Indoor Workshop Overhead Cranes for Sale: Efficient Lifting for Factories & Warehouses

Table of Contents

Indoor workshop overhead cranes—also known as bridge cranes or EOT (Electric Overhead Traveling) cranes—are essential equipment in a wide range of industries, from manufacturing and warehousing to automotive and energy. These cranes are designed to maximize space efficiency, improve workflow, and ensure safe, precise lifting operations within indoor environments.

In this guide, we'll walk you through the different types of indoor workshop overhead cranes, provide insights on indoor workshop overhead crane pricing, and help you understand how to choose the right indoor crane for your specific facility needs. You'll also see real-world examples of how DGCRANE indoor workshop overhead cranes have been successfully implemented in various countries, reflecting our global reach and commitment to quality.

Whether you’re exploring a new installation or upgrading your current material handling system, DGCRANE delivers indoor crane solutions that balance durability, cost-effectiveness, and compliance with international standards. Our cranes are engineered for long-term reliability and tailored to meet the demands of modern production environments.

Indoor Workshop Overhead Crane Types

Single Girder Overhead Crane

Single girder overhead cranes are our most popular type of indoor workshop overhead crane, widely used in machining, assembly, equipment maintenance, warehousing, and other industrial applications. These indoor workshop overhead cranes offer a compact structure, excellent rigidity, flexible operation, and an attractive design. They are known for their safety and reliability, and are commonly used in combination with CD1 or MD1 electric hoists.

Key Specifications

- Standard Capacity: 1t/2t/3t/5t/10t/16t/20t or customized on demand

- Span length: 7.5m-31.5m

- Lifting height: 6m/9m/12m/18m/24m/30m

- Work duty: A3/A4

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

Applications

Single girder indoor workshop overhead cranes ideal for lifting tasks in automotive assembly, machining workshops, and general factory operations

More Types and Configurations

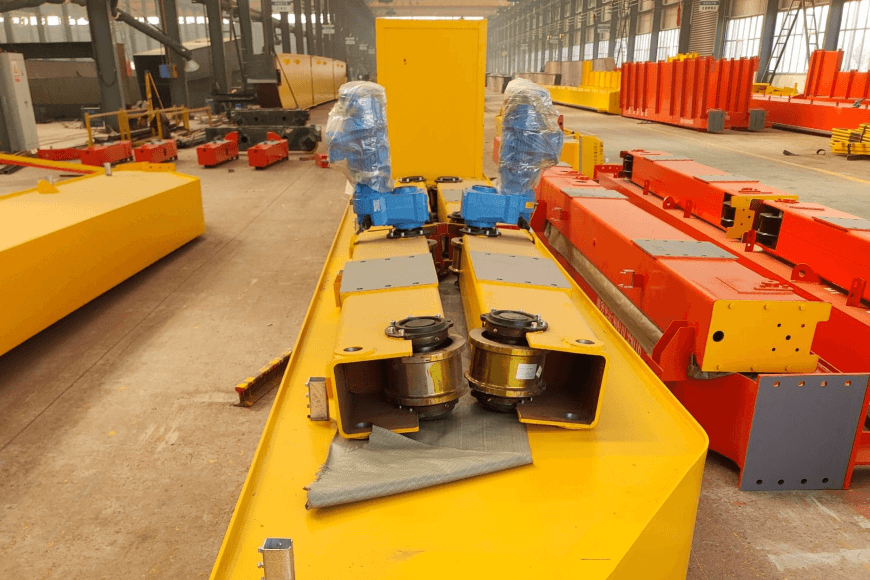

Double Girder Overhead Crane

The double girder indoor workshop overhead crane, with a lifting capacity of up to 800 tons and spans up to 34 meters, enables safe and precise handling of heavy loads. With various designs and spreaders, it can grab different materials, making it the most versatile heavy-duty crane across industries.

Key Specifications

- Capacity: 5-800/150ton

- Span length: 10.5-34m

- Lifting height: 12-50m

- Work duty: A5, A6

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Floor control / Remote control / Cabin room

Applications

Double-girder bridge cranes are widely used in various industries, including automotive, manufacturing, papermaking, steel, energy, warehousing, and more.

More Types and Configurations

Underslung Crane

Underhung cranes—sometimes referred to as underhung overhead cranes, under running overhead cranes. Underhung cranes are the choice when there is insufficient space in the upper part of the plant, or there is no conventional crane runway but the roof can be stressed.Under running cranes in standard capacities up to 10 tons.

