Overhead and Gantry Crane in Indonesia: Market Insights and DGCRANE Solutions

Table of Contents

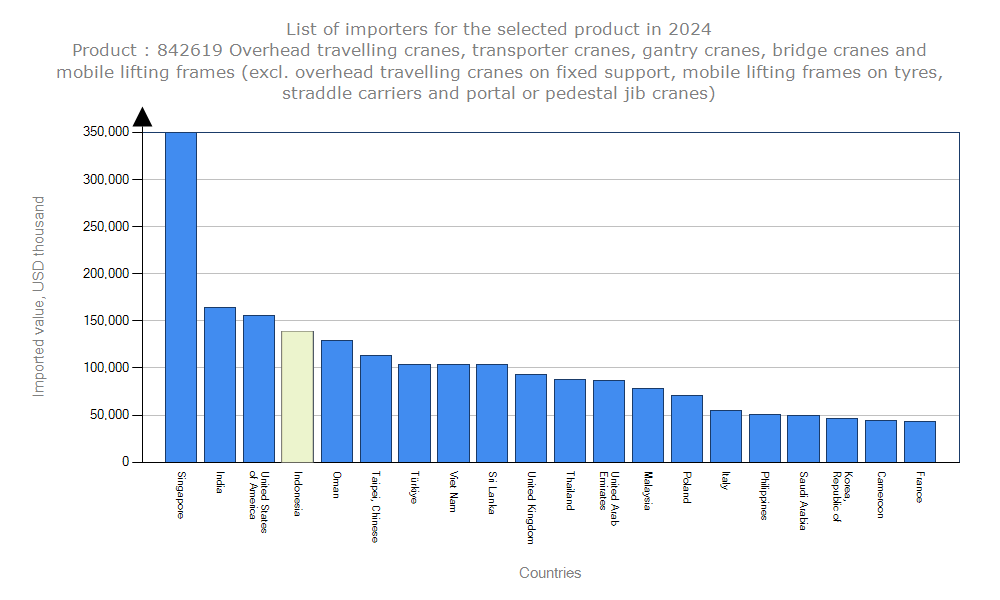

In 2024, Indonesia's imports of bridge and gantry cranes (HS 842619) reached USD 138 million, ranking fourth among global importers and highlighting its demand at the international level. In the same year, the trade deficit stood at USD 135 million, indicating that Indonesia is almost entirely dependent on imports to meet its crane demand, with domestic manufacturing capacity remaining weak and foreign suppliers holding a dominant position in the market.

