Top 10 Overhead Crane Manufacturers in USA: Reliable Suppliers for Your Projects

Table of Contents

The United States has a strong base of local overhead crane manufacturers, many with significant market strength. From this broad field, we have selected 10 leading companies based on their revenue and extent to which their business is focused on overhead cranes. This overview presents their profiles and main products, aiming to provide U.S. customers with helpful guidance when choosing an overhead crane manufacturer. (The order of presentation in this article does not imply any ranking or priority.)

Gorbel

Company Overview

Founded in 1977, Gorbel® started as a small company in Western NY and has now expanded to over 800 employees, with manufacturing locations in NY, AL, AZ, and Canada.

Main Products

- Workstation Cranes and Monorails

- Cleveland Tramrail Overhead Cranes

- I-Beam Jib Cranes

- Enclosed Track Jib Cranes

- Articulating Jib Cranes

- Gantry Cranes

Highlights

- The industry-leading manufacturer of material handling equipment, ergonomic solutions, and fall protection systems.

- Known for lightweight, modular, and easy-to-install designs, with strong advantages especially in workshop material handling and ergonomic lifting solutions.

- Focused on improving efficiency and safety, and recognized as an innovation leader in the field of enclosed track workstation cranes.

Mazzella Companies

Company Overview

Founded in the 1950s and headquartered in Cleveland, Ohio, Mazzella is one of the largest independent companies in the overhead lifting and rigging industry in North America, specializing in the manufacturing and distribution of a wide range of industrial, commercial, and specialty lifting products. Today, the company operates more than 45 branches across North America with a team of over 1,100 members.

Mazzella has strong design and manufacturing capabilities, enabling it to provide customized solutions ranging from light-duty, cost-effective cranes to large-capacity, high-duty-cycle cranes built with welded plate box girders. Its comprehensive product portfolio includes overhead cranes, gantry cranes, workstation cranes, jib cranes, monorails, and more.

With a professional engineering team and computer-aided design capabilities (SolidWorks), Mazzella offers tailor-made designs for various indoor cranes and track systems, with lifting capacities exceeding 150 tons.

All Mazzella products and operations strictly adhere to CMAA, NEC, OSHA, and ASME standards. Backed by extensive expertise in electrical and control engineering and the professional skills of AWS-certified welders (AWS D1.1 and D14.1), the company ensures the delivery of high-quality, safe, and reliable lifting solutions for its customers.

Main Products

- Custom Engineered Cranes & Hoists

- Patented Track Crane Systems

- Custom Engineered and Built-Up Hoists

- Overhead Cranes

- Gantry Cranes

- Workstation Cranes

- Jib Cranes

- Monorail Cranes

- Boat Transfer Lifts

- Davit Cranes

- Crane Components

Highlights

- Not only a manufacturer of overhead cranes, but also one of the largest suppliers of rigging and lifting tools in the United States.

- Well known for providing comprehensive lifting solutions, covering manufacturing, services, training, parts, and rigging, with extensive scale and capabilities.

Engineered Material Handling (EMH) Cranes

Company Overview

Founded in 1988 and headquartered in Valley City, Ohio, EMH has grown into a one-stop supplier offering a full range of overhead cranes and components. With a 125,000-square-foot manufacturing facility, EMH is able to produce products in the most efficient and cost-effective way.

EMH is ISO 9001:2015 certified and committed to a rigorous, ongoing quality control process. EMH is a proud member of the Material Handling Industry Association, the Crane Manufacturers Association of America, the National Precast Concrete Association, and the American Galvanizers Association, and a recipient of the prestigious Weatherhead 100 Award from Case Western Reserve University in Cleveland.

EMH utilizes advanced design and production processes to ensure crane quality meets customer specifications. With proprietary software, the company can deliver solutions quickly and accurately. Its manufacturing operations employ automated welding for efficient box girder production, and its well-stocked inventory of parts ensures smooth production flow.

Main Products

EMH designs, sells, and manufactures a complete line of overhead material handling equipment for loads from 35 lbs. to 300 tons.

