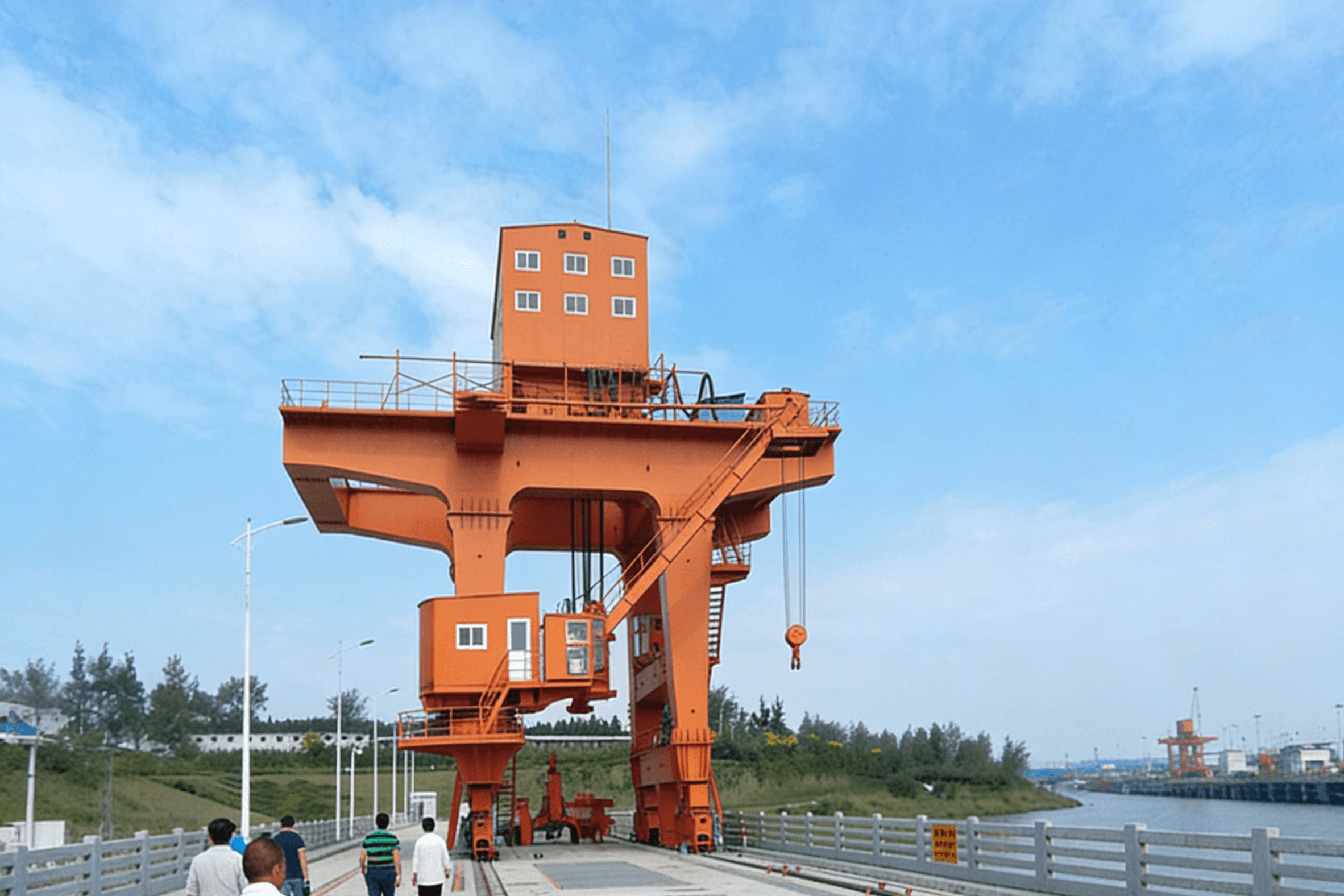

Spillway gate gantry crane: Dam-top Lifting for Gate Operation & Maintenance

A Spillway Gate Gantry Crane is a gantry-style crane installed on the crest of a hydroelectric dam. Typically configured as a unidirectional or bidirectional mobile unit, it consists of a main hoist trolley, a slewing hoist mechanism, a bridge travel mechanism, the gantry structure, an operator's cab, and various electrical equipment and safety protection devices.

