OSHA Overhead Crane Regulations: A Complete Compliance Guide for Equipment Buyers

Table of Contents

Why OSHA Compliance Matters for Overhead Crane Buyers

For overhead crane buyers—especially those operating in the U.S.—understanding OSHA compliance is not optional. It's a critical part of ensuring workplace safety, minimizing legal exposure, and protecting both workers and investments. From installation and inspection to operator procedures and documentation, OSHA outlines strict standards that must be considered long before a crane ever lifts its first load.

Crane-related fatalities remain a serious concern in the U.S. workplace. According to the U.S. Bureau of Labor Statistics (BLS), an average of 42 to 44 crane-related deaths occur annually. Between 2011 and 2017 alone, 297 fatalities were reported. In 2023, the BLS recorded 5,283 total workplace deaths, and crane incidents—particularly in the construction sector—continued to account for a significant share.

Beyond the human cost, OSHA enforces strict accountability. A review of 249 overhead crane incidents uncovered 838 OSHA violations, resulting in 133 injuries and 133 fatalities. Many of these cases involved lapses in inspection, training, or load handling procedures—areas governed directly by OSHA's standards.

For buyers, this highlights a critical point: compliance isn’t just the operator's responsibility. Equipment must be designed, installed, inspected, and documented according to OSHA regulations. Failing to do so can expose companies to serious legal and operational risks.

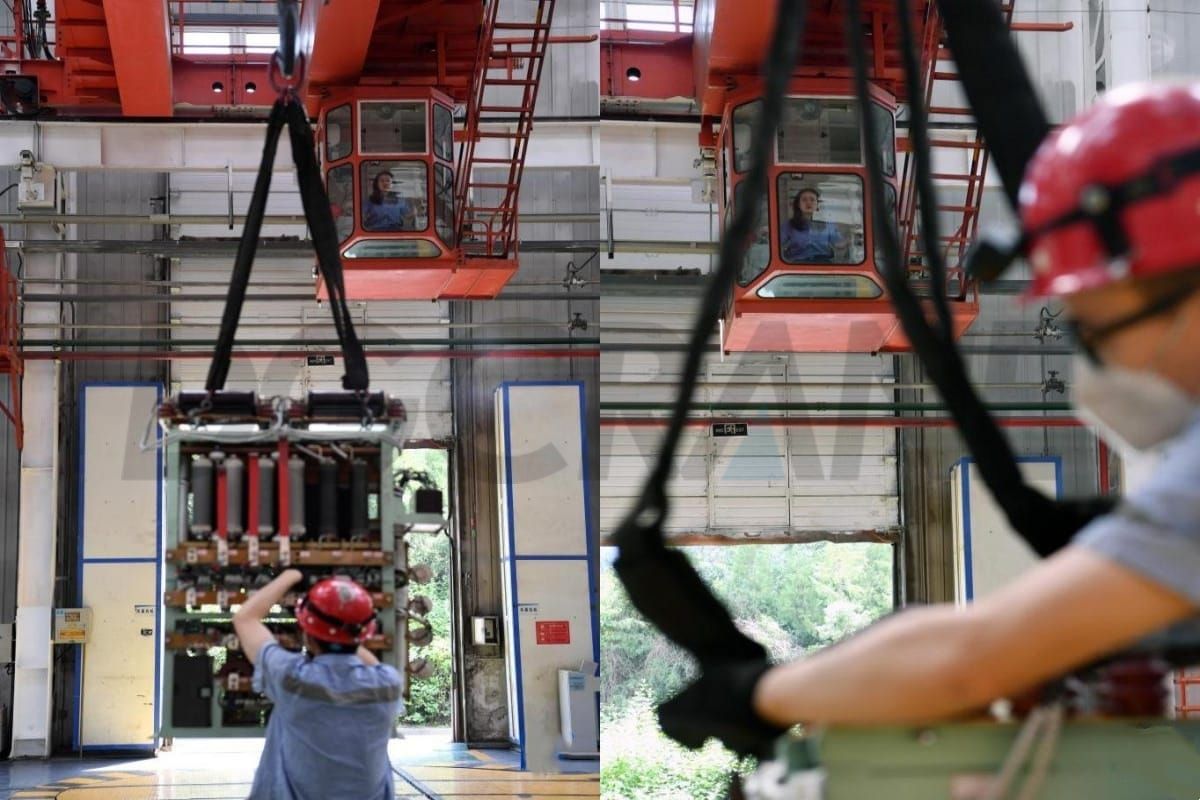

That's why it's essential to work with manufacturers who understand the full scope of OSHA requirements. At DGCRANE, we support our clients throughout the compliance process—from English-language operation manuals and training videos to remote installation guidance and inspection support—ensuring your crane is both safe and regulation-ready from day one.