- Overhead Cranes

- Jib Cranes

- Gantry Cranes

- Free Standing Bridge Crane System

- Aluminum Rail Workstation Cranes

- Crane Components

Highlights

- Equipped with a 125,000-square-foot manufacturing facility, enabling production in the most efficient and cost-effective manner.

- Proprietary design software allows for fast and accurate solution proposals, sometimes delivered within minutes of a customer inquiry.

- Utilizes automated welding for efficient box girder production, improving delivery speed.

American Crane & Equipment Corporation

Company Overview

American Crane is a women-owned business with over 50 years of history, headquartered in Douglassville, Pennsylvania.

The company's facilities total 226,000 square feet of manufacturing space with a lifting capacity of 150 tons. It houses one of the largest floor-mounted horizontal boring mills in the U.S. Northeast, as well as a 200-ton on-site load testing tower. The engineering team includes experts in mechanical, electrical, structural, and nuclear industries.

American Crane strictly adheres to nuclear quality standards such as 10 CFR 50 Appendix B and ASME NQA-1. The company also offers comprehensive services, including crane refurbishment, maintenance, OSHA inspections, load testing, and parts supply with over 40,000 items available.

Main Products

- Overhead Cranes

- Jib Cranes

- Gantry Cranes

- Air Chain Hoists

- Lever Hoists

- Hand Chain Hoists

- Integrated Trolley Hoists

- Crane & Hoist Parts

Highlights

Holds a unique advantage in the nuclear power and special engineering crane sectors, with products meeting stringent nuclear and military standards.

Tri-State Overhead Crane

Company Overview

Tri-State Overhead Crane specializes in the design, manufacturing, and installation of overhead cranes and hoists. Headquartered in St. Louis, Missouri, the company operates a 60,000-square-foot facility that includes large crane manufacturing area, machine shop, and parts warehouse.

Since its founding in 1959, Tri-State Overhead Crane has been a leading supplier of overhead cranes and electric hoists in the Midwest. Throughout its development, the company has worked closely with industry-leading manufacturers such as CM, Demag, Harrington, and Gorbel. As a platinum distributor for these brands, Tri-State provides customers with stocked replacement parts, factory-authorized repairs, and reseller discounts.

Over the years, Tri-State has expanded, opening branches in other states. With sales experts covering most of the U.S., the company can meet directly with customers to develop material handling improvement solutions for their facilities, helping to boost productivity and reduce manufacturing costs.

Main Products

- Overhead Cranes

- Hoists

- Jib Cranes

- Gantry Cranes

- Crane Control/Modernization

- Lifting Devices

Highlights

- Combines manufacturing and distribution capabilities, serving as an authorized distributor for brands such as CM, Demag, Gorbel, and Harrington.

- Maintains a dense network of service locations in the U.S. Midwest and Southeast, ensuring fast response times.

- Features an experienced sales team, comprehensive turnkey systems, ample inventory, and highly competitive pricing.

Columbus McKinnon

Company Overview

Founded in 1875 and headquartered in Charlotte, North Carolina, Columbus McKinnon Corporation (CMCO) has a history of 150 years. The company began with the manufacturing of chains and hoists and has since grown into a global leader in intelligent material handling and motion control solutions.

CMCO's products include electric hoists, crane components, precision conveyor systems, rigging tools, light-duty track workstations, as well as digital power and motion control systems, serving industries such as manufacturing, energy, logistics, and construction. The company is committed to improving efficiency and safety through innovative technologies and driving the digitalization and automation of industrial material handling.

CMCO operates in more than 50 countries worldwide, employing over 3,000 people. It owns 19 international brands, including CM, Yale, STAHL CraneSystems, Magnetek, Coffing, Dorner, and Duff-Norton. Its global operations encompass offices and manufacturing facilities across North America, Latin America, Europe, the Middle East, Africa, Asia, and Oceania.

Main Products

- Overhead Cranes

- Workstation Crane Systems

- Hoists

- Jib Cranes

- Gantry Cranes

- Lifting Tables

- Crane Components

- Rigging Equipment

- Precision Conveyors

Highlights

- A global brand with products exported worldwide.

