Light Duty Overhead Cranes: Types, Prices and Global Project Cases

Table of Contents

Looking for reliable lifting solutions for low-frequency, light-load applications? Light duty overhead cranes—also known as light duty bridge cranes—are specifically designed for work environments where lifting tasks are not continuous and the operational demand is minimal. These cranes, typically classified under work duty levels A1 to A3, are ideal for workshops, maintenance areas, and production lines requiring efficient yet economical material handling.

In this guide, we'll explore the most popular light duty overhead crane types, help you understand light duty overhead crane prices, and share real-world project cases from DGCRANE, a trusted exporter of crane systems worldwide. Whether you're searching for a single-girder light duty bridge crane or need custom lifting solutions, this page offers comprehensive insights to help you make an informed decision.

Light Duty Overhead Crane Types

Simple installation, lower cost, and reduced shipping weight.

Maximizes lifting height in buildings with limited vertical space.

Ideal when ceiling height is insufficient but the roof structure can support the load.

Simple structure, low cost, and no dependency on electric power.

Flexible coverage of work areas; easy to install, dismantle, or relocate.

Customizable track layout to fit specific workshop workflows.

Designed for hazardous environments with flammable, explosive, or toxic gases.

Versatile application; requires higher load capacity from building support beams.

Single Girder Overhead Crane

The single girder light duty overhead crane is designed with a compact structure and high overall rigidity, making it one of the most widely used types of cranes in the light duty overhead crane category. It is typically used in combination with CD, MD, or HC type electric hoists, offering an efficient solution for material handling in light to moderate lifting tasks. The rated lifting capacity ranges from 1 ton to 20 tons.

Specifications

- Capacity: 1~20t

- Span length: 7.5m-28.5m

- Lifting height: 6m/9m/12m/18m/24m/30m

- Work duty: A3

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Floor control / Remote control

Low Headroom Overhead Crane

The Low Headroom Overhead Crane is a specially designed bridge crane engineered for facilities with limited vertical clearance. Its optimized structure allows the hook to reach as close as possible to the bottom of the main girder when lifted to the highest point. This design minimizes the required headroom, maximizes the utilization of lifting height, and makes it ideal for workshops or operational areas with restricted overhead space.

Specifications

- Capacity: 1~20t

- Span length: 7.5m-28.5m

- Lifting height: 6m/9m/12m/18m/24m/30m

- Work duty: A3

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Floor control / Remote control

Underslung Overhead Crane

The underslung light duty overhead crane runs on tracks mounted beneath the building's load-bearing roof structure, with the crane fully suspended below. It is ideal for facilities lacking ground space or support columns but with a roof structure capable of bearing loads.

This design frees up floor space and is suitable for light-duty applications, with a lifting capacity of up to 10 tons.

Specifications

- Capacity: 0.5ton-10ton

- Span length: 5.5m-16.5m

- Lifting height: 6m/9m/12m/18m/24m/30m

- Work duty: A3

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Ground control / Remote control

Manual Overhead Crane

A manual light duty overhead crane is a human-powered material handling device widely used in various industrial settings. Unlike electric cranes, it operates through chains or manual hoists without requiring electrical power.

Its main advantages include simple structure, low maintenance costs, and independence from electricity, making it ideal for environments where power is unavailable, unreliable, or where explosive atmospheres render electrical equipment unsuitable.

Free Standing Workstation Bridge Cranes

Free standing workstation bridge cranes are highly adaptable and versatile, making them ideal for workstations where the building structure cannot support overhead loads. They are widely used across various fields such as production material handling, warehousing and logistics, automotive assembly, electronics and semiconductors, as well as the medical and food industries.

Specifications

- Capacity: 125kg to 2000kg

- Work duty: M3/M4

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Floor control / Remote control

Monorail Overhead Crane

A monorail crane is a type of crane that acts as a substitute for conventional cranes and conveyor belts. These cranes are mostly used to relocate materials or products within a limited area. Such sites could be a factory or throughout the working station. Monorail crane design is simple and can be compatible with the structure of the building without major changes.

Explosion Proof Overhead Cranes

The explosion-proof single-girder crane is based on the standard bridge crane, enhanced with explosion-proof motors, electrical components, and additional mechanical safety measures. These features ensure safe operation in explosive environments by preventing fire or explosion risks. The explosion-proof designation is marked as “Ex”.

