Overhead and Gantry Cranes in the Philippines: High Demand and Reliance on Imports

Table of Contents

The Philippine market for overhead and gantry cranes is characterized by notable demand alongside limited domestic production capacity. While there is some local manufacturing activity, it remains insufficient to cover the country's requirements in sectors such as automotive, food processing, steel, and renewable energy. As a result, the Philippines continues to rely significantly on imports to support its industrial lifting needs.

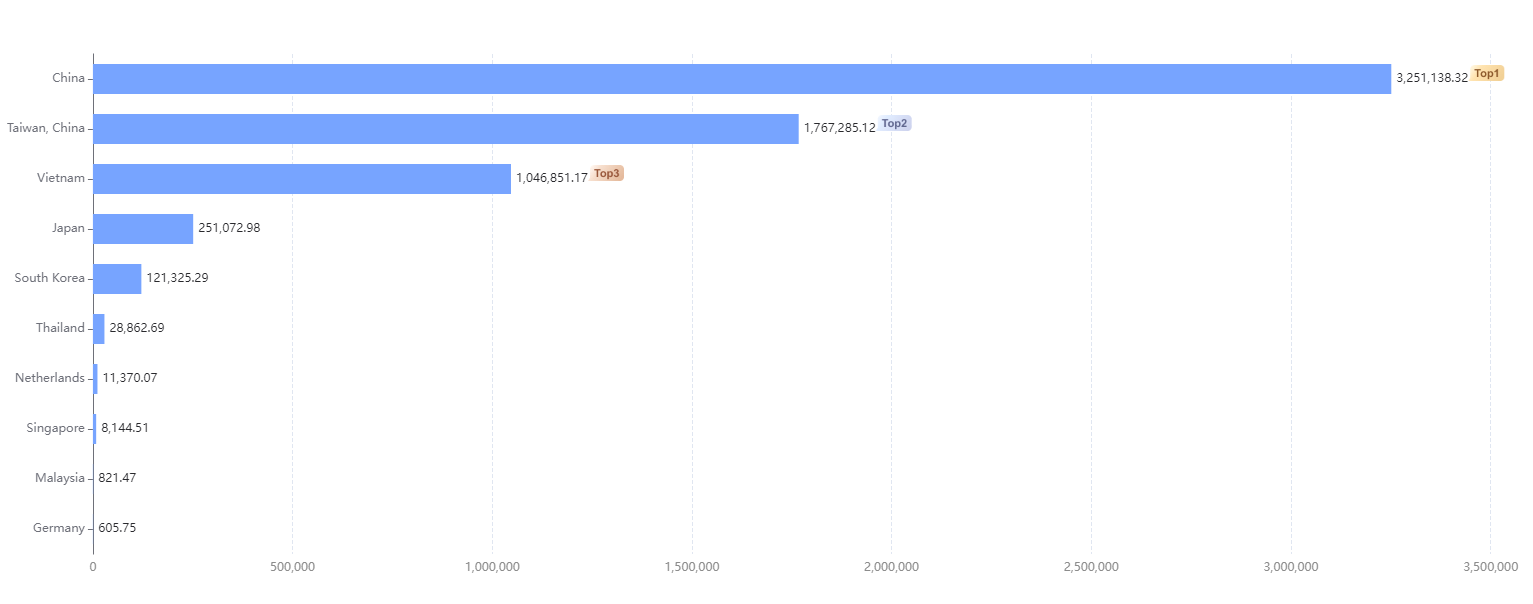

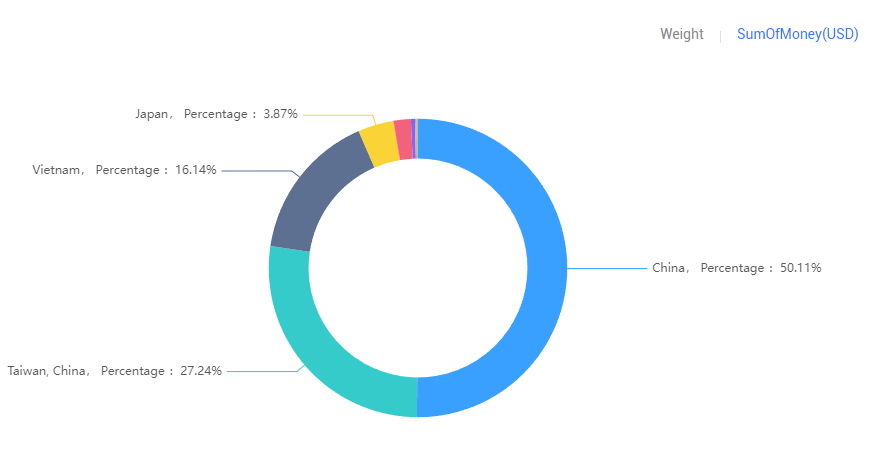

Trade data highlights this reliance: among all import partners, China holds the largest share at 50.11%, with a value of USD 3.25 million. Other countries also supply cranes to the Philippines, but none at a comparable scale. This indicates that international suppliers—particularly China—remain an important source for sustaining the Philippine crane industry.

Growing Market Demand for Overhead and Gantry Cranes in the Philippines

The Philippines is experiencing steady growth in manufacturing and infrastructure, creating notable demand for overhead and gantry cranes. These lifting solutions play a critical role in improving efficiency, safety, and space utilization across production and logistics facilities.

Renewable Energy in the Philippines

The Philippine Energy Plan (2020–2040) emphasizes renewable energy, with over 655 GW hydropower potential and wind resources of 94 GW onshore and 170 GW offshore. Hydropower remains a major contributor, while wind projects are rapidly expanding.

Steel Industry in the Philippines

SteelAsia operates six mills nationwide, producing 3 million metric tons of rebar in 2023, with plans to double capacity. In large-scale production and storage, bridge cranes are essential for safe and efficient lifting of heavy steel products, ensuring smooth workflow and workplace safety.

Automotive Industry in the Philippines

The 2024 ASPBI – Manufacturing Section (Preliminary Results) reported that motor vehicle manufacturing in the Philippines reached PhP 399.69 billion in revenue, with nearly 100,000 workers in auto parts production.

As production expands, handling heavy components like engines and chassis requires greater efficiency. Overhead cranes improve safety and productivity, making them increasingly vital for the country's growing automotive industry.

Food and Beverage Manufacturing in the Philippines

The 2024 ASPBI – Manufacturing Section (Preliminary Results) shows food manufacturing had 7,162 establishments (30.7%) and beverage manufacturing 2,995 establishments (12.8%) in 2022, making it one of the country's strongest industries.

