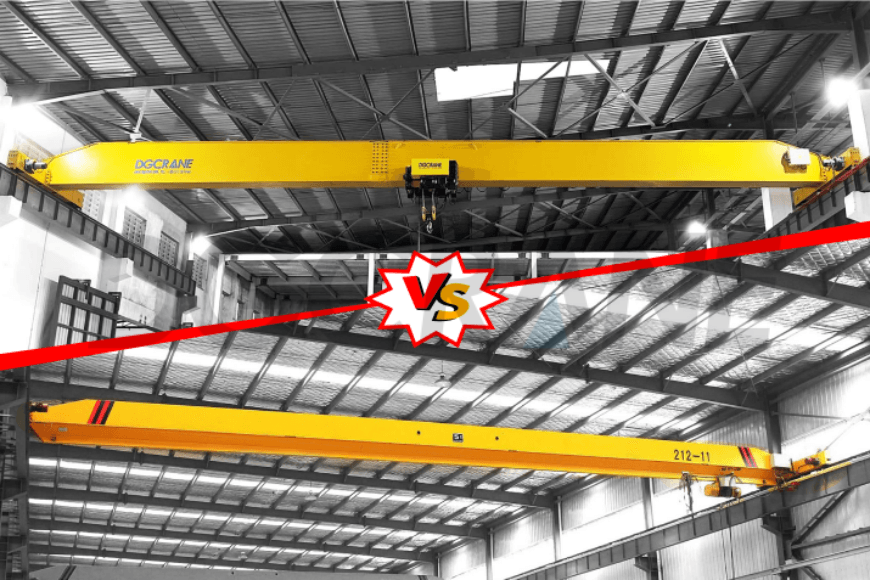

Lightweight Overhead Crane vs Light Duty Overhead Crane

Table of Contents

Overhead cranes play a critical role in industrial material handling, improving productivity and safety across a wide range of sectors. However, not all cranes are created equal. Two terms that are often used interchangeably but have distinct differences are “Lightweight Overhead Crane” and “Light Duty Overhead Crane.” Understanding their unique characteristics is essential when selecting the right crane for your operation.

In this article, we'll break down the differences, explore typical applications, and offer expert guidance on how to choose the most suitable crane based on your needs.

What is a Lightweight Overhead Crane?

A Lightweight Overhead Crane is designed with a focus on minimal self-weight and modular construction. This reduces the load on building structures while offering greater flexibility and adaptability. With a short design cycle and high level of standardization, it can be quickly configured to suit different workstations and operational needs.

What is a Light Duty Overhead Crane?

A Light Duty Overhead Crane is defined by its low usage frequency. These cranes are typically rated for lower-duty classes (A1 to A3), suitable for maintenance work, infrequent lifting tasks, or light-load operations.

Lightweight Overhead Crane vs Light Duty Overhead Crane

To clearly illustrate the differences between a Lightweight Overhead Crane and a Light Duty Overhead Crane, this article presents two representative models for comparison. By examining key technical dimensions side by side, the contrast helps highlight how each type of crane is designed to meet different operational priorities.

|

|

|

| Product | HD European Type Single Girder Overhead Crane (Lightweight Overhead Crane) | LD Single Girder Overhead Crane(Light Duty Overhead Crane) |

| Lifting Capacity | 5 ton | 5 ton |

| Span | 16m | 16m |

| Duty Class | A5 | A3 |

| Total Weight | 3.67 ton | 4.29 ton |

Structural Weight

Compared to the Light Duty Overhead Crane, the Lightweight Overhead Crane has a significantly lower self-weight. Its overall structure is optimized through lightweight and modular design, effectively reducing the load on the building floor and roof structure. This feature makes it particularly suitable for facilities with limited structural bearing capacity or stringent load control requirements.

Duty Classification

In terms of duty classification, the Lightweight Overhead Crane typically offers a wider range of applicability, covering classes A1 to A6. This means it is suitable not only for light-duty, low-frequency operations, but—depending on its structure and configuration—can also handle medium-frequency and even relatively high-intensity lifting tasks. These cranes are designed with an emphasis on lightweight and modular construction, enabling them to maintain a low self-weight while accommodating more demanding operational requirements.

