-

INDUSTRIES

-

Precast Concrete Plant

-

Steel Industry

-

Paper Industry

-

Waste to Energy and Biomass Industry

-

Power Industry

-

Overhead Cranes for Automotive Production: Smart Solutions for Enhanced Efficiency

-

Port Machines Industry

-

Manufacturing Industry

-

Different Types of Container Cranes, Shipyard Cranes, Cargo Cranes Used in Port, Harbor and Quay

-

Overhead Cranes for Timber Lifting: Efficient and Safe Wood Handling

-

Overhead Cranes for the Aviation Industry: Streamlining Aircraft Assembly, Maintenance, and Repair

-

Overhead Cranes for Food and Beverages: Ideal for improving productivity and food safety

-

Overhead Cranes for Aerospace Industry: Key Role in Efficient Rocket Manufacturing and Launch

-

-

EQUIPMENT

-

Overhead Cranes

-

Single Girder Overhead Crane

-

Double Girder Overhead Crane

-

Underslung Cranes

-

Workstation Overhead Cranes

-

Low Headroom Overhead Cranes

-

Grab Bucket Overhead Crane

-

Electromagnetic Overhead Cranes with Lifting Magnet

-

Electromagnetic Overhead Cranes with Magnet Beam

-

Manual Overhead Cranes

-

Double Trolley Overhead Cranes

-

LDP Single Girder Overhead Cranes

-

- Eot Cranes

- Gantry Cranes

- Jib Cranes

- FEM Standard Crane & Hoist

- Hoist & Winch Trolley

-

Light Cranes

-

Portable Mobile Gantry Cranes

-

Adjustable Gantry Cranes

-

Aluminum Gantry Crane

-

Foldable Aluminum Gantry Crane

-

Monorail Overhead Cranes

-

Workstation Jib Cranes

-

Electric Hoists

-

Workstation Overhead Cranes

-

Freestanding Workstation Bridge Crane

-

Ceiling Mounted Workstation Bridge Crane

-

Manual Portable Gantry Crane

-

Multi-point Suspension Cranes

-

- Explosion Proof Cranes and Hoists

-

Special Cranes

-

35-65t Clamp Overhead Crane

-

Boat Hoists

-

Boat Jib Crane

-

Yacht Davit Crane

-

Rail Mounted Container Gantry Crane

-

Cleanroom Overhead Cranes

-

YZ Ladle Handling Cranes

-

LDY Metallurgical Single Girder Crane

-

Charging Cranes for Steel Production

-

Insulated Overhead Cranes

-

Gantry Crane for Subway and Metro Construction

-

Forging Crane

-

Quenching Overhead Crane

-

Baking Multifunctional Crane

-

- Port Cranes

- Electric Transfer Carts