To meet strict hygiene standards, many facilities rely on cleanroom cranes for safe and contamination-free handling of ingredients and equipment, ensuring both efficiency and product quality.

Philippines Overhead Crane Regulations and Compliance

Before purchasing an overhead crane in the Philippines, it's essential to understand local requirements. DOLE mandates inspection and certification, TESDA sets operator training standards, and maintenance must comply with occupational safety laws. Knowing these regulations in advance helps ensure smooth approval, safe operation, and long-term reliability.

In the Philippines, overhead and gantry cranes are strictly regulated under the Department of Labor and Employment (DOLE) and the Technical Education and Skills Development Authority (TESDA). DGCRANE fully supports and complies with these safety standards to ensure reliability, operator protection, and long-term performance.

Operator Training and Licensing (TESDA Standards)

- All crane operators must undergo TESDA-recognized training programs and pass the National Skills Certification exams.

- Only licensed operators are legally permitted to handle overhead or gantry cranes on construction sites.

- This ensures safety and minimizes risks during crane operations.

Regular Inspection and Preventive Maintenance

DOLE regulations require:

- Daily inspections carried out by certified mechanics and operators, following standards from TESDA and ACEL, Inc.

- Periodic professional inspections performed by DOLE-accredited inspectors, based on equipment supplier standards.

- Any crane that does not meet minimum safety requirements must be immediately withdrawn from service until repaired.

- Contractors and crane owners are required to maintain a logbook for each machine, recording inspections, maintenance, and repair activities.

Operator Management and Safety Protection

- Only licensed operators may operate overhead or gantry cranes.

- Operators and riggers must wear mandatory Personal Protective Equipment (PPE) at all times.

- Safety is a shared responsibility between the contractor, the equipment supplier, and the operator.

Why DGCRANE is Your Trusted Partner in the Philippines

At DGCRANE, we recognize that the Philippine market demands not only advanced lifting solutions but also strict adherence to local and international standards. That's why every crane we deliver is backed by both compliance assurance and a global service system that supports you far beyond delivery.