- Owns numerous sub-brands, offering a comprehensive product line.

- Electric hoists and crane components hold significant market share internationally.

Overhead Crane & Conveyor Service

Company Overview

Overhead Crane & Conveyor Service Corp., headquartered in Dickson, Tennessee, provides customized solutions ranging from ½ ton hoists to 50 ton box girder cranes. Its services cover the full lifecycle, including runway design, manufacturing and installation, maintenance and inspection, as well as on-site operator training.

The company serves clients across industries such as manufacturing, injection molding and stamping plants, metal buildings, and concrete facilities. It has also supplied hundreds of cranes for the water treatment sector, widely used in the installation and maintenance of pump stations in both wastewater and potable water projects.

Government and military clients are another key market, including aircraft and helicopter maintenance hangars, military vehicle maintenance areas, pump stations, and NASA projects. With flexible customization capabilities and extensive industry experience, Overhead Crane & Conveyor Service delivers reliable crane solutions to both industrial and public-sector clients.

Main Products

- Overhead Cranes

- Jib cranes

- Hoists

- Below the Hook Lifting Devices

- Conveyors

Highlights

- Serves government and defense industry clients, including general aircraft, helicopter, and fighter jet maintenance hangars, pump stations, sludge treatment plants, vehicle garages, and more.

- Military-friendly company, supporting a wide range of missions for the U.S. Army, Army National Guard, Air National Guard, Corps of Engineers, Air Force, and NASA.

Dearborn Overhead Crane

Company Overview

Dearborn Overhead Crane is a family-owned business based in Mishawaka, Indiana, with over 60 years of experience in the crane industry. The company specializes in the design, manufacturing, installation, and maintenance of a wide range of lifting equipment, including overhead cranes, gantry cranes, jib cranes, and hoists, with capacities ranging from 100 pounds to 100 tons to meet diverse industrial needs.

As an ISO 9001-certified manufacturer, Dearborn Overhead Crane provides end-to-end services from design to commissioning, ensuring projects meet high standards of quality and safety.

The company also offers emergency support, preventive maintenance, operator training, and OSHA-compliant inspections to ensure the efficient and safe operation of crane systems. Its clients span industries such as manufacturing, construction, automotive, and steel, making Dearborn a trusted partner for reliable, customized lifting solutions.

Main Products

- Overhead Cranes

- Gantry Cranes

- Jib Cranes

- Crane Kits

- Crane Accessories

- Hoists

Highlights

Dearborn Overhead Crane’s strength is their experience. Basically, everyone has the same motors, steel, and bearings, but they have over sixty years of expertise that helps clients get the right motors and the right bearings. No more, no less.

Reading Crane & Engineering

Company Overview

Reading Crane & Engineering, located in Reading, Pennsylvania, was founded in 1905 and has over 100 years of experience in the crane industry. The company specializes in the design, manufacturing, installation, and servicing of customized overhead cranes and hoist systems, including top-running and under-running, single-girder and double-girder configurations, tailored to meet the specific needs of various industrial clients.

Reading Crane provides 24/7 emergency repair and engineering design services, supported by a team of structural, mechanical, electrical, and civil engineers to address both on-site and office-based technical challenges.

The company serves clients across industries such as ports, shipyards, heavy manufacturing, energy, transportation, metallurgy, pulp and paper, and power generation, earning a reputation for high-quality products and professional services.

Main Products

- Automated Crane Systems

- Overhead Cranes

- Hoists

- Runway Systems & Electrification

- Below Hook

- Electrical Controls

Highlights

With over 100 years of history, a highly experienced overhead crane manufacturer.

DeShazo Crane Company, LLC

Company Overview

DeShazo Crane Company, LLC is one of the leading crane manufacturers in the United States. Founded in 1972 and headquartered in Bessemer, Alabama, the company also operates production facilities in Alabaster, Alabama, and Winchester, Kentucky. DeShazo design, manufacture and install overhead cranes from light industrial to CMAA class “F” mill duty service, and every crane that comes out of the shop is 100% custom-built.