-

Overhead Cranes

-

CRANE PARTS

- Crane Wheel Range

- Crane Spreader

- Crane Drives

-

Crane Electrical Equipment

-

Overload Limiter

-

Crane Cabin

-

Crane Power Supply System

-

Explosion Proof Crane Radio Remote Controls

-

Joystick Type Crane Radio Remote Controls

-

Pushbutton Type Crane Wireless Remote Controls

-

Single-pole Insulated Conductor Rails

-

Enclosed Conductor Rails

-

Seamless Conductor Rails

-

Copperhead Conductor Rails

-

Overhead Crane Cables

-

- Other Cranes Parts

\

- ABOUT US

- CONTACT US

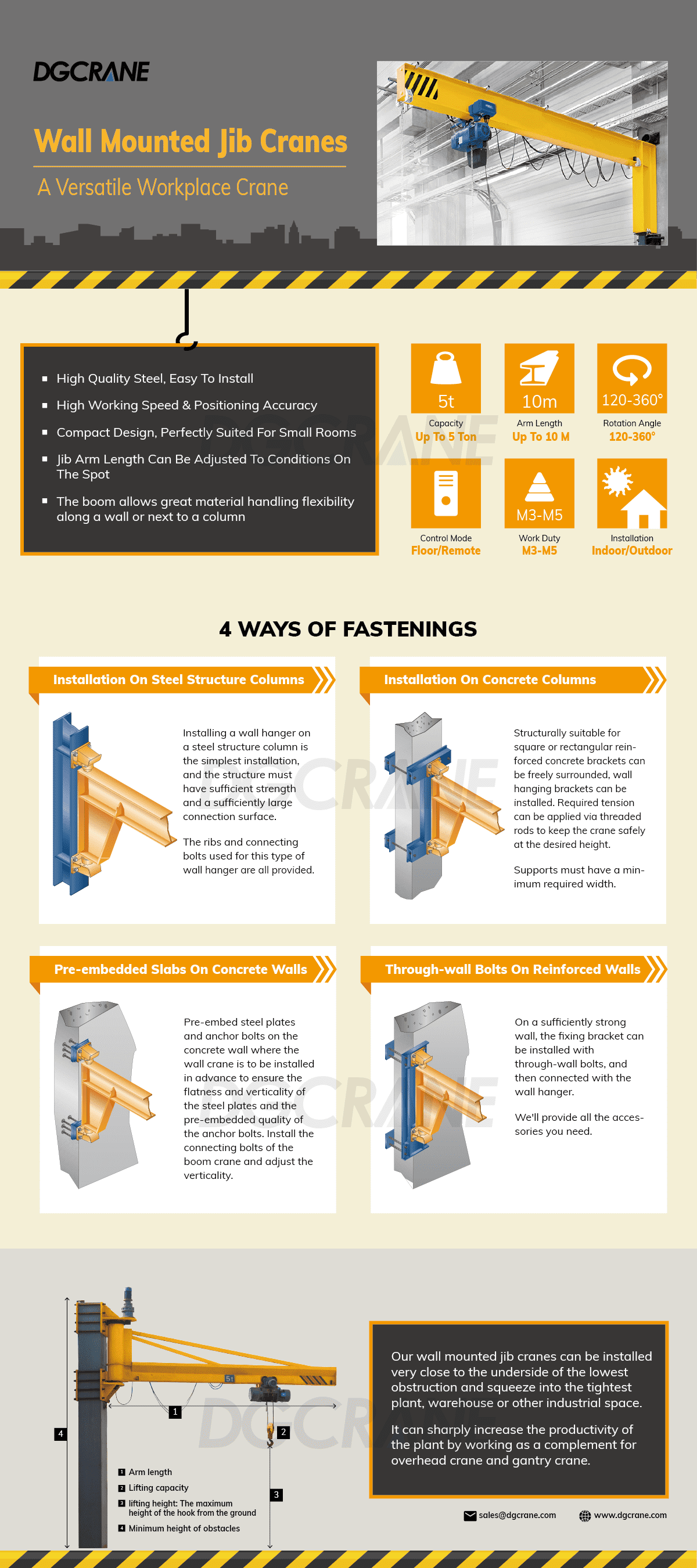

Wall-mounted jib cranes are an excellent choice for auxiliary overhead cranes, used inside the workshop, which have the characteristics of space saving, cost saving, and program flexibility. In this article, the installation steps and applicable working conditions for wall-mounted jib cranes are explained, and we hope you have some references to choose a wall-mounted jib crane.

Installation steps of wall-mounted jib crane

Wall-mounted jib cranes are designed to be mounted on a wall or a structural steel column. The installation process of a wall-mounted jib crane typically involves the following steps:

Step 1: Prepare the Installation Site

Before installing a wall-mounted jib crane, it is important to ensure that the installation site is level and has enough space for the crane to rotate freely. The installation site should also be clear of any obstacles that could interfere with the crane’s operation.

Step 2: Install the Wall Bracket

The first step in installing a wall-mounted jib crane is to install the wall bracket itself. The wall bracket should be mounted on a wall or a structural steel column that is strong enough to support the weight of the crane and the load it will be lifting. The bracket should also be perfectly vertical and aligned with the crane’s center of rotation.

Step 3: Mount the Jib Arm

Once the wall bracket is in place, the next step is to mount the jib arm on the bracket. The jib arm should be mounted at a height that allows it to clear any obstacles in the surrounding area. The mounting bolts should be tightened to the manufacturer’s specifications to ensure a secure connection.

