-

INDUSTRIES

-

Precast Concrete Plant

-

Steel Industry

-

Paper Industry

-

Waste to Energy and Biomass Industry

-

Power Industry

-

Overhead Cranes for Automotive Production: Smart Solutions for Enhanced Efficiency

-

Port Machines Industry

-

Manufacturing Industry

-

Different Types of Container Cranes, Shipyard Cranes, Cargo Cranes Used in Port, Harbor and Quay

-

Overhead Cranes for Timber Lifting: Efficient and Safe Wood Handling

-

Overhead Cranes for the Aviation Industry: Streamlining Aircraft Assembly, Maintenance, and Repair

-

Overhead Cranes for Food and Beverages: Ideal for improving productivity and food safety

-

Overhead Cranes for Aerospace Industry: Key Role in Efficient Rocket Manufacturing and Launch

-

-

EQUIPMENT

-

Overhead Cranes

-

Single Girder Overhead Crane

-

Double Girder Overhead Crane

-

Underslung Cranes

-

Workstation Overhead Cranes

-

Low Headroom Overhead Cranes

-

Grab Bucket Overhead Crane

-

Electromagnetic Overhead Cranes with Lifting Magnet

-

Electromagnetic Overhead Cranes with Magnet Beam

-

Manual Overhead Cranes

-

Double Trolley Overhead Cranes

-

LDP Single Girder Overhead Cranes

-

- Eot Cranes

- Gantry Cranes

- Jib Cranes

- FEM Standard Crane & Hoist

- Hoist & Winch Trolley

-

Light Cranes

-

Portable Mobile Gantry Cranes

-

Adjustable Gantry Cranes

-

Aluminum Gantry Crane

-

Foldable Aluminum Gantry Crane

-

Monorail Overhead Cranes

-

Workstation Jib Cranes

-

Electric Hoists

-

Workstation Overhead Cranes

-

Freestanding Workstation Bridge Crane

-

Ceiling Mounted Workstation Bridge Crane

-

Manual Portable Gantry Crane

-

Multi-point Suspension Cranes

-

- Explosion Proof Cranes and Hoists

-

Special Cranes

-

35-65t Clamp Overhead Crane

-

Boat Hoists

-

Boat Jib Crane

-

Yacht Davit Crane

-

Rail Mounted Container Gantry Crane

-

Cleanroom Overhead Cranes

-

YZ Ladle Handling Cranes

-

LDY Metallurgical Single Girder Crane

-

Charging Cranes for Steel Production

-

Insulated Overhead Cranes

-

Gantry Crane for Subway and Metro Construction

-

Forging Crane

-

Quenching Overhead Crane

-

Baking Multifunctional Crane

-

- Port Cranes

- Electric Transfer Carts

-

Overhead Cranes

-

CRANE PARTS

- Crane Wheel Range

- Crane Spreader

- Crane Drives

-

Crane Electrical Equipment

-

Overload Limiter

-

Crane Cabin

-

Crane Power Supply System

-

Explosion Proof Crane Radio Remote Controls

-

Joystick Type Crane Radio Remote Controls

-

Pushbutton Type Crane Wireless Remote Controls

-

Single-pole Insulated Conductor Rails

-

Enclosed Conductor Rails

-

Seamless Conductor Rails

-

Copperhead Conductor Rails

-

Overhead Crane Cables

-

- Other Cranes Parts

\

- ABOUT US

- CONTACT US

Introduction

Cranes play a vital role in numerous industries, enabling the lifting and transportation of heavy loads with precision and efficiency. They are divided into different types, including light cranes, overhead cranes, gantry cranes, and jib cranes. However, just like any other piece of machinery, cranes have a limited lifespan. The questions we get a lot are like”How long will my crane last?” or”Should I replace my crane or have maintenance?”