The company has over 300,000 square feet of manufacturing space and more than 500 employees. Engineering design utilizes CAD/CAM technology and 3D modeling to ensure precision and quality. To date, over 25,000 DeShazo cranes are in operation worldwide, serving industries across North America, South America, the Middle East, and Asia.

DeShazo is ISO 9001:2015 certified and strictly adheres to OSHA and CMAA standards to ensure the quality and safety of its products and services.

Main Products

- Double Girder Cranes

- Single Girder Cranes

- Built-Up Trolley Hoists

- Runway Systems

- Crane Components

- Misc. Equipment(such as radio controls, under-the-hook attachments, monorail systems and jib cranes)

DGCRANE: Trusted Overhead Crane Supplier and Global Exporter from China

Company Overview

DGCRANE is based in Changyuan County, Henan Province—the largest crane manufacturing hub in China. With ISO 9001, CE, and SGS certifications, we specialize in crane design and production, ensuring our products meet international standards.

We provide tailored overhead crane solutions for ports, manufacturing, waste handling, paper making, metal smelting, food processing, and many other industries. Our cranes have been exported to over 100+ countries, including Russia, Australia, Canada, and America. Renowned companies, such as Italy IMF Group(the biggest complete set of foundry equipment supplier in the world), have also chosen DGCRANE as their partner.

Committed to becoming a recognized international brand in the overhead crane industry, DGCRANE continues to deliver reliable, innovative, and cost-effective lifting solutions worldwide.

Main Products

- Overhead Cranes

- Gantry Cranes

- Jib Cranes

- Hoists

- Crane Components

- Transfer Carts

Why Choose DGCRANE

Competitive Price Advantage

Compared with overhead crane manufacturers in USA, DGCRANE offers lower prices for the same configuration and lifting capacity. Even after accounting for shipping and other fees, the overall cost remains highly competitive, allowing customers to get high-quality cranes while staying within a more reasonable budget.

Wide Range & Customization

From overhead cranes, gantry cranes, electric hoists, and crane parts, DGCRANE provides a complete product line. Each product can be tailored to meet specific working conditions, including capacity, span, lifting height, voltage, and even special requirements such as explosion-proof or high-temperature resistance.

Certified Quality You Can Trust

The products are manufactured under strict quality control systems and carry international certifications such as ISO, CE, and SGS.

Extensive Export & Professional Support

DGCRANE has exported overhead cranes to over 100 countries, gaining rich experience in logistics and after-sales service. Based on your needs, we can dispatch professional engineers to provide design, installation, and maintenance support, ensuring service quality comparable to local providers.

DGCRANE Cases in the USA

13 Sets of Overhead Cranes with Supporting Steel Structures Delivered to the USA in 20 Days

We completed the fabrication of 13 overhead cranes and steel structures within 4 weeks according to the customer's requirements, and successfully loaded and shipped them in the 5th week, keeping the transportation time within 20 days.

The goods were delivered on schedule. When the containers arrived at the customer's facility, our engineers in Mexico had just finished their on-site work and arrived at the customer's site on time. The installation of all 13 overhead cranes was completed within two and a half months.

1 Ton Overhead Crane Exported to the USA

The customer planned to add a new overhead crane in their existing workshop for lifting machinery spare parts. Therefore, in the early stage of the project, it was essential to clarify key parameters, including span, maximum lifting capacity, and runway length, especially taking into account the available space in the workshop.

With the customer's active cooperation, after approximately seven days of multiple rounds of communication and confirmation, the specifications for the overhead crane were finalized.

