Top 4 Warehouse Crane Solutions for Small and Medium Warehouses

Table of Contents

As small and medium-sized warehouses increasingly prioritize efficiency and space utilization, selecting the right warehouse crane system has become essential for optimizing warehouse operations. This article highlights four mainstream crane solutions, each supported by real-world case studies, to illustrate their adaptability and advantages in various scenarios. Whether enhancing automation or improving handling flexibility, these solutions offer practical support for modern warehousing needs. The article serves as a valuable reference for decision-makers seeking efficient, safe, and intelligent equipment choices.

Bridge-type Stacker Crane

The bridge-type stacker crane is one of the earliest forms of automated stacking equipment. Structurally similar to an overhead crane, it is typically installed on fixed rails at the top of a warehouse and can span multiple aisles to perform storage and retrieval operations. It is well-suited for medium-height warehouses (around 12 meters) and is particularly ideal for scenarios with low inbound/outbound frequency, large-sized goods, or limited transport paths.

Features and Advantages

- Simple structure and easy operation; low maintenance requirements

- Can bypass obstacles for stacking and handling tasks

- Wide coverage – a single unit can serve multiple aisles

- Mounted on roof beams, saving valuable floor space

- Moderately priced – ideal for high-density storage with low handling frequency

- Flexible control options – compatible with manual, remote, or automated operation modes

Intelligent High-Rise Warehouse for Steel Coils

To enhance connectivity in steel industry logistics, an intelligent logistics system was built centered around an automated high-rise warehouse for oriented silicon steel coils. This smart warehouse serves as an automated storage facility specifically designed for steel coils.

Within a 1,000-square-meter space, steel coils are stacked in seven vertical layers using racking systems. A bridge-type stacker crane enables automated inbound, outbound, relocation, and storage of up to 4,000 coils. As a result, the client achieved a 350% increase in space utilization and 3.5 times the original storage capacity.

Key Features:

- Efficient and accurate warehouse operations through integrated WMS and WCS software systems

- Fully unmanned operation both overhead and on the ground, running 24/7

- Average handling cycle time of 4.5 minutes per coil

- 350% improvement in floor space utilization; 3.5× storage capacity increase

- Implementation of 5G wireless communication technology

- Automatic crane positioning with repeat accuracy of ±5mm

- Coil forks equipped with safety interlock mechanisms to ensure zero accidents during lifting

- Automated identification, gripping, and route planning via data collection, information processing, and command execution

- Redundant safety systems for precise positioning and accident prevention throughout the entire hoisting process

This intelligent high-rise warehouse provides comprehensive support for the circulation of finished steel products. It realizes vertical space optimization, automated storage and retrieval, and simplified operations—delivering a new level of smart logistics for the steel industry.

Storage and Retrieval Machine (SRM)

The aisle-type stacker crane is an automated storage and retrieval system (AS/RS) evolved from traditional forklifts and bridge-type stackers. It is primarily used for accessing goods in high-rack warehouses. By performing horizontal movement, vertical lifting, and fork extension actions, it enables precise transfer between storage locations and aisle entry points. It is particularly suited for automated warehouses where high space utilization is required and inbound/outbound frequency is moderate.

As one of the most widely used automation solutions in modern high-bay warehouses, the SRM is typically installed within rack aisles, operating along fixed rails for vertical and horizontal movement. With its lightweight structure, high precision, and fast response, it finds extensive application in industries such as e-commerce, pharmaceuticals, cold chain logistics, and manufacturing—especially where speed and accuracy are critical.

Electrical control options include manual, semi-automatic, stand-alone automatic, and full computer control. Structurally, SRMs can be categorized into single-mast and double-mast models.

Features and Advantages

- Ideal for narrow spaces, maximizing warehouse floor area

- High positioning accuracy, with a typical stopping error within ±1mm

- Multiple drive options ensure smooth operation and excellent speed control

- Lightweight design with strong resistance to bending and torsion

- Flexibly adaptable to various rack heights and load capacities; compatible with different unit loads (e.g., pallets, totes)

- High degree of automation; fully integrable with WMS/WCS systems for 24/7 continuous operation