Step 4: Install the Hoist and Trolley

The final step in installing a wall-mounted jib crane is to install the hoist and trolley. The hoist and trolley should be mounted on the jib arm and secured with bolts. The electrical wiring and controls should also be installed and tested before the crane is put into service.

Different wall-mounted cantilever crane installation methods

Column-mounted installation

In this method, the jib crane is mounted onto a free-standing column or post. This allows for greater flexibility in placement and can accommodate larger working areas.

Steel structure-mounted installation

For factories with large open spaces, a steel structure-mounted jib crane may be the best option. This method involves attaching the crane to a sturdy steel structure or frame, which provides a stable base while still allowing the crane to move freely.

Wall-mounted installation

This method involves mounting the jib crane directly onto a wall using heavy-duty bolts and brackets. The crane arm extends out perpendicular to the wall, allowing for easy access to loads along the length of the wall.

Zora Zhao

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

With 10+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

WhatsApp: +86 189 3735 0200

Email: zorazhao@dgcrane.com

Related Blogs

Subscribe to our newsletter

The latest DGCRANE price list, news, articles, and resources.

- Overhead Cranes

- Low Headroom Overhead Cranes

- Double Girder Overhead Crane

- Grab Bucket Overhead Crane

- Top Running Overhead Crane: Wide Application and Easy Maintenance

- Coker Cranes for Harsh Environments: High Temperature and Corrosion Resistant Design

- Overhead Cranes for Concrete Pile Precast Workshop: Versatile Solutions for Demanding Operations

- Single Girder Overhead Cranes

- Single Girder Eot Cranes

- Double Girder Eot Cranes

- Underslung Cranes

- Light Cranes

- Adjustable Gantry Cranes: Easy to Move, Safe, and Space-Efficient

- Foldable Aluminum Gantry Crane: Lightweight, Strong, and Portable

- Freestanding Workstation Bridge Crane: Lightweight, Modular and Adaptable Material Handling Solution

- Ceiling Mounted Workstation Bridge Crane: Ideal for Tight Spaces and Complex Layouts

- Multi-point Suspension Cranes: Suitable for Large-Span Industrial Workshop

- Manual Portable Gantry Crane: Cost-effective & Flexible for Light Lifting

- Workstation Overhead Cranes

- Monorail Overhead Cranes

- Workstation Jib Cranes

- Electric Hoists

- Gantry Cranes

- Shipyard Gantry Cranes: Specialized Lifting Solutions for Shipyard Operations

- Truss Gantry Cranes: Cost-Effective, Wind-Resistant, and Perfect for Large Spans

- FEM Double Girder Gantry Crane with Open Winch: European Performance, 20% Cost Saving

- Different Types of Small Portable Aluminium Gantry Cranes: Cost Effective

- Single Girder Gantry Cranes

- Double Girder Gantry Cranes

- Semi Gantry Cranes

- Casting Yard Gantry Cranes

- Container Gantry Cranes: RTG & RMG Solutions for Ports and Terminals

- Portable Mobile Gantry Cranes: Flexible, Movable and Space-Saving

- FEM Standard Crane & Hoist

- FEM Standard Overhead Cranes

- FEM Standard Gantry Cranes

- FEM Standard Jib Cranes

- FEM Standard Wire Rope Electric Hoists

- FEM Standard Electric Chain Hoists

- Hoist & Winch Trolley

- Low Headroom Wire Rope Electric Hoist: Compact Design for Efficient Lifting in Tight Spaces

- Electric Hoist for Molten Metal: High-Temperature, Safe Lifting for Metallurgical Environments

- Pneumatic (Air) Chain Hoists: Ideal for Explosion-Proof Environments

- Lever Hoists: Compact, Versatile Manual Lifting Tool

- Galvanizing & Pickling Electric Hoist for Harsh Environments

- 6 Double Girder Trolley Electric Hoists for Overhead Cranes: Custom Solutions for Every Lifting Need

- Manual Chain Hoists: Alloy Steel Construction for Smooth and Safe Lifting

- Electric Wire Rope Hoists

- Chain Hoists

- Crane Trolley

- Electric Winch

- Explosion Proof Cranes and Hoists

- Explosion Proof Single Girder Overhead Cranes: Safe Lifting Solution for Hazardous Environments