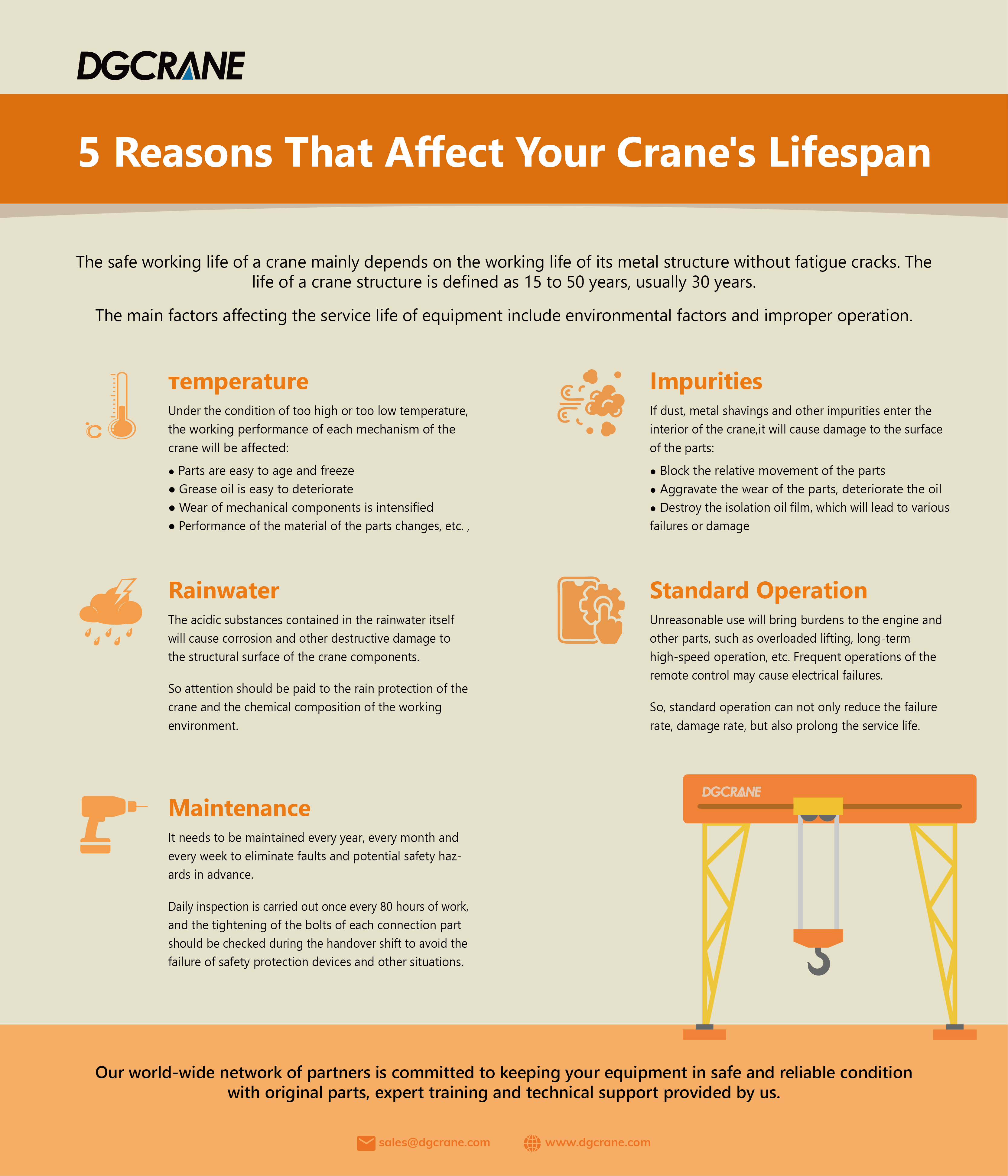

So firstly, here is an infographic to quickly answer your question about the lifespan of cranes and show you the 5 key reasons that affect it.

How long can a typical crane last? When should I replace my crane?

The lifespan of a crane refers to the period during which it remains functional, efficient, and safe to operate. When the crane cannot operate safely or functionally, it may need maintenance. The safe working life of a crane mainly depends on the working life of its metal structure without fatigue cracks. The life of a crane structure is defined as 15 to 50 years, usually 30 years. But when the cost to fix or maintain it outweighs the costs and benefits of replacement, it is the economic end of its life. You need a replacement then.

Taking the Overhead Crane Lifespan as an example, it generally varies in the Working Class. The lifespan of working class A1-A2 is 30 years, A3-A5 is 25 years, A6- A7 is 20 years. Another example is Gantry Crane. The lifespan of gantry cranes is usually 10 to 15 years. Besides, heavy duty cranes always lift large loads, making metal structures and stressed parts more likely to deform and crack. The lifespan of special cranes like Metallurgical Cranes, is shorter, generally 10-15 years, with maintenance and inspections. However, due to various reasons, these may be different in practice.