Specifications

- Capacity: /1ton/2ton/3ton/5ton/10ton/16ton/20ton

- Lifting height: 6m/9m/12m/18m/24m/

- Work duty: A3

- Explosion Proof Grade: ExdIIBT4、ExdIICT4

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Floor control / Remote control

LH Type Double Girder Overhead Crane with Hoist Trolley

The LH-type electric hoist bridge crane features a compact design, low clearance height, light weight, and reduced wheel load. It is widely used for material transfer, assembly, maintenance, and loading/unloading operations in environments such as machine shops, auxiliary workshops in metallurgical plants, warehouses, stockyards, power stations, as well as production workshops in the light textile and food industries. The crane is classified for light to medium-duty work.

Specifications

- Capacity: 5-32/5ton

- Span length: 10.5-31.5m

- Lifting height: 3-50m

- Work duty: A3, A4

- Rated voltage: 220V~690V, 50-60Hz, 3ph AC

- Work environment temperature: -25℃~+50℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

Light Duty Overhead Crane Price

The price of a light duty overhead crane—or light duty bridge crane—can vary significantly based on several key factors. These include the lifting capacity (tonnage), span, lifting height, the level of customization required, and even fluctuations in global steel prices. Every project has unique specifications, so there is no one-size-fits-all answer.

To give you a clearer picture, we’ve presented real project cases from DGCRANE, showcasing different configurations and price points. While these examples are helpful for reference, it’s important to note that the listed prices are indicative only and may not reflect your specific needs.

| Product | Capacity(Ton) | Lifting Height(m) | Span(m) | Power Supply | Price/USD(tax included) |

|---|---|---|---|---|---|

| LD Single-Girder Overhead Crane | 16t | 12.5m | 7.5m | AC 380V 50Hz | $10,283 |

| LD Single-Girder Overhead Crane | 5t | 8.5m | 22.5m | AC 380V 50Hz | $5,507 |

| LD Single-Girder Overhead Crane | 3t | 8.5m | 22.5m | AC 380V 50Hz | $4,634 |

| LX Single-Girder Suspension Overhead Crane | 3t | 9m | 5.5m | AC 380V 50Hz | $1,779 |

| LX Single-Girder Suspension Overhead Crane | 3t | 8.5m | 9.5m | AC 380V 50Hz | $2,414 |

| QB Explosion-Proof Double-Girder Overhead Crane | 16/5t | 14m | 13.5m | AC 380V 50Hz | $61,300 |

| LB Explosion-Proof Single-Girder Overhead Crane | 20t | 12.5m | 13.5m | AC 380V 50Hz | $15,948 |

| LH Type Double-Girder Overhead Crane with Hoist Trolley | 10t | 8m | 10m | AC 380V 50Hz | $20,303 |

| SDQ Manual Single-Girder Overhead Crane | 5t | 7m | 10.5m | AC 380V 50Hz | $1,710 |

What sets DGCRANE apart is our ability to deliver high-quality, cost-effective light duty overhead crane solutions. With in-house manufacturing, strict quality control, and global export experience, we ensure that every crane system not only meets your technical requirements but also provides exceptional value.

Contact us today to get a personalized quote based on your project specifications. Our engineering and sales teams are ready to help you find the most economical solution without compromising on performance or safety.

Light Duty Overhead Crane Cases

With over 10 years of export experience and crane systems delivered to 120+ countries, DGCRANE has earned a strong reputation across industries—from manufacturing and maintenance to energy and logistics. Our professional service team ensures fast response and reliable support, no matter where our clients are located.

Below are just a few examples of our light duty overhead crane projects. Each case highlights different needs and solutions, showcasing our ability to adapt to diverse requirements.

Installation and Test Run of 16-Ton Overhead Cranes in Tanzania

According to the customer's requirements, we arranged for an engineer to go to the customer's site to guide the installation of the crane. We arrived at the customer's site on July 16th and returned to our factory on August 29th. Here are some product and installation pictures.

LDC Single Girder Overhead Crane

- Capacity: 16ton

- Crane Span: 20.02 m

- Lifting height: 7.82m

- Work class: ISO A3;

- Control mode: Pendant control

- Power source: 380V/50Hz/3Ph (48V)

NLH European type Double Girder Overhead Crane

- Capacity: 16ton

- Crane Span: 20.02 m

- Lifting height: 8.5 m

- Work class: ISO A3; FEM 2m

- Control mode: Pendant Control

- Power source: 380V/50Hz/3Ph (48V)