OSHA Overhead Crane Inspection Requirements

(According to OSHA 29 CFR 1910.179(j))

OSHA requires that all overhead (bridge-type) cranes undergo inspections at different intervals, depending on their usage and condition. These inspections are critical for maintaining safe operation and avoiding equipment failure.

Inspections fall into three categories:

| Inspection Type | When | Purpose |

| Initial Inspection | Before first use (new or modified) | Ensure OSHA compliance before crane enters service |

| Frequent Inspection | Daily to monthly intervals | Detect wear, leaks, or safety hazards through routine checks |

| Periodic Inspection | Every 1 to 12 months | Comprehensive review of structure, mechanics, and electricals |

Frequent Inspection

(To be done daily or monthly, depending on the item)

Daily checks:

- Functional operating mechanisms (maladjustment)

- Hydraulic/pneumatic systems (leaks or deterioration)

- Hooks (deformation or cracks – also require monthly documented inspection)

- Hoist chains (twist, stretch, or excessive wear – also monthly documented inspection)

General checks:

- Excessive wear in functional mechanisms

- Rope reeving (must comply with manufacturer's recommendations)

Documentation required for hook and chain monthly inspections:

- Inspection date

- Inspector's name/signature

- Identifier (serial number or equivalent)

Periodic Inspection

(To be done every 1 to 12 months, based on usage severity)

| Inspection Area | What to Inspect |

| Structural | Deformed, cracked, or corroded members; loose bolts or rivets |

| Mechanical | Drums, sheaves, bearings, pins, gears, shafts; brake linings; load/wind indicators |

| Power Sources | Diesel, electric, gasoline engines – check for compliance/performance |

| Drive System | Chain sprockets and chain stretch |

| Electrical Systems | Controller contacts, limit switches, pushbutton stations |

Cranes Not in Regular Use

Idle 1–6 months → Perform Frequent Inspection + functional test (per section m(2))

Idle over 6 months → Perform Frequent + Periodic Inspections

Standby cranes → Inspect at least every 6 months

To ensure ongoing compliance, OSHA requires routine inspections of overhead cranes—both frequent (daily to monthly) and periodic (monthly to annually), depending on the equipment and use intensity.

For a detailed breakdown of what to inspect and how often, refer to our Gantry Crane Inspection Checklist, which outlines key points that also apply to overhead and bridge cranes.

Mandatory Testing Before Use: Operational and Load Tests

Beyond training, OSHA requires that each crane be tested and inspected before it is put into service. These tests include functional operations—such as hoisting, bridge travel, and safety devices—and a rated load test up to 125% of capacity. Choosing a manufacturer who understands and supports these compliance steps can save buyers time, risk, and money.

Before an overhead crane can be used in the workplace, OSHA requires it to undergo a series of operational and rated load tests.

- Operational tests include hoisting, lowering, trolley movement, bridge travel, and the performance of safety devices like limit switches.

- Rated load testing ensures the crane can handle up to 125% of its rated capacity safely, unless otherwise specified by the manufacturer.

- All test results must be documented and kept on file for future inspection.

These tests are not optional—they are a regulatory requirement designed to protect workers and ensure that new or modified cranes are safe before they ever lift a load.

Safe Load Handling Practices: What OSHA Requires During Operation

(Based on OSHA 1910.179(n))

Load Limits

Never exceed the rated load unless performing a supervised load test as defined under section (k).

Attaching the Load Properly

- To ensure safe lifting, operators must follow strict rigging procedures:

- Hoist ropes/chains must be free of kinks or twists, and must not be wrapped around the load.

- Loads must be attached using slings or other OSHA-approved devices.

- The sling must clear all obstacles before the lift.

Lifting and Moving the Load

Before lifting:

- Ensure the load is properly balanced and secure.

- Hoist ropes must not be kinked, and multi-part lines must not be twisted.

- The hook should be positioned directly over the load to avoid swinging.