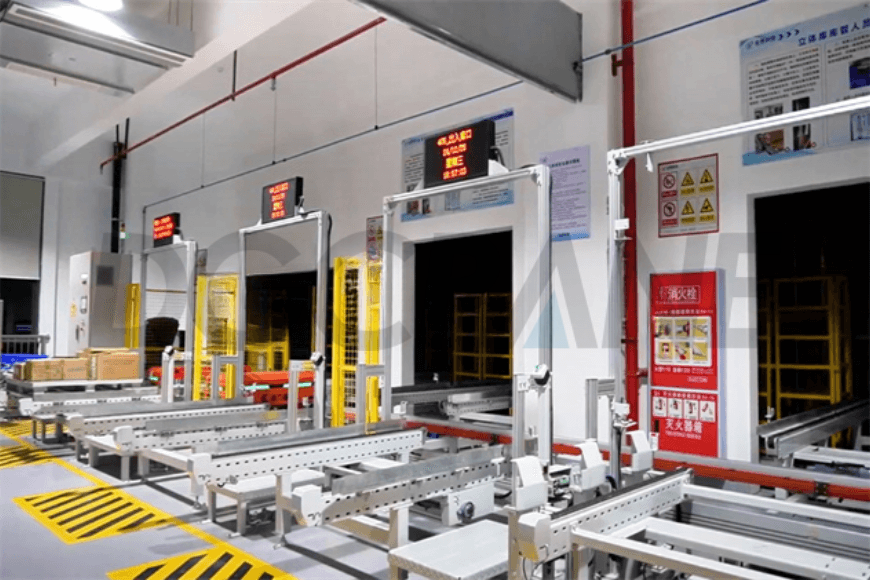

Smart Warehouse Project for an Electrical Connector Manufacturer

A high-tech enterprise specializing in the R&D and manufacturing of electrical connectors and electromechanical products, with thousands of precision components in its catalog, implemented a smart warehousing and logistics system to support the expansion of its intelligent factory. The goal was to establish a fully automated, closed-loop process from order receipt to warehouse operations—achieving high-density storage and efficient picking for nearly 10,000 SKUs of precision materials.

This project integrated a customized dual-system solution: a pallet-based stacker crane AS/RS combined with a bin-based four-directional shuttle AS/RS. The system includes pallet SRMs, 4-way bin shuttles (operating within a 51-level high-density racking system), RGVs, layer-changing/high-speed elevators, conveyors, warehouse racking, electrical control systems, and a WMS/WCS software platform.

Key Features:

- Built a 14-level pallet stacker crane AS/RS and a 22.3-meter-tall 4-way shuttle system, with a total storage capacity of over 18,700 locations

- Supports storage of nearly 9,700 types of precision components; space utilization improved by 10× compared to traditional systems

- Spans floors 1 through 4, enabling multi-floor, multi-production-line coordination

- 8 four-way shuttles operate in parallel, achieving 323 bins/hour picking efficiency

- Pallet SRM combined with RGVs delivers throughput of up to 70 pallets/hour

- Central control platform built on digital twin technology, offering real-time visual monitoring of warehouse operations

- WMS deeply integrated with ERP and MES systems for end-to-end production-logistics coordination

- Features a goods-to-person picking system, reducing labor costs by approximately 50% and improving warehouse turnover efficiency by 200%

- Peak processing capacity: 370 SKUs inbound/day, 872 SKUs outbound/day

Warehouse Overhead Crane

In small and medium-sized warehouses, overhead cranes primarily serve the purpose of efficient material handling and aerial transportation. By installing rails above the warehouse space, they allow for linear or area-wide hoisting without occupying floor space. This significantly improves space utilization, cargo flow speed, and loading/unloading efficiency.

“Garlic to the World” Unmanned Cold Storage Project

A company in Shandong built China's first unmanned cold storage intelligent warehousing system for agricultural use, located in the “Garlic to the World” industrial park. The project utilizes specialized 8+8 ton intelligent overhead cranes, achieving full automation, digitalization, and high-density storage—greatly enhancing operational efficiency and land-use effectiveness for cold storage facilities.

Advantages of Overhead Cranes in Garlic Storage:

- Long span, extended travel distance, and high lifting height

- Fast and stable operation with minimal fluctuation

- Supports manual (remote), semi-automatic, and fully automatic control modes

- Over 1,400 high-precision positioning points, with ±5mm accuracy at the lifting device

- Automated positioning, palletizing, outbound handling, and crate code recognition

- Features such as anti-sway electrical control, remote monitoring, real-time data syncing, backend database integration, and smart terminal compatibility

- 24/7 continuous operation, supporting multi-station concurrent tasks

Performance Outcomes in Garlic Warehousing:

- High-density intelligent storage for better space utilization

- Achieves vertical storage; warehouse area efficiency improved by nearly 10×

- Individual cold storage unit capacity reaches 60,000 tons, significantly enhancing land-use efficiency

- Fully automated workflow reducing operational costs

- Systematized and digitized processes improve task efficiency

- Labor costs reduced by 60%

- Precision positioning and anti-sway tech reduce hoisting errors and cargo damage

- Unmanned, round-the-clock operation

- Supports 24/7 operation, with continuous positioning, load optimization, and crate tracking

- Ensures high alignment between physical inventory and digital data for accurate real-time management

- Energy-efficient, green operations

- Centralized refrigeration and smart scheduling significantly reduce energy consumption

- System-wide optimization lowers idle time and energy waste

Warehouse Gantry Crane

In small and medium-sized warehouses or work areas, light-duty gantry cranes (also known as portable or mobile gantry cranes) are widely used. Unlike fixed-track systems, these cranes require no permanent installation and can be flexibly deployed as needed. They are particularly well-suited for small warehouses, temporary lifting tasks, and low-frequency operations.

With easy mobility and quick deployment, mobile gantry cranes respond efficiently to on-site material handling needs—without altering existing warehouse layouts or processes—helping businesses improve operational flexibility and resource utilization.