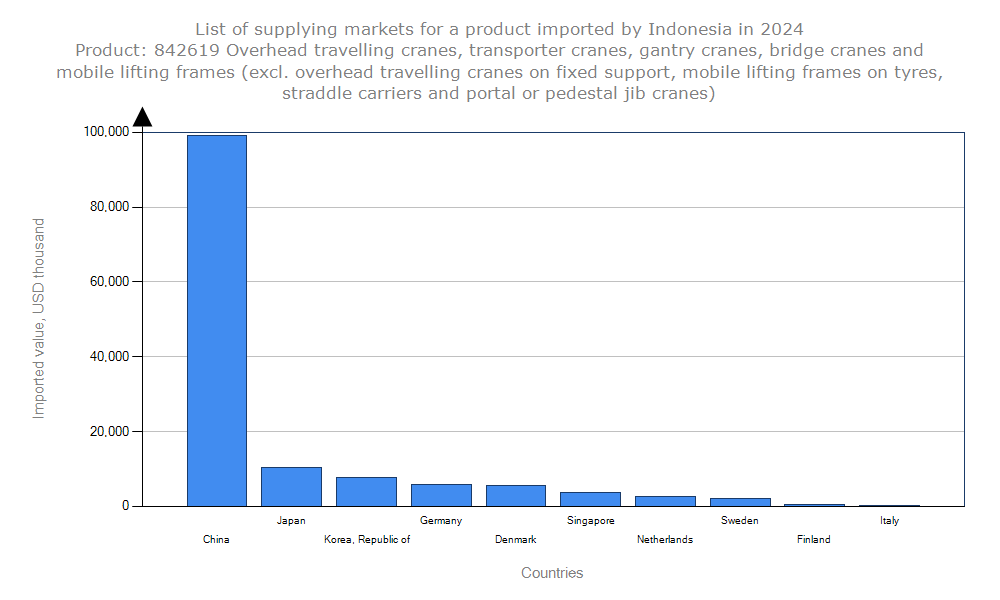

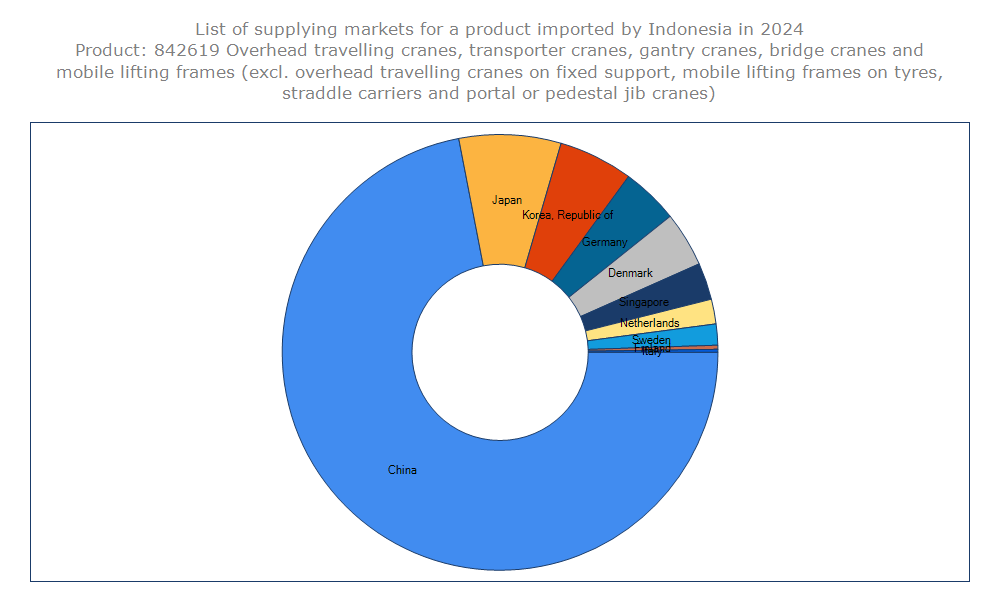

China dominates Indonesia's imports with a 71.8% share, nearly monopolizing the market. This strength comes not only from competitive pricing, fast delivery, and a broad product range, but also from technological upgrades that allow Chinese suppliers to offer high-end and customized solutions for ports, mining, and large-scale industrial projects. In contrast, Japan, Germany, and South Korea mainly serve the high-end segment with precision and advanced automation. Though their market share is smaller, they remain competitive in specialized, high-specification projects.

It is worth noting that between 2020 and 2024, the average annual growth rate of imports was as high as 27%, significantly higher than that of general industrial equipment. This trend clearly reflects the solid demand driven by Indonesia's recent advances in infrastructure construction, port expansion, mineral resource development, and manufacturing industry growth, which have collectively fueled the rapid expansion of the bridge and gantry crane market.

Indonesia Key Industries Drive Bridge and Gantry Crane Demand

Indonesia, as the largest economy in Southeast Asia, is steadily advancing across key sectors. The shipbuilding industry is strengthening domestic shipyard capacity by leveraging the country's archipelagic geography; the mining sector, rich in coal, nickel, and copper, is expanding value through downstream smelting and processing; ports are accelerating modernization to enhance their role as logistics hubs; and manufacturing continues to expand, with its manufacturing value added ranking 13th globally in 2024. Together, these developments not only boost Indonesia's economic competitiveness but also drive growing demand for heavy industrial equipment, particularly bridge and gantry cranes.