Function of Spillway Gate Gantry Crane

Spillway gate gantry crane is primarily used for the operation (opening and closing) of intake maintenance gates and flood gates at the upper head of ship locks. It is also utilized for the heavy lifting of turbine components, as well as the installation and maintenance of sand-flushing gates and their fixed hoist systems. Furthermore, it transports relevant gates to the maintenance chamber for repair or storage, while the slewing crane is employed for lifting smaller equipment across the dam crest.

Key Features of Spillway Gate Gantry Cranes

- High Capacity & Precision: Designed with a high lifting capacity and height, low operating speeds, and a compact span—ideal for the demanding gate operations of large-scale hydropower stations.

- Unidirectional: The trolley is fixed; only the gantry travels along the dam.

- Bidirectional: The gantry moves along the dam axis (longitudinal) while the trolley moves in the direction of water flow (transverse).

- Expanded Reach: Equipped with a dual-slewing mechanism that significantly increases the crane’s overall working radius and coverage.

- Simplified Control: Engineered for easy operation and maintenance, supporting both local (on-site) and remote-control modes.

Spillway Gate Gantry Crane Specifications

Spillway Gate Gantry Crane Project Case

Baihetan Hydropower Station Crest Gantry Crane

The Baihetan Hydropower Station Spillway Gate Gantry Crane is a bidirectional cable-stayed gantry hoist with a lifting capacity of 10,000 kN/500 kN.

The main hook boasts a lifting capacity of 10,000 kN, currently the world’s highest single-hook capacity in the hydropower industry. It is primarily used for opening, closing, and transporting deep-hole accident gates.

The auxiliary slewing crane has a lifting capacity of 500 kN, primarily used for installing and maintaining the hydraulic hoist of the surface spillway gate.