In contrast, the Light Duty Overhead Crane is generally limited to duty classes A1 to A3 and is primarily intended for very low-frequency applications. Its design focuses on meeting basic lifting needs and is not suitable for long-term or high-frequency usage.

Therefore, if your application requires higher usage frequency and sustained operational capacity, the Lightweight Overhead Crane may be the more flexible and adaptable choice.

Work Efficiency

In terms of work efficiency, the Lightweight Overhead Crane generally offers greater flexibility and faster response times, making it especially suitable for frequent and rapid material handling tasks. Its lightweight structure, combined with a modular design, allows for quicker installation and deployment, as well as fast adaptation to different workstations or operational environments—ultimately enhancing overall productivity.

In contrast, the Light Duty Overhead Crane, while well-suited for low-frequency daily use, performs less effectively in scenarios that require sustained high-efficiency operation. It places more emphasis on stability and cost-effectiveness, making it ideal for well-planned, slower-paced workflows.

Therefore, if your production cycle is fast and your lifting tasks vary frequently, the Lightweight Overhead Crane is better positioned to meet high-efficiency demands. On the other hand, for periodic maintenance or non-continuous operations, the Light Duty Overhead Crane offers a more practical and cost-controlled solution.

Typical Application Scenarios

The Lightweight Overhead Crane is commonly used in environments that demand high equipment mobility and lightweight construction, such as:

- Automotive Assembly Lines

Workstations frequently require lifting of small to medium-sized components, such as hoods and transmissions. This demands a crane that is lightweight, easy to operate, and capable of supporting high-frequency operations throughout the day. - Electronics and Appliance Manufacturing Workshops

In assembly areas for products like TVs and refrigerators, equipment is used to quickly handle casings, modules, and finished goods. Though the loads are relatively light, the high frequency of movement benefits from a lightweight crane structure that reduces the burden on the building infrastructure. - Packaging and Logistics Lines

During packing, sorting, and material transfer, lightweight goods or bins are lifted frequently. High operational efficiency is required, and a lightweight crane structure helps increase workflow speed. - Cleanrooms in the Food or Pharmaceutical Industries

These environments impose strict requirements on equipment weight and design. Lightweight cranes made from aluminum alloy or stainless steel meet hygiene standards while enabling continuous handling of raw materials or packaged products. - Workstation-Based Operations

Especially in multi-station or mobile work setups—such as small parts assembly or maintenance stations—cranes must be flexible and frequently used for lifting and positioning tasks.

Light Duty Overhead Cranes are more suitable for environments with lower work frequency but where the equipment needs to remain permanently installed, such as:

- Hydropower Stations and Municipal Facilities Maintenance

In areas like pump rooms, hydropower stations, or underground wells, cranes are mainly used for periodic maintenance and equipment replacement. Although lifting operations are infrequent, the equipment must offer high stability and corrosion resistance. - Underground Vault Maintenance

For urban drainage, power, or telecommunications systems, maintenance of underground vaults often relies on portable or foldable cranes. These are used over long periods but for low-intensity lifting tasks, with a focus on portability, safety, and quick deployment. - University Laboratories or R&D Institutions

Experimental equipment or samples may occasionally need to be lifted or positioned. Since usage is infrequent, small manual single-girder cranes or lightweight electric hoist systems are often chosen for their flexibility and cost-efficiency. - Warehousing and Reserve Areas

In storage zones for molds, equipment, or bulk materials, cranes are typically used only during loading, unloading, or occasional repositioning. The limited workload makes light-duty, simple-structured products an ideal fit.

Whether you prioritize equipment lightness, installation flexibility, or focus more on operating frequency and stability, both the Lightweight Overhead Crane and the Light Duty Overhead Crane demonstrate unique value in their respective applications. The key lies in selecting the most suitable solution based on your facility structure, usage intensity, and operational needs.

As a professional crane equipment supplier, DGCRANE offers customized overhead crane systems tailored to your specific requirements. Feel free to contact us for one-on-one selection guidance or to access more success stories and practical resources—making your selection process easier and your procurement more efficient.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!