Shipbuilding

Jakarta (ANTARA) – Indonesia has 342 active shipyards across 29 provinces, with an annual newbuilding capacity of 1 million DWT and repair capacity of 12 million DWT. Such large-scale shipbuilding and repair work involves lifting hull blocks, engines, and heavy steel parts, which makes overhead and gantry cranes essential. The wide presence and steady activity of shipyards therefore, create consistent demand for these cranes.

Mining and Smelting

Indonesia is rich in minerals such as coal, nickel, copper, and bauxite, and has been enhancing value through downstream smelting and processing. In smelting and refining operations, the handling of large furnaces, electrolytic cells, ingot molds, and other heavy equipment relies heavily on bridge and gantry cranes, making downstream mining expansion a direct driver of demand for such equipment.

Port and Logistics

Indonesia's main ports—Tanjung Priok, Tanjung Perak, and Belawan—are seeing steady growth. CEIC data shows throughput reached 12.38 million TEUs in 2022, and Pelindo reported a 6% rise to 9.3 million TEUs in the first half of 2025. To handle this growth, Tanjung Priok added two new quay cranes from South Korea in 2025. Meanwhile, the government's “Sea Toll Road” program is prompting regional ports to adopt modern gantry cranes. Together, these developments are driving strong demand for port gantry cranes across Indonesia.

Manufacturing

Indonesia's manufacturing sector has expanded rapidly in recent years. By 2024, its manufacturing value added reached USD 265.07 billion, ranking 13th globally, while in the second quarter of 2025, non-oil and gas manufacturing grew by 5.60% year on year, outpacing overall economic growth. This continuous expansion means more new and expanded factories, increasing demand for heavy equipment handling and production logistics, which in turn drives higher procurement of bridge and gantry cranes.

Top Reasons China Dominates Indonesia’s Crane Imports

- Cost and Value Advantage: By virtue of a complete industrial chain and large-scale production, Chinese cranes have lowered manufacturing costs, and their products have achieved a balance between price and performance, which can effectively meet the needs of Indonesia’s industrial and infrastructure development.

- Comprehensive Product Range: From light-duty single-girder overhead cranes to heavy-duty gantry cranes, Chinese suppliers provide a full range of products covering ports, metallurgy, mining, manufacturing, and other applications.

- Geographic and Cooperation Benefits: Mature China-Indonesia shipping routes ensure lower logistics costs and shorter delivery times, while numerous Chinese-funded infrastructure projects under the Belt and Road Initiative directly drive demand for Chinese-manufactured cranes.

- Customization and Fast Service Response: Capable of quick modifications to suit Indonesia’s environment (anti-moisture, anti-corrosion, tropical adaptation), with faster response compared to European and American manufacturers.

Why Choose Chinese Crane Supplier DGCRANE for Indonesia

Building on China’s overall manufacturing advantages, DGCRANE stands out with the following unique strengths:

- Extensive Export Experience: Over 10 years of international market experience, familiar with Indonesia and Southeast Asia's certifications, standards, and operating practices to ensure smooth delivery and compliance.

- Customized Engineering Solutions: A professional engineering team provides tailored design and installation plans for different working conditions—ports, factories, and mines—rather than relying on standardized products.

- On-Site Installation & Service: Offering on-site installation, commissioning, and training with quick response to customer needs, reducing operational and maintenance challenges.

- Adaptability & Reliability: Equipment is specially designed for Indonesia’s tropical environment, with anti-moisture, anti-corrosion, and high-temperature protection to ensure stable performance.

- Proven Track Record: Multiple successful project cases have built a solid reputation and long-term trust in the Indonesian market.