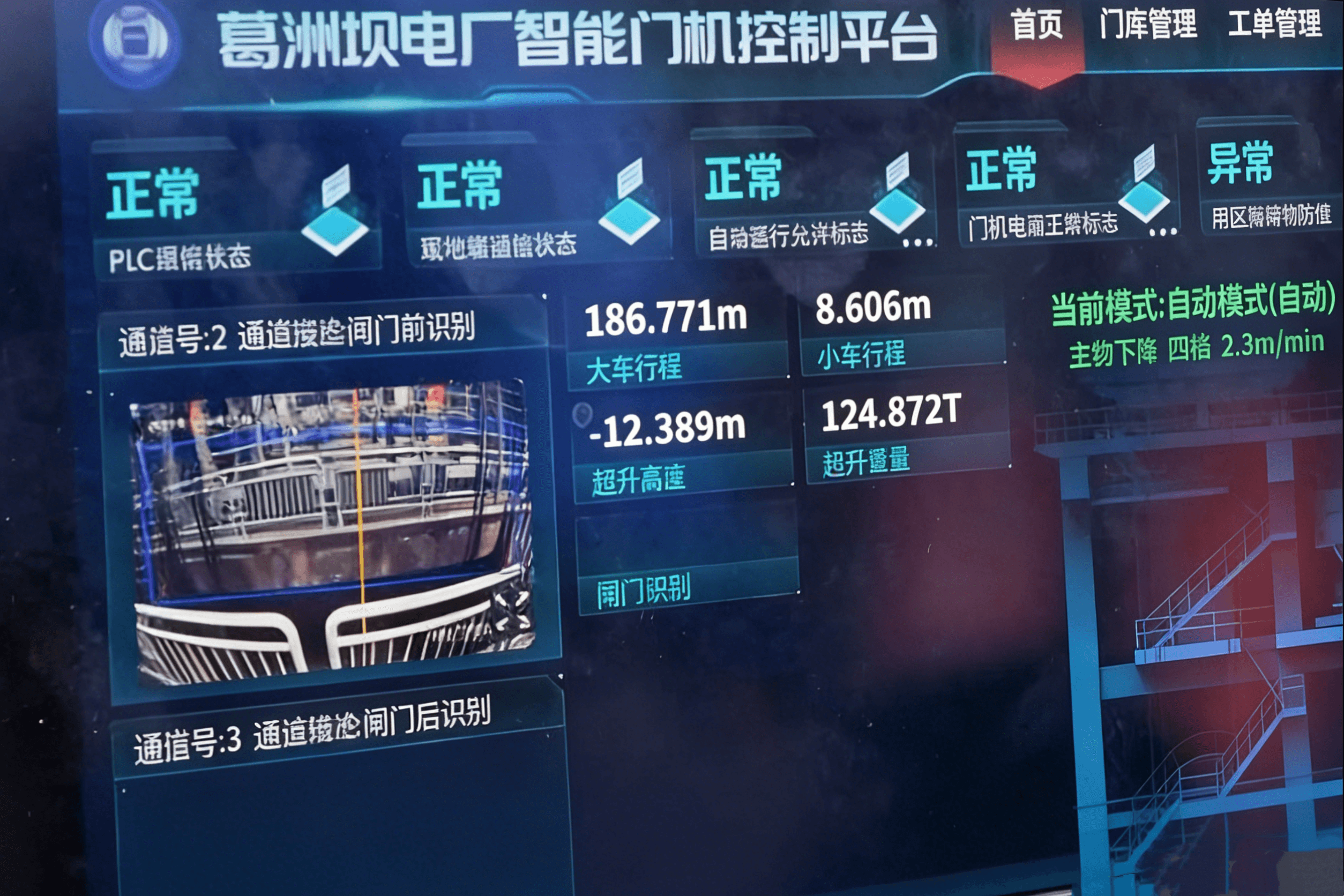

Gezhouba Hydropower Station Intelligent Gantry Crane

As the first large-scale hydropower project on the Yangtze River mainstream, Gezhouba Hydropower Station utilizes a massive spillway gate gantry crane standing 30 meters high with a 15-meter span. Weighing over 500 tons, this core equipment manages flat gate operations, playing a critical role in flood control, power supply, and dam safety.

Key Features

- Precision Positioning: Utilizing BeiDou (BDS), Laser, UWB, and linear encoding, the crane employs a “Coarse + Fine + Feedback + Redundant” flexible positioning architecture. This allows the system to perceive its exact coordinates, maintaining automated control accuracy within ±5mm.

- Smart Interconnection: An integrated crane-to-gate communication system leverages computer vision and RFID to achieve precise identification and automated detection of both the gates and gate slots.

- Lifecycle Health Management: With over 200 sensors monitoring structural stress and transmission faults, the system uses big data analytics to provide real-time equipment diagnostics and comprehensive lifecycle management.

- LiDAR Safety System: A built-in LiDAR anti-collision system scans the work zone for personnel and obstacles in real-time, triggering an immediate emergency stop if an anomaly is detected.

- High Efficiency: Gate response time has been reduced to under one minute, and the entire operation can be managed by a single operator.

Taocha Canal Headworks of the South-to-North Water Diversion Project

A 2×1500/300kN spillway gate gantry crane is installed atop the intake structure dam at the 176.6-meter elevation, serving both the diversion gate and power station inlet.

Key Features

- Advanced Hydraulic Drive: The trolley is powered by hydraulic cylinders, enabling effortless control and an ultra-wide range of stepless speed regulation (up to a 2000:1 ratio).

- High-Performance Dynamics: The hydraulic drive system is characterized by its lightweight and compact design, low movement inertia, and rapid response times, making it ideal for automated control.

- Intelligent Operation: By integrating electro-hydraulic combined control, the crane achieves a high degree of process automation and supports full remote-control operation.