- Explosion Proof Wire Rope Electric Hoist: Upgrade Your Safe

- Explosion Proof Electric Chain Hoist of High Qualit

- Explosion Proof Manual Chain Hoist: Safety in Every Lift

- Explosion Proof Double Girder Overhead Crane: More Cost Effective

- Port Cranes

- Rubber Tyred Container Gantry Crane

- Ship To Shore Crane

- Container Straddle Carrier

- Harbour Portal Crane

- Shipyard Portal Cranes

- Container Gantry Cranes: RTG & RMG Solutions for Ports and Terminals

- Reliable Versatile Electric Transfer Carts

- AGV Transfer Carts

- Powerful Heavy Duty Coil Transfer Carts

- RGV Transfer Carts

- Powerful Pallet Transfer Carts

- Trackless Transfer Carts

- Reliable Heavy Duty Ladle Transfer Cars

- Superior Die Transfer Carts

- Rail Transfer Carts

CRANE PARTS

- Anode Carbon Block Stacking Overhead Crane for Aluminum Electrolysis Plants

- Spillway gate gantry crane: Dam-top Lifting for Gate Operation & Maintenance

- Automatic Rotary Feeding Overhead Crane: 330° Rotation & High Precision Positioning for Steelmaking

- Segment Handling System for Concrete Segments in Shield Tunnel Construction

- Subway Track Laying Gantry Crane for Tunnel Track Installation

- Intelligent Film Roll Handling Overhead Crane for Roll Changing, Stacking, and Warehousing

- Intelligent Loading Overhead Crane: Reduce Labor Costs and Improve Loading Efficiency

- Automated Steel Plate Handling Overhead Crane: Applications in Steel Storage & Warehouse Operations

- Straightener Roll Changing Overhead Crane: Automated Roll Handling for Straightening Machines

- High-Temperature Slab Handling Overhead Crane: Continuous Casting and Slab Yard Operations

- Automated Bulk Grab Overhead Crane: Efficient Ore, Coal, Sand, and Slag Handling

- Electrolytic Copper Cranes: Cathode and Anode Handling in Copper Electrolysis Lines

- Pot Tending Machine: Specialized Equipment for Electrolytic Aluminum Production

- Baking Multifunctional Crane: Furnace Tending Assembly for Efficient Carbon Roasting

- Heavy Duty Forging Cranes: Durable, High-Capacity Solutions for Forging

- Quenching Overhead Crane for Heat Treatment Plant: High-Temperature Insulated and Efficient Lifting Solution

- Gantry Crane for Subway and Metro Construction: Efficient Tunnel Debris Removal Solutions

- Insulated Overhead Cranes for Safe Non-Ferrous Metal Smelting

- Charging Cranes for Steel Production: Safe and Reliable Solutions for Efficient Material Handling

- Cleanroom Overhead Cranes: Reliable Solutions for Healthcare, Electronics, and GMP Workshops

- Rail Mounted Container Gantry Crane

- Special Cranes

- 35-65t Clamp Overhead Crane

- Boat Jib Crane

- Yacht Davit Crane

- Boat Hoists

INDUSTRIES

- Steel Industry

- Paper Industry

- Power Industry

- Overhead Cranes for Automotive Production: Smart Solutions for Enhanced Efficiency

- Port Machines Industry

- Manufacturing Industry

- Overhead Cranes for Timber Lifting: Efficient and Safe Wood Handling

- Overhead Cranes for the Aviation Industry: Streamlining Aircraft Assembly, Maintenance, and Repair

- Overhead Cranes for Food and Beverages: Ideal for improving productivity and food safety

- Overhead Cranes for Aerospace Industry: Key Role in Efficient Rocket Manufacturing and Launch

- Precast Concrete Plant

- Waste to Energy and Biomass Industry

- Different Types of Container Cranes, Shipyard Cranes, Cargo Cranes Used in Port, Harbor and Quay

COMPANY

- sales@dgcrane.com

- +86 373 387 6188

- +86 189 3735 0200

- Floor 30,Gongyuan INT'I Building, Jinsui Road, Xinxiang City, Henan Province, China