Key Specifications

- Capacity: 0.5ton/1ton/2ton/3ton/5ton/10ton

- Span length: 5.5m-16.5m

- Lifting height: 6m/9m/12m/18m/24m/30m, manual type upto10m

- Work duty: A3/A4, manual type A1

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC / Manual Mode

- Crane control mode: Ground control / Remote control

Applications

The underslung crane is ideal for spaces with roof-mounted load-bearing structures and no floor columns, widely used in machining, assembly, repair, and warehousing.

Manual Overhead Crane

Manual indoor workshop overhead cranes are operated by human force and used for material handling in various industrial environments. With simple operation and minimal electrical components, they reduce maintenance costs and eliminate reliance on power supply. Ideal for areas without electricity or in potentially explosive environments where electrical equipment is unsuitable.

Key Specifications

- Capacity: 0.5ton/1ton/2ton/3ton/5ton/10ton

- Span length: 5m-14m

- Lifting height: 3~10m

- Work duty: A1

Application

Manual single-girder cranes are small and lightweight, suitable for factory equipment installation, maintenance, and workplaces without power or with frequent power outages. Manual monorail trolleys are compatible with these cranes and are highly adaptable.

Free Standing Workstation Overhead Cranes

Workstation overhead cranes are a kind of workstation bridge crane, also called freestanding overhead crane. The modular design makes installation and modular design of workstation overhead cranes makes installation and modification more convenient. The lower frictional resistance results in quieter and smoother operation.

Key Specifications

- Capacity: 125kg to 2000kg

- Work duty: M3, M4

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Floor control / Remote control

Features

- Reduced Building Cost: No need for factory brackets; lowers column load requirements and significantly reduces overall construction cost in early design stages.

- Minimal Equipment Idle Time: Precisely covers the needed working area, reducing waste from unused equipment.

- Modular Design: Easily expanded, disassembled, or relocated to meet evolving production needs without affecting other cranes in operation.

Applications

Freestanding workstation overhead cranes are ideal for industries like automotive, electronics, and warehousing. They support short-distance, frequent lifting in tight production spaces for tasks such as assembly, maintenance, and material handling.

Monorail Overhead Crane

Monorail overhead cranes usually refer to the type of overhead cranes where the main beam is a fixed I-beam and the hoist runs and lifts on the I-beam. These cranes can only move in two directions, in the vertical direction (up / down) or on the Y axis and in the horizontal direction along monorail beam or on the X axis. While single girder overhead crane able to move in three directions or more on the X, Y, Z axis and move radius in the vertical axis.

Key Specifications

- Capacity: 0.5ton/1ton/2ton/3ton/5ton/10ton

- Lifting height: 6m/9m/12m/18m/24m/30m

- Work duty: M3/M4

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Floor control / Remote control

Monorail overhead cranes are mostly used to relocate materials or products within a limited area. Monorail crane design is simple and can be compatible with the structure of the building without major changes.

Indoor Workshop Overhead Crane Price

The cost of an indoor workshop overhead crane depends on factors like capacity, span, and customization. At DGCRANE, we focus on delivering high-quality indoor cranes at competitive prices.

With efficient production and strict quality control, our cranes offer long-term performance and reliability—helping you save on maintenance and maximize value. Whether standard or custom, DGCRANE provides cost-effective solutions without compromising on safety or standards.

| Products | Span/m | Lifting Height/m | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 1 ton overhead crane | 7.5-28.5 | 6-30 | 220-480/3/50 | $1,830-5,100 |

