rope to slacken for optimal performance.