Overhead Cranes for Food and Beverages: Ideal for improving productivity and food safety

In the food and beverages processing industry, the role of lifting equipment is indispensable. As production scales expand and automation levels rise, lifting equipment not only enhances operational efficiency but also ensures safety and stability in the production process.

Whether it’s in raw material handling, packaging procedures, or during finished product storage and distribution, professional cranes and other lifting equipment play a vital role. Especially in environments that are slippery, high-temperature, or have strict hygiene requirements, the right lifting equipment can significantly reduce the risks of manual operations and ensure a smooth production process.

Choosing lifting equipment that is specifically suited for the food processing industry has become a key factor for companies aiming to improve productivity, ensure product quality, and maintain safety standards.

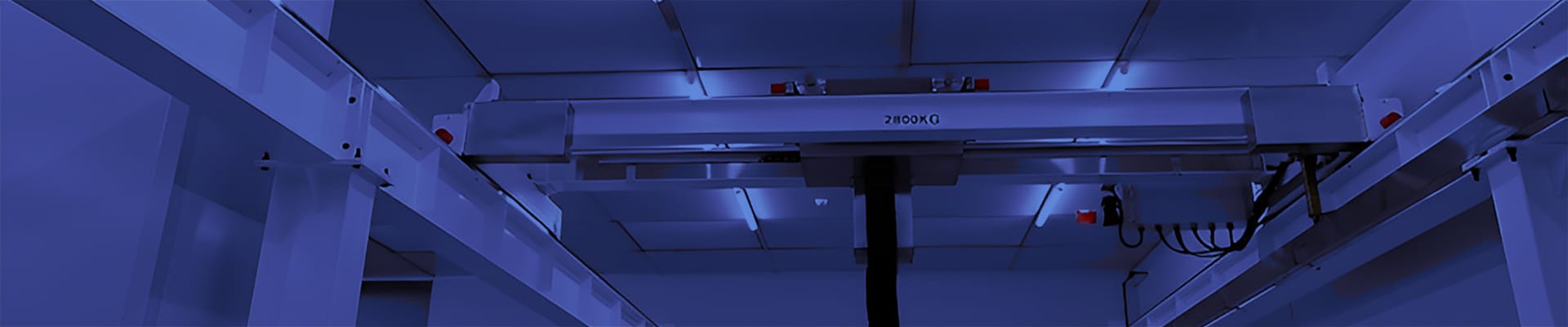

Cleanroom Cranes

Features:

- Hygienic Design

Constructed using easy-to-clean materials and designs that effectively prevent the growth of bacteria and other microorganisms. The smooth surfaces and dead-angle-free structure make cleaning tasks easier and more efficient. Excellent sealing performance also prevents external contaminants from entering the production area, maintaining a clean and sanitary environment. - Stainless Steel Trolley Track

The trolley running track is made of stainless steel, which reduces wear and corrosion during trolley operation. This significantly minimizes debris generation from the electric hoist during repeated use. - Anti-Static Main Girder

An anti-static device is installed on the main steel structure girder to prevent the accumulation of static electricity, thus avoiding dust and hair adhesion issues. - Stainless Steel Wheels with Anti-Corrosion Coating

The crane uses stainless steel wheels coated with an inorganic anti-corrosion layer. This helps reduce wheel wear and prevents debris from falling off during operation. - Inorganic Anti-Corrosion Coating

The selected coating is a water-based zinc-chromate layer. It offers excellent corrosion resistance without causing hydrogen embrittlement. Suitable for high-strength, stress-bearing components, it can withstand temperatures up to 300°C. It is highly adaptable for use in structural parts, is pollution-free, and safe for use. - Stainless Steel Hook

The hook is primarily made of stainless steel, meeting the DIN 15401 standard. This ensures that hooks, slings, and lifting straps do not generate excess particles due to friction. - High-Strength Fiber Rope

The lifting rope is made of high-strength synthetic fiber. It is lightweight, strong, wear-resistant, fatigue-resistant, has low elongation, and strong flexibility. The surface is coated with a conductive resin to discharge static electricity. No friction dust is generated during hoisting operations. - Corrosion-Resistant Polyurethane Finish

The main body of the crane is coated with an anti-corrosive, low-friction polyurethane topcoat. This paint has excellent gloss retention, is non-tacky, and offers strong resistance to chemicals and water.

Product Types

- Single girder structure with relatively lower load capacity, suitable for lighter lifting tasks.

- Typically features a smaller span, making it ideal for medium to small factories or operations in confined spaces where a limited working range is required.

- Simple structure and lower cost.

- Double girder structure with higher load capacity, suitable for handling heavier materials or performing heavy-duty lifting operations. The twin-girder design allows for more even load distribution, making it ideal for high-load tasks.

- Larger span, suitable for spacious production areas or wide-span requirements. It can cover a broader working area, making it ideal for large factories or environments with high-span needs.

- It occupies minimal floor space, with its working range achieved through a rotating arm, allowing for efficient use of vertical space. This makes it especially suitable for production workshops with limited space. It enables flexible operation within a small working area, improving space utilization efficiency.

- Supported by legs and a horizontal beam with a wheeled base, suitable for movement on the ground

- Open space operation with ground mobility, no overhead track required

- Large moving span, capable of crossing obstacles, ideal for wide-range operations

- High load capacity, suitable for handling heavy materials

Cleanroom Electric Hoist

Features:

- High Cleanliness:

The cleanroom electric hoist features a fully enclosed design, equipped with advanced filtration systems and sealing components to prevent dust and particles from entering. This ensures a stable cleanroom environment and maintains product quality. - Low Failure Rate:

Designed to minimize the risk of malfunctions, it offers high operational reliability, a wide adjustment range, precise positioning, and fast lifting performance. - Anti-Static Design:

Constructed with anti-static materials and design elements to prevent dust attraction from static electricity, helping to maintain a clean environment. - Low Noise:

The drive system uses a high-efficiency motor and reducer, engineered for low noise to reduce disruption to workers. - High Efficiency and Energy Saving:

The electric drive system is both efficient and eco-friendly, producing no pollutants or excessive noise, aligning with environmental protection standards. - Compact Structure:

Featuring a stainless steel housing and bellows cover design, it offers a clean and sleek appearance, compact structure, and reliable performance.

Application

Stainless Steel Grab Overhead Crane

Features:

- Corrosion Resistance:

The food processing industry demands high standards of hygiene and safety for equipment. Stainless steel offers exceptional corrosion resistance, withstanding moisture, acidic substances, and other corrosive agents commonly found in food processing. This enables stainless steel grab bucket cranes to operate in wet, greasy, or chemically intensive environments for extended periods without significant corrosion, thus prolonging the equipment's service life. - Antibacterial Properties:

Stainless steel has excellent antibacterial performance, effectively preventing bacterial growth and reducing the risk of food contamination due to equipment. This is especially important in environments with strict hygiene requirements. - Easy to Clean:

With a smooth surface, stainless steel is easy to clean and disinfect, meeting the stringent cleanliness requirements of the food industry. All parts of the grab crane that come into contact with food can be quickly washed, ensuring no residue or sources of contamination remain. - High-Capacity Grabbing:

The stainless steel grab bucket crane is equipped with a grab mechanism that can collect large volumes of material in a single operation, making it ideal for handling bulk materials such as powders, granules, or liquids. - Adaptability to Harsh Environments:

In special food processing environments—such as cold storage rooms, high-humidity zones, or high-temperature areas—the crane's resistance to heat, humidity, and corrosion ensures stable and efficient performance under extreme conditions.

Application

Stainless Steel Grab Bucket Crane for Handling Distiller's Grains in a Brewery.