- Lifting capacity: 1t

- Lifting height: 5.1m

- Span length: 4.88m

- Quantity: 3 sets

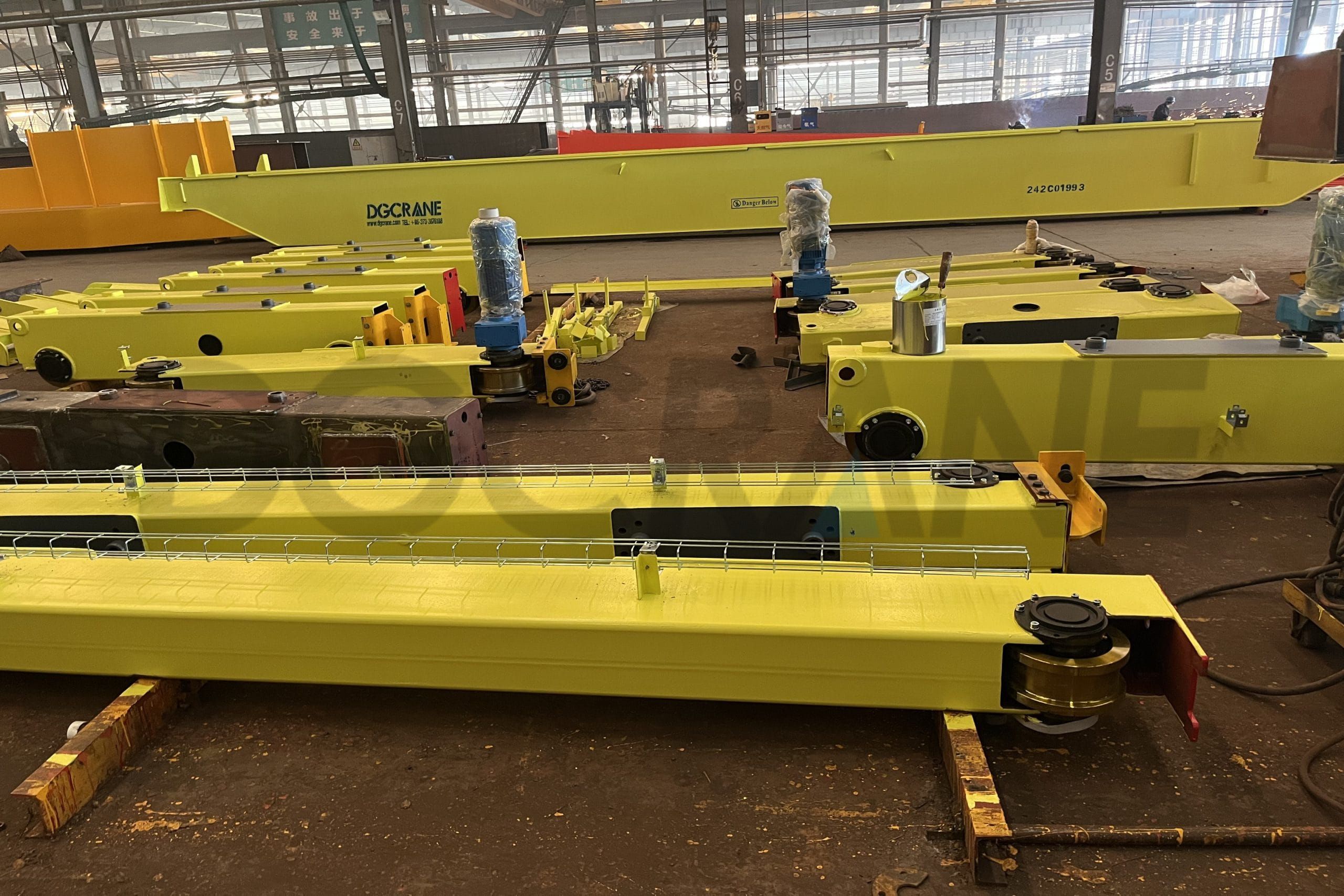

2 End Beams and 1 Trolley with Hoist Delivered to the USA

We completed the production of 2 sets of end beams and 1 trolley with hoist for our American client. The customer is a crane manufacturer in the United States, responsible for producing the main beam of a double girder overhead crane, while sourcing the supporting parts such as end beams and trolley systems from us.

We not only supply complete overhead cranes but also provide a full range of related crane components. Whether you need end beams, trolleys with hoists, or other spare parts, we are ready to support your projects with reliable solutions.

Conclusion

Local suppliers offer more convenient communication and faster response, and can be prioritized if they meet the project requirements. For buyers seeking reliable quality, strong customization, and excellent cost-performance, DGCRANE is a recommended choice.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!