Advantages and Features

- Equipped with wheels for free movement—ideal for temporary stations or multi-zone use

- Simple structure with light lifting capacity—low investment and maintenance cost

- Perfect for supplemental or localized lifting where fixed cranes are impractical

- Easy to assemble, disassemble, and relocate—ideal for mobile or transitional work scenarios

5-Ton Mobile Gantry Crane for Glass Handling in Warehouse Operations

Mr. Mohamed from Senegal operates a business specializing in glass products. His typical operation involves unloading 3-ton glass crates from containers parked outside the warehouse and moving them indoors. However, two key challenges complicated the process:

- The warehouse door height is 5 meters, but the required lifting height also reaches 5 meters—making it difficult for traditional cranes to enter.

- The handling area spans both outdoor and indoor zones, requiring a crane that is highly mobile and can maneuver between them easily.

To meet these needs, DGCRANE custom-built a 5-ton electric mobile gantry crane for the client. The crane is equipped with omnidirectional wheels and an electric drive system, allowing smooth movement and turning. It uses an electric chain hoist for lifting, ensuring stable and efficient performance.

Key Feature – Electrically Adjustable Height:

- Lifting capacity: 5 tons

- Span: 3 meters

- Lifting height: 3.4 to 5.1 meters (electric adjustment)

- Overall height: Adjustable, minimum height of 4.5 meters allows easy passage through 5-meter-high doors

- Travel & cross-travel speed: 10 m/min to meet operational efficiency needs

The crane lifts the glass crates outdoors, lowers its height to pass through the warehouse entrance, then raises the load again for indoor stacking—achieving a complete outdoor-to-indoor handling process.

Compare & Choose: Selecting the Right Warehouse Crane for Your Warehouse

Choosing the right crane system is crucial for maximizing warehouse efficiency, space utilization, and operational flexibility. This section compares four major crane solutions—Bridge-type Stacker Crane, Unit Load Stacker Crane (SRM), Warehouse Overhead Crane, and Warehouse Gantry Crane—across key dimensions such as structure, application scenarios, automation potential, and cost.

| Comparison Dimension | Bridge-type Stacker Crane | Unit Load Stacker Crane (SRM) | Warehouse Overhead Crane | Warehouse Gantry Crane |

| Structural Features | Bridge structure spanning multiple aisles, trolley runs on bridge beam | Single-aisle track system, linear movement, aisle-dedicated device | Single-/double-girder, fixed rail, rectangular coverage | Mobile gantry structure with caster wheels, ground-level travel |

| Typical Applications | Multi-aisle, high-density automated warehouses | High-bay warehouses with large SKUs and frequent access | Medium to large warehouses, heavy lifting, frequent handling | Small warehouses, localized lifting, temporary operations |

| Space Utilization | Very high, supports cross-aisle operations | Very high, optimized aisle space | High, wide coverage but spatial constraints | Moderate, ground access required |

| Operational Efficiency | High, suitable for multi-point automated handling | High, high-frequency single-aisle operations | Medium, semi-automated or manual | Low to medium, suitable for infrequent or variable tasks |

| Automation Potential | Very high, commonly used in fully automated systems | Very high, deeply integrated with WMS/WCS | Medium, can be equipped with electric hoists or auto-positioning | Low to medium, limited remote or electric models |

| Flexibility | Medium, fixed layout, suited for large-scale system integration | Low, fixed aisle structure, limited flexibility | Medium, limited by track installation | High, highly mobile, easy to deploy or relocate |

| Investment & Maintenance | High, significant automation investment | High, high ROI but high initial cost | Medium, more cost-effective than traditional lifting systems | Low to medium, easy maintenance, mostly manual operation |

| Typical Use Cases | Automated multi-aisle warehouses, e-commerce cold chain logistics | SMT lines, high-end manufacturing storage | Raw material/finished goods handling, large object unloading | Workstation assembly, equipment installation, glass handling |

Each solution has distinct strengths:

- Bridge-type and SRM cranes excel in high-density, automated environments with intensive storage needs.

- Overhead cranes are better suited for medium to large warehouses requiring heavy-duty lifting.

- Gantry cranes provide unmatched mobility and flexibility for small-scale or temporary handling tasks.

If you need a high-density, multi-aisle, and complex-task automated storage system → Bridge-type Stacker Crane is recommended.

For efficient single-aisle operations in a traditional high-bay warehouse → SRM (Unit Load Stacker Crane) is the top choice.

If your warehouse has a regular layout, high lifting frequency, and heavy loads → Warehouse Overhead Crane is a suitable option.

For flexible deployment, multi-station coverage, and temporary handling needs → Warehouse Gantry Crane is the preferred solution.

By evaluating your warehouse’s operational needs, spatial constraints, budget, and desired automation level, you can identify the crane type that offers the best balance between performance and cost-effectiveness.

Conclusion

This page has provided a comprehensive comparison of four warehouse crane solutions tailored to the diverse needs of small and medium-sized warehouses. By examining structural features, application scenarios, efficiency, and cost, you now have a clear framework to evaluate which type best fits your operational priorities.

Whether you’re upgrading an existing facility or planning a new one, aligning the right crane system with your workflow can significantly enhance warehouse performance. Use this guide as a practical reference to support smarter investment decisions and build a more agile, efficient, and future-ready storage environment.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!