| 2 ton overhead crane | 7.5-28.5 | 6-30 | 220-480/3/50 | $2,000-5,900 |

| 3 ton overhead crane | 7.5-37.5 | 6-30 | 220-480/3/50 | $2,130-15,760 |

| 5 ton overhead crane | 7.5-37.5 | 6-30 | 220-480/3/50 | $3,130-16,760 |

| 10 ton overhead crane | 7.5-37.5 | 6-30 | 220-480/3/50 | $3,890-20,000 |

| 16 ton overhead crane | 7.5-37.5 | 6-30 | 220-480/3/50 | $4,180-23,400 |

| 20 ton overhead crane | 7.5-37.5 | 6-30 | 220-480/3/50 | $7,100-28,600 |

| Capacity/t | Span/m | Lifting height/m | Lifting speed (m/min) | Price/$ |

|---|---|---|---|---|

| 5t | 10.5-31.5 | 16 | 12.5/15.5 | $15600-29500 |

| 10t | 10.5-31.5 | 16 | 8.5/3.2 | $17200-32500 |

| 16t/3.2t | 10.5-31.5 | 17/19 | Main hook 7.9/10.8 Aux. hook 11.2 |

$24200-42500 |

| 20t/5t | 10.5-31.5 | 12/14 | Main hook 7.2/9.7 Aux. hook 12.7 |

$25500-45900 |

| 32t/5t | 10.5-31.5 | 14/16 | Main hook 6/7.4 Aux. hook 12.5 |

$36200-59800 |

| 50t/10t | 10.5-31.5 | 12/16 | Main hook 5/6.1 Aux. hook 8.5 |

$49500-72000 |

| 75t/20t | 13.5-31.5 | 20/22 | Main hook 3.8/5 Aux. hook 7.2 |

$96000-136700 |

| 100t/20t | 13-31 | 18/20 | Main hook 3.1/3.9 Aux. hook 7.2 |

$115000-166700 |

| 200t/50t | 13-31 | 20/22 | Main hook 2.6 Aux. hook 7.7 |

– |

| 300t/75t | 13-31 | 24/26 | Main hook 2.4 Aux. hook 6.8 |

– |

| 400t/80t | 13-31 | 23/25 | Main hook 2.6 Aux. hook 5.1 |

– |

| 500t/100t | 13-31 | 20/22 | Main hook 2 Aux. hook 4.7 |

– |

| 600t/150t | 34 | 24/26 | Main hook 0.17-1.7 Aux. hook 0.41-4.1 |

– |

| 800t/150t | 34 | 26/28 | Main hook 0.15-1.5 Aux. hook 0.41-4.1 |

– |

| Capacity/t | Span/m | Lifting height/m | Lifting speed (m/min) | Working duty | Total power/kW | Price($) |

|---|---|---|---|---|---|---|

| 5t | 10.5-31.5 | 16 | 12.5/15.5 | A5,A6 | 22.8-27.8 | $15600-29500 |

| 10t | 10.5-31.5 | 16 | 8.5/3.2 | A5,A6 | 26.8-34.8 | $17200-32500 |

| 16t/3.2t | 10.5-31.5 | 17/19 | Main hook 7.9/10.8 Aux. hook 11.2 |

A5,A6 | 48.9-55.3 | $24200-42500 |

| 20t/5t | 10.5-31.5 | 12/14 | Main hook 7.2/9.7 Aux. hook 12.7 |

A5,A6 | 55.6-69 | $25500-45900 |

| 32t/5t | 10.5-31.5 | 14/16 | Main hook 6/7.4 Aux. hook 12.5 |

A5,A6 | 71.3-86.3 | $36200-59800 |

| 50t/10t | 10.5-31.5 | 12/16 | Main hook 5/6.1 Aux. hook 8.5 |

A5,A6 | 93.5-110.5 | $49500-72000 |

| 75t/20t | 13.5-31.5 | 20/22 | Main hook 3.8/5 Aux. hook 7.2 |

A5,A6 | 128-158 | $96000-136700 |

| 100t/20t | 13-31 | 18/20 | Main hook 3.1/3.9 Aux. hook 7.2 |

A5,A6 | 136-174 | $115000-166700 |

| 200t/50t | 13-31 | 20/22 | Main hook 2.6 Aux. hook 7.7 |

A5 | 239-279 | – |

| 300t/75t | 13-31 | 24/26 | Main hook 2.4 Aux. hook 6.8 |

A5 | 485-537 | – |

| 400t/80t | 13-31 | 23/25 | Main hook 2.6 Aux. hook 5.1 |

A5 | 608-640 | – |

| 500t/100t | 13-31 | 20/22 | Main hook 2 Aux. hook 4.7 |

A5 | 699-735 | – |

| 600t/150t | 34 | 24/26 | Main hook 0.17-1.7 Aux. hook 0.41-4.1 |

A5 | 466 | – |

| 800t/150t | 34 | 26/28 | Main hook 0.15-1.5 Aux. hook 0.41-4.1 |

A5 | 588 | – |

The cost of an indoor workshop overhead crane depends on several key factors, including lifting capacity, span, working environment, and customization needs. Due to these variables, any pricing listed is for general reference only.

For a precise quotation based on your specific requirements, we recommend contacting DGCRANE directly. With a focus on quality, efficiency, and value, DGCRANE delivers reliable indoor workshop overhead crane solutions at highly competitive prices, tailored to projects around the world.

