Overhead Cranes in Kuwait: Industry Applications and Trusted Suppliers

Table of Contents

Kuwait major industries include oil and gas, manufacturing, construction, and food and agricultural production, all of which maintain a steady demand for overhead cranes. At present, the Kuwaiti overhead crane market features both local suppliers and international ones. This article introduces the applications of overhead cranes in Kuwait key industries and provides an overview of the main suppliers in the market.

Main Industry and Overhead Crane Solutions in Kuwait

Oil and Gas

Kuwait is an important oil producer, and the market size of its oil and gas industry is expected to reach USD 39.1 billion by 2030. The country's oil and gas sector covers upstream exploration and extraction, midstream transportation and storage, as well as downstream refining and petrochemical processing. Due to the large scale of facilities and the heavy weight of equipment, the industry maintains a steady demand for heavy-duty handling and lifting equipment. Common types of overhead cranes used in the oil and gas industry include coker overhead cranes and explosion-proof overhead cranes.

Coker Overhead Cranes

The coker crane is used in refineries and petrochemical plants to lift newly produced, high-temperature coke from the coke oven and allow it to cool. Approximately 24 hours later, once the coke has cooled and excess moisture has been removed, the crane transports it to crushers, hoppers, or conveyor systems.

Coker overhead cranes operate in harsh environments filled with moisture, corrosive fumes, and abrasive dust, requiring strong corrosion resistance. Additionally, these cranes must operate efficiently around the clock to ensure seamless handling of coke and prevent production interruptions.

Coker overhead cranes can be equipped with an intelligent unmanned management system, enabling fully automated operations such as precise grabbing, yard transfer, unloading, and loading. This system allows for accurate remote control, preventing operators from being exposed to high temperatures, high humidity, and toxic environments.

Explosion Proof Overhead Cranes

Explosion-proof overhead cranes are used in production areas containing flammable and explosive gases for equipment installation and maintenance.

In the oil refining process, explosion-proof overhead cranes are widely used in hydrocracking units, catalytic reforming units, and storage tank areas. These areas often contain flammable gases such as methane and hydrogen sulfide. The cranes are equipped with explosion-proof motors, control boxes, and other components, featuring strict isolation and sealing measures to prevent electrical sparks from igniting gases.

In the liquefied natural gas (LNG) sector, explosion-proof overhead cranes are mainly used in LNG plants and compressor stations. Given the high concentration of methane and low-temperature environment, the cranes must meet both explosion-proof and anti-static requirements to ensure safe maintenance of compressors, cryogenic pumps, and other critical equipment.

Building Materials Manufacturing

The “Kuwait 2035 Vision” outlines a series of large-scale projects, including new city construction, highways, and residential developments. By 2030, Kuwait construction market is expected to reach USD 20.2 billion. The steady progress of these projects has driven strong demand for construction materials such as cement, steel, precast components, glass, and stone. In the construction materials industry, commonly used overhead cranes include single and double girder overhead cranes, as well as grab overhead cranes.

Single and Double Girder Overhead Cranes

Overhead cranes are widely used in the building materials industry. In glass manufacturing, they are employed to handle finished glass panels, ensuring smooth movement and minimizing damage. In cement production lines, overhead cranes are used for lifting clinker, mill equipment, and finished cement products. In the production of precast concrete components, overhead cranes are utilized to transport cast components and molds, enabling efficient transfer of materials from the production line to the storage or loading area.

Grab Bucket Overhead Cranes

Grab overhead cranes are mainly used in the building materials industry for handling bulk materials such as sand and gravel. In cement plants, they are employed to transport bulk materials like limestone, clay, and slag from the stockyard to crushers, mills, or storage areas. In glass production, grab overhead cranes are used for handling raw materials such as silica sand, soda ash, and limestone.

Food Industry

Kuwait food manufacturing market is expected to reach approximately USD 328 million by 2026, with a primary focus on sectors such as flour, dairy products, biscuits, and beverages.

Cleanroom Overhead Cranes

In the food industry, cleanroom overhead cranes are primarily used. They are designed with easily cleanable materials and structures to effectively inhibit the growth of bacteria and other microorganisms. Key components of the equipment are often made of stainless steel to reduce wear, prevent debris from falling, and enhance corrosion resistance. The main beam is equipped with an anti-static system to prevent static buildup, which could attract dust or hair, further ensuring food-grade cleanliness. The crane's exterior is typically coated with inorganic anti-corrosion layers or polyurethane protective paint, providing resistance to chemical corrosion, high temperatures, and humidity, thereby maintaining long-term, stable protection.