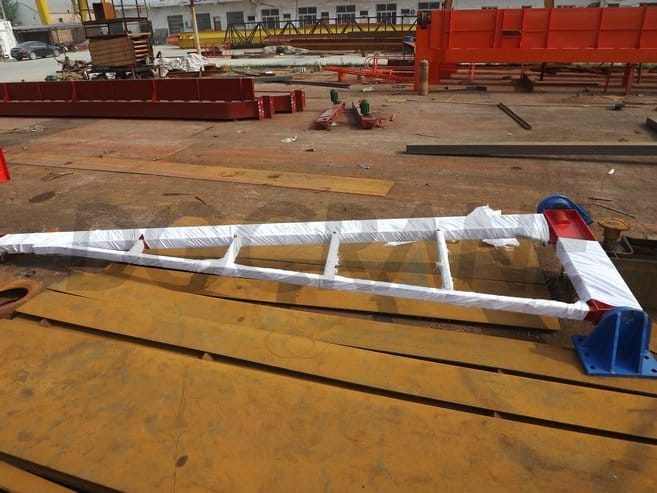

5-Ton European-Type Single Girder Overhead Crane with Steel Structures Exported to Tajikistan

In July 2022, we received an inquiry from a customer in Tajikistan. They were in the process of constructing a new plant that included a mechanical repair facility, which required the installation of an overhead crane. The customer provided a reference photo and clearly specified their requirements for both the crane and the supporting steel structures.

Our technical team completed a tailored design within just one day, and we promptly sent the customer the drawings and a quotation. The customer was very satisfied with our solution. From July to September, we communicated via email to finalize all project details, and eventually signed a contract.

Project Details:

- Crane Type: European-Type Single Girder Overhead Crane with Steel Structures

- Crane Span: 10.4 meters

- Lifting Height: 5.32 meters

- Total Travel Length: 41.2 meters

1-Ton Free Standing Workstation Bridge Crane for U.S. Customer

This project marked one of the fastest orders we’ve received from an American customer. I still clearly remember receiving the urgent inquiry requesting a quote for an overhead crane.

The customer needed a crane for their existing workshop to lift machine spare parts. To provide an accurate solution, we had to confirm several key parameters: span length, maximum lifting capacity, crane travel distance, and most importantly, the available space within the workshop.

Thanks to the customer's prompt cooperation, we finalized the specifications after about seven days of continuous communication. The confirmed order details are as follows:

- Lifting Capacity: 1 ton

- Lifting Height: 5.1 meters

- Span Length: 4.88 meters

- Quantity: 3 sets

Light Duty Overhead Crane FAQ

What is the ASME standard for overhead cranes?

The ASME standard that applies to overhead cranes is ASME B30.2 – Overhead and Gantry Cranes (Top Running Bridge, Single or Multiple Girder, Top Running Trolley Hoist). This standard outlines the design, inspection, maintenance, testing, and operation requirements for overhead and gantry cranes in the United States.

ASME B30.2 helps ensure that overhead crane systems, including light duty bridge cranes, operate safely and efficiently. If you're purchasing a crane for use in a region that follows ASME standards, it's important to ensure your equipment complies with these guidelines.

DGCRANE offers customizable crane solutions that can be designed to meet ASME B30.2 or other international standards based on your project needs.

What is the duty classification of a crane?

The duty classification of a crane refers to the grading system that defines how intensively a crane can be used, considering factors like load capacity, frequency of operation, and working environment. According to the Chinese national standard GB/T 3811-2008 for overhead cranes, there are eight duty classes—A1 to A8—with A1 being the lightest and A8 the heaviest-duty.

For example, light duty overhead cranes or light duty bridge cranes typically fall within the A1–A3 range, meaning they are designed for intermittent use, lower loads, and non-continuous operation—ideal for maintenance workshops, light assembly lines, or warehouses.

What are heavy duty cranes used for?

Heavy duty cranes are designed to handle high-frequency, continuous operation with heavy loads in demanding industrial environments. These cranes typically fall into higher duty classifications (such as A6 to A8), ensuring durability, safety, and reliability even under rigorous working conditions.

Common applications include steel mills, shipyards, heavy manufacturing, construction sites, and large logistics hubs where lifting heavy materials is frequent and critical.

For detailed information, you can explore our dedicated pages on Heavy Duty Overhead Cranes and Heavy Duty Gantry Cranes. These pages cover various types, specifications, pricing, and real-world project cases to help you select the best crane for your heavy lifting needs.

Conclusion

In summary, light duty overhead cranes (also known as light duty bridge cranes) offer an efficient, reliable, and cost-effective solution for lifting tasks with low frequency and lighter loads. Whether you need a standard model or a customized design, understanding the types, pricing factors, and proven DGCRANE project cases can help you make the right choice.

With over a decade of export experience and a strong commitment to quality and service, DGCRANE is your trusted partner for light duty crane solutions worldwide.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!