Compliance You Can Rely On

- Certified Quality: All cranes meet international certifications (ISO, CE, SGS, EAC) for global reliability.

- Philippine Safety Standards: Fully aligned with DOLE inspection and certification requirements.

- TESDA-Ready Training: Operator training materials tailored to Philippine standards.

- Regulation-Aligned Maintenance: After-sales guidance that matches local safety and operational laws.

Global Service That Supports Your Success

- Flexible Payment Options: L/C, T/T, wire transfer, and more with transparent, secure processes.

- Reliable Logistics: Sea freight as standard, air freight for urgent needs, and door-to-door delivery.

- On-Site Expertise: Professional engineers for installation and commissioning, ensuring a fast, trouble-free start-up.

- Ongoing Support: Long-term technical assistance, spare parts supply, and rapid response to keep operations smooth.

With DGCRANE, you're not just buying a crane—you're investing in safety, compliance, and long-term reliability, supported by a world-class service system that ensures your operations in the Philippines run efficiently and without interruption.

DGCRANE Export Cases in the Philippines: Proven Experience, Trusted by Local Clients

DGCRANE has built a strong reputation in the Philippines through multiple successful crane export projects. With extensive experience in cross-border delivery, installation, and after-sales support, we understand the unique requirements of Philippine customers and provide solutions that ensure safety, reliability, and compliance.

Here we present four selected cases from many projects completed in the Philippines. These examples highlight our rich export experience, customer-focused service, and long-term commitment to the Philippine market.

Successful Delivery of 8 Sets of A5 Double Girder Gantry Cranes and 1 Set of Double Girder Overhead Crane

Application: Indoor heavy-duty material handling

At the end of October 2019, we successfully delivered a batch of cranes and spare parts to our client in the Philippines. The whole shipment required a total of 18 sets of 40′ high open-top containers for transportation.

Since the client's working conditions required frequent and heavy-duty operations, we specially designed the A5 duty group double girder gantry cranes equipped with QD trolleys, ensuring stable, safe, and efficient performance under high-intensity workloads.

Repeat Order of Gantry & Overhead Cranes for Steel & Equipment Handling

Application:

Steel warehouse & production workshops – lifting steel bars, heavy motors, and gearboxes

We delivered a batch of cranes to our long-term customer in the Philippines, requiring 11 × 40′ high open-top containers.

- 4 sets of 16t gantry cranes (A5): Repeat order after successful delivery of 16t & 25t gantry cranes in 2019, proving customer satisfaction and trust.

- 5 sets of 10t & 15t overhead cranes (A5 & A3): Customized for a new project, designed for heavy-duty and frequent lifting operations in warehouses and production workshops

Delivery of Semi-Gantry & Overhead Cranes | Heavy-Duty A5 Design for Steel Handling

Application: Steel plant workshop – lifting steel bars, billets, and bundled rebar

In July 2020, we delivered 3 sets of 10t semi-gantry cranes (A5) and 2 sets of 10t overhead cranes (A3) to our client in the Philippines, requiring 9 × 40′ high open-top containers.

- The A5 semi-gantry cranes are designed for frequent heavy-duty lifting of steel bars and billets, ensuring stability and efficiency.

- The A3 overhead cranes are used for bundled rebar handling. Considering the limited workshop space, we optimized the design with an integrated hoist instead of the conventional trolley.

500kg Portable Gantry Crane | Low-Headroom Customized Solution

Application: Workshop with strict height limits – lifting light loads and equipment

500kg Portable Gantry Crane | Low-Headroom Customized Solution

In February 2025, we delivered a 500kg manual portable gantry crane with a low-headroom electric chain hoist to a client in the Philippines.

- Compact design to maximize lifting height in confined space

- Portable structure for flexible indoor use

Conclusion

The Philippine market for overhead and gantry cranes is marked by strong demand across key industries—from automotive and food processing to steel and renewable energy. However, with limited domestic manufacturing capacity, the country remains heavily reliant on imports, with China leading as the primary supplier.

For Philippine companies, this means that choosing the right international partner is essential. With proven export experience, deep understanding of local compliance requirements, and a comprehensive global service system, DGCRANE stands out as a trusted provider. By combining international quality with Philippine regulatory support, DGCRANE ensures that every project delivers safety, reliability, and long-term value.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!