Local Overhead Crane Suppliers in Kuwait

National Equipment

- Company Overview: National Equipment was established in 1994 as a manufacturer and provider of high-quality overhead cranes and jib cranes in Kuwait. The company’s cranes are equipped with motors and hoists imported from Omis in Italy.

- Product: overhead cranes and jib cranes.

- Proven Track Record: Their cranes have been approved and installed in renowned organizations such as Halliburton, Ministry of Defense, and Kuwait National Guard.

STAHL Kuwait

- Company Overview: STAHL Kuwait is the partner of STAHL Crane Systems GmbH, providing overhead cranes, hoists, crane components, and explosion-proof cranes in Kuwait.

- Product: Overhead cranes, wire rope hoists, chain hoists, crane components, wheel blocks, working stations, jib cranes, electrical components, OEM spare parts, radio controls, electronic operation monitoring.

Kuwait Technical Company

- Company Overview: Kuwait Technical Company provides overhead cranes and jib cranes, and offers services including crane, hoist, troubleshooting, repair, and general maintenance.

- Product: single girder overhead crane, double girder overhead cranes, Jib cranes, under slung cranes and special cranes.

Chinese Overhead Crane Suppliers Rising Popularity in Kuwait

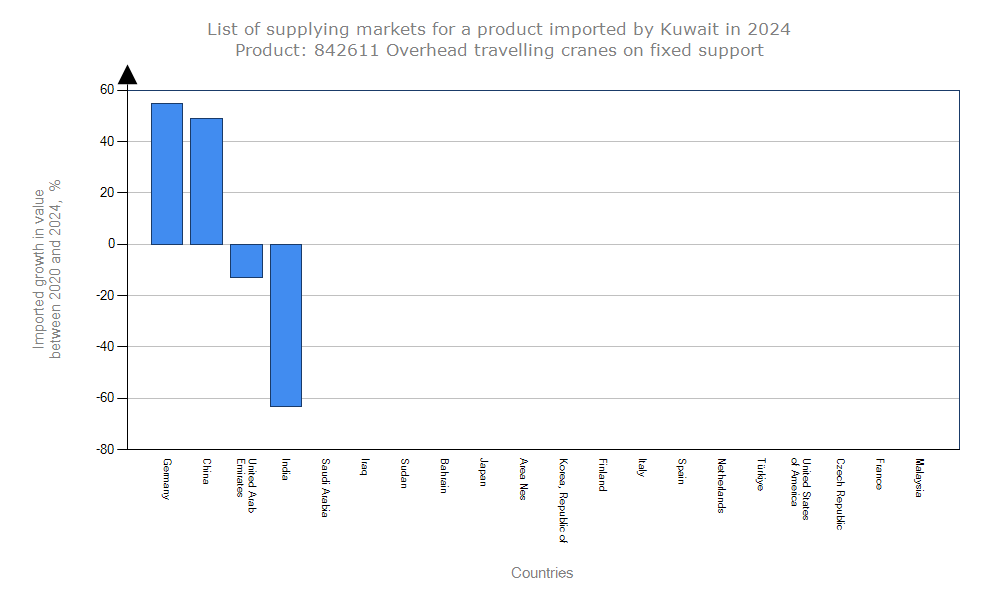

In Kuwait, an increasing number of customers are turning to Chinese overhead crane suppliers. According to ITC Trade Map data, between 2020 and 2024, Kuwait ranked second in terms of the growth in overhead crane imports from China.

Chinese suppliers are highly favored in Kuwait for several key reasons:

- High cost-performance: China is a major crane manufacturing country with a mature production system and complete supply chain. High production efficiency allows Chinese overhead cranes to be priced 20%–40% lower than products from Europe, Japan, and other developed countries with comparable quality and specifications, effectively reducing procurement costs for Kuwaiti customers.

- Wide product range: Chinese overhead cranes are available in a broad spectrum, from 1 to 800 tons, including customized solutions for special conditions such as explosion-proof, high-temperature resistant, and intelligent unmanned operation. Whether for construction, metallurgy, logistics, or port projects, there is a solution that matches the specific requirements.

- Reliable delivery and after-sales service: As a major exporter, Chinese crane suppliers have extensive experience in international shipping and customs procedures, ensuring timely and accurate delivery to Kuwait. They also possess rich experience in overseas installation and after-sales service, providing fast response and problem-solving for customers.