Aspects Influencing the Lifespan of Cranes

Crane life expectancy influenced by many aspects, including:

- Quality of Construction and Materials:

The construction quality and materials used in manufacturing a crane are crucial determinants of its life expectancy. Cranes built with high-quality components and robust materials are generally more durable and long-lasting. Components such as the boom, mast, cables, and control systems should be carefully inspected for quality before purchasing a crane. - Environmental Conditions:

The environmental conditions in which a crane operates can have a substantial impact on its lifespan. Extreme temperature, humidity, corrosive substances, and exposure to harsh weather elements can accelerate the wear and deterioration of crane components. Protective measures, such as anti-corrosion coatings and regular cleaning, should be employed to mitigate the effects of adverse environmental conditions. - Regular Maintenance and Inspections:

Regular maintenance and inspections are paramount to maximizing the lifespan of a crane. Routine inspections help identify any signs of wear and tear, damage, or malfunctioning components. Proper lubrication, alignment adjustments, and timely repairs should be carried out to prevent minor issues from escalating into major problems. - Operator Training and Competence:

The competence and training of crane operators significantly impact the lifespan of the equipment. Well-trained operators are more likely to operate cranes within their specified limits, avoiding undue stress on the machinery. Additionally, operators should adhere to recommended operational procedures and safety guidelines to minimize the risk of accidents and potential damage to the crane.

DGCRANE’s Team flew to Qatar to Provide Support Service

DGCRANE’s Team flew to Qatar to Provide Support Service

Among those aspects, environmental conditions and improper operation are the main aspects, and 5 key reasons of them (showed in the infographic) are most noticed.

Conclusion

In conclusion, crane life expectancy can be significantly extended through careful consideration of various factors. Investing in high-quality construction, implementing regular maintenance and inspections, prioritizing operator training, protecting against adverse environmental conditions, and considering upgrades and modernization can all contribute to maximizing the lifespan of cranes.

DGCRANE is a crane specialist. According to your specific need, we provide BUT are not limited to:

- High-quality cranes

- Professional operator training

- Guidance of our expert

- Various crane parts

- Exceptional after-sales maintenance

DGCRANE’s Crane Wheels (Click Here to Know More)

DGCRANE’s Crane Wheels (Click Here to Know More)

Choosing DGCRANE means that your cranes remain reliable and efficient, ultimately saving costs and improving operational productivity. For more information about cranes and crane parts, check out our homepage or speak to our experts.

CONTACT US to get the tailor-made solution for you NOW!

Zora Zhao

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

With 10+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

WhatsApp: +86 189 3735 0200

Email: zorazhao@dgcrane.com

Related Blogs

Subscribe to our newsletter

The latest DGCRANE price list, news, articles, and resources.

- Overhead Cranes

- Low Headroom Overhead Cranes

- Double Girder Overhead Crane

- Grab Bucket Overhead Crane

- Top Running Overhead Crane: Wide Application and Easy Maintenance

- Coker Cranes for Harsh Environments: High Temperature and Corrosion Resistant Design

- Overhead Cranes for Concrete Pile Precast Workshop: Versatile Solutions for Demanding Operations

- Single Girder Overhead Cranes

- Single Girder Eot Cranes

- Double Girder Eot Cranes

- Underslung Cranes

- Light Cranes

- Adjustable Gantry Cranes: Easy to Move, Safe, and Space-Efficient

- Foldable Aluminum Gantry Crane: Lightweight, Strong, and Portable

- Freestanding Workstation Bridge Crane: Lightweight, Modular and Adaptable Material Handling Solution

- Ceiling Mounted Workstation Bridge Crane: Ideal for Tight Spaces and Complex Layouts

- Multi-point Suspension Cranes: Suitable for Large-Span Industrial Workshop

- Manual Portable Gantry Crane: Cost-effective & Flexible for Light Lifting

- Workstation Overhead Cranes

- Monorail Overhead Cranes

- Workstation Jib Cranes

- Electric Hoists

- Shipyard Gantry Cranes: Specialized Lifting Solutions for Shipyard Operations

- Truss Gantry Cranes: Cost-Effective, Wind-Resistant, and Perfect for Large Spans

- FEM Double Girder Gantry Crane with Open Winch: European Performance, 20% Cost Saving

- Different Types of Small Portable Aluminium Gantry Cranes: Cost Effective

- Single Girder Gantry Cranes

- Double Girder Gantry Cranes

- Semi Gantry Cranes

- Casting Yard Gantry Cranes

- Container Gantry Cranes: RTG & RMG Solutions for Ports and Terminals

- Portable Mobile Gantry Cranes: Flexible, Movable and Space-Saving

- FEM Standard Crane & Hoist

- FEM Standard Overhead Cranes

- FEM Standard Gantry Cranes

- FEM Standard Jib Cranes

- FEM Standard Wire Rope Electric Hoists

- FEM Standard Electric Chain Hoists

- Hoist & Winch Trolley

- Low Headroom Wire Rope Electric Hoist: Compact Design for Efficient Lifting in Tight Spaces

- Electric Hoist for Molten Metal: High-Temperature, Safe Lifting for Metallurgical Environments