How to Choose the Right Indoor Workshop Overhead Crane for Your Facility

Choosing the right indoor workshop overhead crane requires a careful assessment of your facility's structural conditions, lifting requirements, and operational needs. Factors such as lifting capacity, span, building height, and frequency of use all play a key role in determining the most suitable crane solution.

Each indoor workshop overhead crane type has its own strengths and limitations. Some are better suited for heavy loads and high lifting heights, while others are optimized for compact spaces or cost-sensitive operations. Understanding these trade-offs is essential to achieving long-term efficiency and safety.

With deep industry experience, DGCRANE provides tailored guidance to help you select the most appropriate indoor workshop overhead crane configuration—balancing performance, space, and budget to match your specific application.

| Indoor Crane Types | Pros | Cons |

| Single Girder Overhead Crane |

|

|

| Double Girder Overhead Cranes |

|

|

| Underslung Cranes |

|

|

| Manual Overhead Cranes |

|

|

| Workstation Overhead Cranes |

|

|

| Monorail Overhead Cranes |

|

|

Understanding each indoor workshop overhead crane type's strengths and limitations will help you make the best choice for your facility.

For many facilities, one of the most important decisions is choosing between a single girder and a double girder overhead crane. Each offers unique advantages depending on your lifting needs, budget, and building constraints. To better understand the differences and make an informed decision, check out our in-depth guide: Single Girder vs. Double Girder Overhead Cranes – Which Is Right for You?

If you’re unsure which indoor workshop overhead crane is the best fit for your facility, DGCRANE is here to help. With years of experience in crane design, manufacturing, and global installation, our team can provide expert advice and customized solutions tailored to your specific needs.

Contact DGCRANE today to get professional support, technical guidance, and a competitive quote for your indoor crane project.

Indoor workshop Overhead Crane – DGCRANE Overseas Project Cases

With over 10 years of export experience, DGCRANE has become a trusted global supplier of indoor workshop overhead cranes. Our products have been successfully delivered and installed in more than 120 countries, covering a wide range of industries—from manufacturing and logistics to steel, energy, and beyond.

Backed by deep technical expertise and a strong commitment to customer service, DGCRANE provides reliable crane solutions tailored to local standards, working conditions, and operational needs. Whether it’s design, production, or after-sales support, we ensure smooth project delivery and long-term satisfaction for clients around the world.

Here are some of our representative indoor workshop overhead crane projects from around the world, showcasing DGCRANE's capability to deliver reliable, customized solutions across different industries and environments.