Compared with local suppliers in Kuwait, Chinese overhead crane suppliers are larger in scale and offer a wider variety of products, capable of meeting the diverse needs of different projects. Compared with European and American suppliers, Chinese suppliers provide competitive pricing without compromising core performance. Therefore, for Kuwaiti customers seeking quality, cost-effectiveness, and flexible customization, Chinese overhead crane suppliers are an ideal choice.

DGCRANE: A Chinese Overhead Crane Supplier for Kuwait

DGCRANE is a professional overhead crane supplier and exporter based in Henan, China. Since its establishment, the company has been dedicated to providing high-quality lifting solutions to customers worldwide, integrating design, manufacturing, sales, and installation. Over the years, DGCRANE products have been exported to more than 120 countries and regions, including Kuwait, Saudi Arabia, the UAE, the United States, and Russia.

With extensive international project experience and a well-established export system, DGCRANE is familiar with the technical standards and operational environments of the Middle East, enabling the company to provide customized crane solutions that meet local requirements. Its main products include overhead cranes, gantry cranes, jib cranes, and electric hoists, widely used in the oil and gas industry, manufacturing, construction, food industry, and energy sector.

In Kuwait, DGCRANE has successfully delivered multiple customized overhead cranes, fully accounting for local climatic conditions such as high temperatures and sandstorms. The company provides full technical support from structural design to crane installation, ensuring stable operation and long-term reliability.

Through continuous technological improvements, strict quality control, and comprehensive after-sales service, DGCRANE has earned the trust of customers in Kuwait and the broader Middle East market, establishing itself as a reliable partner for industrial lifting equipment.

DGCRANE Cases in Kuwait

5T Single Girder Overhead Cranes (Without Main Beams) Exported to Kuwait

- Product: Low headroom single girder overhead cranes (without main beams)

- Capacity: 5t

- Span: 15m&12m

- Lifting height: 6m

- Lifting speed: 8m/min

- Power: 415V/50Hz/3ph

Customer Requirements

The customer required two overhead cranes but preferred not to purchase the main beams from us in order to reduce the overall project cost and make use of local fabrication resources.

In addition, the workshop height was limited, and the customer wanted to maximize the available lifting height.

Our Customized Solution

To meet the customer’s specific needs, we supplied two sets of single girder overhead cranes excluding the main beams, along with the complete conductor rail system.

Given the limited workshop height, we designed the cranes in a low headroom configuration using low headroom electric hoists to achieve the maximum possible lifting height.

Based on the workshop layout and operational requirements, our team completed the technical design, fabrication of end beams and electrical systems, and provided CAD drawings of the main beams for local production in Kuwait.

Single Girder Overhead Crane Exported to Kuwait

- Capacity: 5t

- Lifting height: 5.5m

- Span: 25.5m

- Hoist lifting speed: 5/0.8m/min

- Hoist traveling speed: 2-20m/min

- Crane traveling speed: 3-30m/min

- Control method: wireless remote control

Customer Requirements

The customer wanted to achieve the maximum lifting height within the existing workshop height.

Our Customized Solution

To meet the customer’s specific needs, we precisely calculated and customized the structure and dimensions of the crane’s main beam. While ensuring safety and stable operation, we optimized the main beam design and used a more space-saving electric hoist, enabling the crane to achieve the customer’s desired maximum lifting height within the existing workshop height.

50t+20t Double Girder Gantry Crane for Kuwaiti Hydropower Station

- Lifting capacity: 50t+20t

- Span: 13m

- Lifting height: 15m+15m

- Duty group: A2

- Power supply: 415v 50hz 3ph

- Control model: Wireless remote control + Cab control

Project Overview

The crane was delivered to a Hydropower Station in Kuwait, which is a key government project with strict requirements for crane quality. Throughout the collaboration, our client provided us with great support and trust, ensuring the project proceeded very smoothly.

Transportation & Packaging

Considering the large size of the crane components, we opted for bulk cargo transportation to ensure smooth delivery. Our factory carefully packaged all the parts to ensure they were well-protected during transit.

Conclusion

If your overhead crane needs are relatively basic and you prioritize fast service response, local suppliers can be a good choice. However, if you value a wider product range, higher quality, and better cost-performance, Chinese suppliers have a clear advantage. Among them, DGCRANE, as a professional Chinese crane supplier, not only offers a full range of high-performance overhead crane solutions but also leverages years of overseas project experience, having successfully delivered multiple large-scale industrial projects in Kuwait. Whether it's upgrading industrial production lines or ensuring efficient warehouse and logistics operations, DGCRANE provides reliable and efficient crane solutions, helping Kuwaiti customers improve operational efficiency and achieve sustainable development.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!