During hoisting:

- Avoid sudden starts or stops.

- Ensure the load does not hit any obstacles.

- Side pulls are not allowed unless specifically approved by a qualified person.

- Never lift, lower, or travel a load while someone is on the hook or the load.

- Avoid carrying loads over people — this is the employer’s responsibility to enforce.

- Test the brakes before lifting heavy loads: lift the load a few inches and apply brakes to confirm function.

- Do not lower the load so far that less than two wraps of rope remain on the hoist drum.

- If two cranes are used simultaneously, a qualified person must oversee and direct the entire operation.

Operator Responsibilities During Lifting

- The operator must not leave the controls while a load is suspended.

- A warning signal must be sounded:

- When the bridge is started

- When the load or hook moves near or over personnel

Hoist Limit Switch Safety

- At the start of every shift, operators must test the upper limit switch with no load:

- Do it slowly or by inching, to avoid collision.

- If it doesn’t work properly, report it immediately.

- The limit switch must never be used as a regular stop control during normal operation.

Handling the load safely is a major component of OSHA-compliant crane operation. Operators must be trained to attach loads correctly, avoid side pulls, prevent lifting over personnel, and test limit switches before each shift. OSHA prohibits exceeding rated load limits and requires brakes and slings to be tested and inspected regularly. In short, operator awareness, proper rigging, and disciplined lifting procedures are not just best practices — they're legal requirements.

The Cost of Non-Compliance: Real Accidents Caused by Ignoring OSHA Rules

Each year, dozens of crane-related deaths are reported across U.S. worksites—many of which stem directly from violations of OSHA safety standards. These real-world incidents demonstrate the human and financial costs of non-compliance:

- Case 1: Improper rigging led to the fatal collapse of a stamping die.

- Case 2: A failed wire rope caused a falling mold component to strike and kill an operator.

In each case, the tragedy could likely have been prevented by adhering to OSHA regulations regarding inspection, rigging, and control procedures. For equipment buyers, these incidents highlight the importance of choosing crane systems that support compliance—and ensuring proper training, inspection protocols, and safety controls are in place from day one.

Case 1: Improper Rigging and Inspection Leads to Fatal Die Strike

In July 2024, a worker was using an overhead crane to move a large stamping die. One of the four eyebolts securing the die was not properly fastened. As the load was lifted, the unsecured bolt slipped, causing the die to shift and separate. The upper half of the die fell and fatally struck the operator.

Violation: Improper rigging and failure to ensure secure attachment points before lifting—a direct breach of OSHA’s load handling and inspection standards.

Outcome: One fatality due to preventable rigging failure.

Case 2: Fatal Overhead Crane Failure Due to Wire Rope Malfunction

In June 2024, a crane operator was lifting a 29,150-pound mold using a 20-ton overhead gantry crane. During the hoisting operation, the wire rope failed, dropping the mold onto another below. A heavy back plate sheared off during the impact and struck the operator, killing him instantly.

Violation: Potential failure in hoist inspection, maintenance, or load handling procedures, violating OSHA’s requirements for routine crane inspection and equipment integrity.

Outcome: One fatality resulting from mechanical failure that could have been detected with proper inspections.

Source of Cases: OSHA Accident Investigations

How DGCRANE Supports Buyers with OSHA Compliance

At DGCRANE, we understand that compliance with OSHA standards is as important as the quality of the equipment itself—especially for clients operating in the U.S. and other regulated markets. That’s why we provide more than just cranes. We offer a range of services to help our clients operate safely and legally.

Our Compliance Support Services

English Operation Manuals

We supply all exported cranes with professionally written English-language manuals to meet OSHA documentation requirements.

Basic Training Materials and Video Demonstrations

Upon request, we can provide visual training content such as operation tutorials, safety reminders, and component overviews to help clients conduct internal training.

Remote and On-Site Installation Support

To ensure your crane is installed correctly and in full compliance with OSHA standards, our engineering team offers remote installation and commissioning guidance. For projects requiring additional support, on-site installation by certified technicians is also available.

Safety & Inspection Guidance

We offer advice on daily and periodic inspection routines based on OSHA 1910.179 standards to support your maintenance team’s compliance efforts.

Whether you’re a first-time crane buyer or expanding your operations in a regulated market, DGCRANE is your trusted partner in safety, compliance, and long-term support.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!