DGCRANE Overhead and Gantry Crane Export Cases in Indonesia

DGCRANE has extensive experience exporting bridge and gantry cranes to Indonesia and understands local policies, market conditions, and industry needs. The company has served ports, industrial parks, timber mills, and steel plants, offering tailored solutions and dispatching professional teams for on-site installation and commissioning.

The following highlights four representative cases.

16T MGZ Double Girder Gantry Crane for Timber Mill

DGCRANE exported four sets of 16T MGZ double girder gantry cranes equipped with electric hydraulic grabs to an Indonesian timber mill. Designed for handling logs, each crane features a single cantilever with an effective length of 4 meters, tailored to the mill's operational needs.

The cranes adopt European-imported components and are specially configured for outdoor use in Indonesia's climate, including rain covers on the trolley and corrosion-resistant chlorinated rubber paint.

Key Specifications:

- Capacity: 16T

- Span: 23.5m

- Cantilever: 4m (one side)

- Lifting Height: 8m

- Lifting Speed: 0–13 m/min

- Trolley Speed: 0–44.6 m/min

- Crane Traveling Speed: 0–70 m/min

- Power: 3Ph 380V 50Hz

4 Sets of HD Single Girder Overhead Cranes Exported to Indonesia

In February, we confirmed the initial solution and quotation with the customer. In April, their representatives visited our factory, after which the design was adjusted to include runway beams. By October, four sets of HD single girder overhead cranes were delivered to Indonesia and installed under our engineers' guidance within one month. The whole project, from inspection to installation, lasted about nine months.

Crane Specifications:

- Country: Indonesia

- Model: HD Single Girder Overhead Crane

- Capacity: 5t

- Span Length: 35m

- Lifting Height: 8.5m

- Work Duty: A5

- Power Source: 380V / 50Hz / 3Ph

- Control Mode: Remote control

- Quantity: 4 sets

MG 32 Ton Gantry Crane for lifting steel billets

In September 2020, the customer first contacted us regarding hook blocks. After further communication, they inquired about a gantry crane project for an Indonesian steel factory. The end user already had a similar gantry crane in operation and required a comparable design for lifting steel billets.

During the five months of technical discussions, the project specifications were adjusted several times: the capacity increased from 20 tons to 32 tons, the upper-rotate design was changed to a lower-rotate design, and the configuration was upgraded from Chinese brands to well-known European brands.

Technical Specifications:

- Capacity: 32t

- Span Length: 32m + 8.5m + 8.5m

- Lifting Height: 10.5m

- Work Class: A6

- Control Mode: Cabin control + wireless remote control

- Power Source: 380V / 50Hz / 3Ph

- Main Lifting Motor: Siemens

- Main Lifting Reducer: SEW

- Cross Traveling Motor/Reducer/Brake: SEW

- Crane Traveling Motor/Reducer/Brake: SEW

- Electrical Components: Schneider

- Frequency Inverter: Schneider

- PLC: Siemens

- Installation Site: Indonesia

2 Sets of 10T Single Girder Overhead Crane Exported to Indonesia

On September 19th, 2013, two sets of 10 ton single girder overhead cranes were delivered to Indonesia.

Each crane is designed with a span of 11.325 meters and a travel length of 30 meters, with a lifting height of 6 meters. The lifting mechanism adopts a double-speed design, meeting the customer's operational requirements for material handling.

Basic Parameters:

- Lifting Capacity: 10t

- Lifting Height: 6m

- Span: 11.325m

- Travel Length: 30m

- Lifting Speed: Double Speed

Conclusion

With extensive export experience and a deep understanding of Indonesian policies and market conditions, DGCRANE demonstrates outstanding expertise in the Indonesian market. The company not only provides high-quality bridge and gantry cranes but also dispatches professional teams for on-site installation and commissioning, ensuring each project is delivered smoothly and quickly put into operation.

Contact us today to let DGCRANE provide customized crane solutions for your Indonesian projects and help your operations run efficiently.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!