- Pneumatic (Air) Chain Hoists: Ideal for Explosion-Proof Environments

- Lever Hoists: Compact, Versatile Manual Lifting Tool

- Galvanizing & Pickling Electric Hoist for Harsh Environments

- 6 Double Girder Trolley Electric Hoists for Overhead Cranes: Custom Solutions for Every Lifting Need

- Manual Chain Hoists: Alloy Steel Construction for Smooth and Safe Lifting

- Electric Wire Rope Hoists

- Chain Hoists

- Crane Trolley

- Electric Winch

- Explosion Proof Cranes and Hoists

- Explosion Proof Single Girder Overhead Cranes: Safe Lifting Solution for Hazardous Environments

- Explosion Proof Wire Rope Electric Hoist: Upgrade Your Safe

- Explosion Proof Electric Chain Hoist of High Qualit

- Explosion Proof Manual Chain Hoist: Safety in Every Lift

- Explosion Proof Double Girder Overhead Crane: More Cost Effective

- Port Cranes

- Rubber Tyred Container Gantry Crane

- Ship To Shore Crane

- Container Straddle Carrier

- Harbour Portal Crane

- Shipyard Portal Cranes

- Container Gantry Cranes: RTG & RMG Solutions for Ports and Terminals

- Reliable Versatile Electric Transfer Carts

- AGV Transfer Carts

- Powerful Heavy Duty Coil Transfer Carts

- RGV Transfer Carts

- Powerful Pallet Transfer Carts

- Trackless Transfer Carts

- Reliable Heavy Duty Ladle Transfer Cars

- Superior Die Transfer Carts

- Rail Transfer Carts

CRANE PARTS

- Baking Multifunctional Crane: Furnace Tending Assembly for Efficient Carbon Roasting

- Segment Handling System for Concrete Segments in Shield Tunnel Construction

- Subway Track Laying Gantry Crane for Tunnel Track Installation

- Intelligent Film Roll Handling Overhead Crane for Roll Changing, Stacking, and Warehousing

- Intelligent Loading Overhead Crane: Reduce Labor Costs and Improve Loading Efficiency

- Automated Steel Plate Handling Overhead Crane: Applications in Steel Storage & Warehouse Operations

- Straightener Roll Changing Overhead Crane: Automated Roll Handling for Straightening Machines

- High-Temperature Slab Handling Overhead Crane: Continuous Casting and Slab Yard Operations

- Automated Bulk Grab Overhead Crane: Efficient Ore, Coal, Sand, and Slag Handling

- Electrolytic Copper Cranes: Cathode and Anode Handling in Copper Electrolysis Lines

- Pot Tending Machine: Specialized Equipment for Electrolytic Aluminum Production

- Anode Carbon Block Stacking Overhead Crane for Aluminum Electrolysis Plants

- Heavy Duty Forging Cranes: Durable, High-Capacity Solutions for Forging

- Quenching Overhead Crane for Heat Treatment Plant: High-Temperature Insulated and Efficient Lifting Solution

- Gantry Crane for Subway and Metro Construction: Efficient Tunnel Debris Removal Solutions

- Insulated Overhead Cranes for Safe Non-Ferrous Metal Smelting

- Charging Cranes for Steel Production: Safe and Reliable Solutions for Efficient Material Handling

- Cleanroom Overhead Cranes: Reliable Solutions for Healthcare, Electronics, and GMP Workshops

- Rail Mounted Container Gantry Crane

- Special Cranes

- 35-65t Clamp Overhead Crane

- Boat Jib Crane

- Yacht Davit Crane

- Boat Hoists

INDUSTRIES

- Steel Industry

- Paper Industry

- Power Industry

- Overhead Cranes for Automotive Production: Smart Solutions for Enhanced Efficiency

- Port Machines Industry

- Manufacturing Industry

- Overhead Cranes for Timber Lifting: Efficient and Safe Wood Handling

- Overhead Cranes for the Aviation Industry: Streamlining Aircraft Assembly, Maintenance, and Repair

- Overhead Cranes for Food and Beverages: Ideal for improving productivity and food safety

- Overhead Cranes for Aerospace Industry: Key Role in Efficient Rocket Manufacturing and Launch

- Precast Concrete Plant

- Waste to Energy and Biomass Industry

- Different Types of Container Cranes, Shipyard Cranes, Cargo Cranes Used in Port, Harbor and Quay

COMPANY

- sales@dgcrane.com

- +86 373 387 6188

- +86 189 3735 0200

- Floor 30,Gongyuan INT'I Building, Jinsui Road, Xinxiang City, Henan Province, China