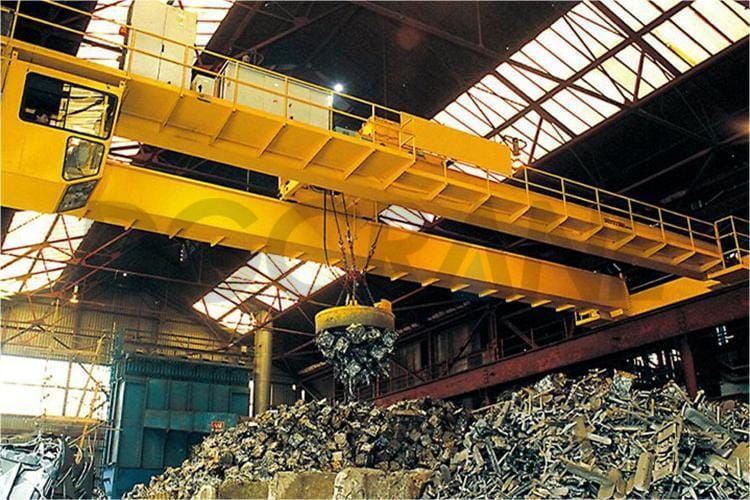

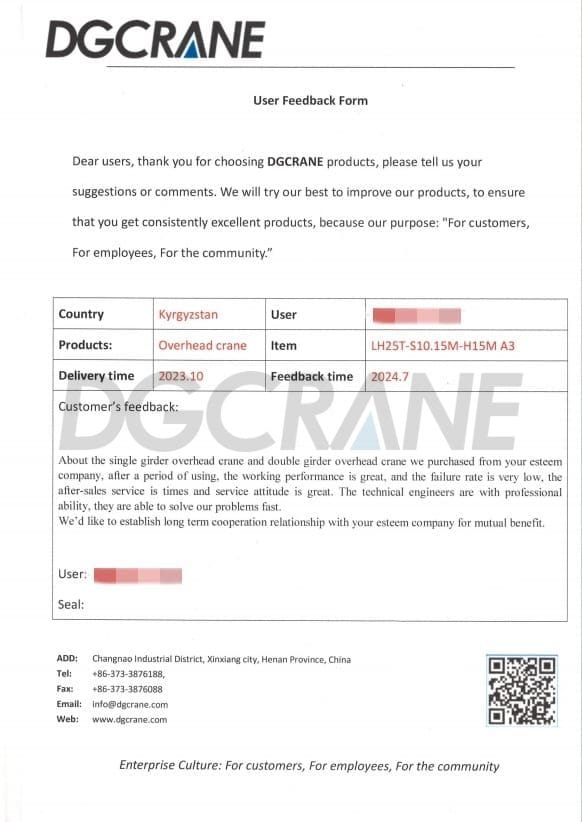

25t Double Girder Overhead Crane Installed in Kyrgyzstan

The project is used for the customer's newly designed power house for hydro power plant.

The double girder overhead crane installation was completed in January 2024 after the customer received the goods in November last year. After a period of use, customers are very satisfied with our products.

- Lifting capacity:25t ;

- Span length:10m;

- Lifting height:14m ;

- Working class: A3

- Industrial voltage: 380V/50Hz/3Ph

- Lifting speed: 0.22/2.2m/min (Double Speed)

- Trolley traveling speed: 20m/min

- Crane traveling speed: 20m/min

- Crane control mode: Pendant panel+Wireless remote control

We are very happy with the customer's recognition of our products. Here is the positive feedback from our customers:

1 Ton Freestanding Bridge Crane Sold to USA Customers

The customer want to build an overhead crane in the existing workshop to lift machine spare parts, so we have to clarify the span length, maximum lifting capacity, crane traveling length etc parameters, especially have to know the available space in the workshop.

LD model USA single girder overhead cranes with whole steel support structure.

- Lifting capacity: 1t

- Lifting height: 5.1m

- Span length: 4.88m

- Quantity: 3 sets

- 1 Ton Freestanding Bridge Crane Price: 90000 RMB

Installation and Test Run of 16-Ton Overhead Cranes in Tanzania

According to the customer's requirements, we arranged for an engineer to go to the customer's site to guide the installation of the crane. We arrived at the customer's site on July 16th and returned to our factory on August 29th. Here are some product and installation pictures.

Type 1: Single Girder Overhead Crane

- Capacity: 16ton

- Crane Span: 20 m

- Lifting height: 7.8m

- Work class: ISO A3;

- Control mode: Pendant control

- Power source: 380V/50Hz/3Ph (48V)

Type 2: NLH European type Double Girder Overhead Crane

- Capacity: 16ton

- Crane Span: 20 m

- Lifting height: 8.5 m

- Work class: ISO A3;

- Control mode: Pendant Control

- Power source: 380V/50Hz/3Ph (48V)

Indoor workshop Overhead Crane FAQ

What are the main types of indoor cranes?

Indoor cranes generally fall into three main categories:

Indoor workshop Overhead Cranes (Bridge Cranes / EOT Cranes) – Installed on building structures, suitable for wide-span and high-efficiency lifting tasks.

Indoor Gantry Cranes – Supported by legs and run on ground rails, ideal for areas without suitable overhead support.

Indoor Jib Cranes – Feature a rotating arm, commonly used for localized, flexible lifting in workstations or production lines.

Each type serves different operational needs depending on the facility layout and load requirements.

What are the 4 types of overhead cranes?

The four main types of overhead cranes are:

Bridge Cranes – Also known as EOT cranes, these indoor workshop overhead cranes run on tracks mounted to the building's structure, making efficient use of overhead space for lifting and transporting loads.

Gantry Cranes – Similar to bridge cranes but supported by legs running on rails or wheels, often used where overhead structures are not available.

Jib Cranes – Feature a rotating arm (jib) mounted on a wall or floor pillar, commonly used for localized lifting.

Monorail Cranes – Operate on a single beam or track, suitable for linear or curved paths in production lines.

Each type offers unique benefits depending on the specific application and workspace layout.

Conclusion

Indoor workshop overhead cranes are essential for improving efficiency, safety, and material handling workflows in industrial environments. Selecting the right type and specifications requires careful consideration of your operational needs, facility layout, and budget.

With over 10 years of export experience and installations in more than 120 countries, DGCRANE is a trusted global supplier of high-quality, cost-effective indoor crane solutions. From consultation and design to manufacturing and after-sales support, we're dedicated to delivering reliable equipment and exceptional service.

Contact us today to find the ideal indoor workshop overhead crane for your facility.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!