Gantry Cranes in Bridge Construction: Innovative Applications and Expert Installation Insights

Table of Contents

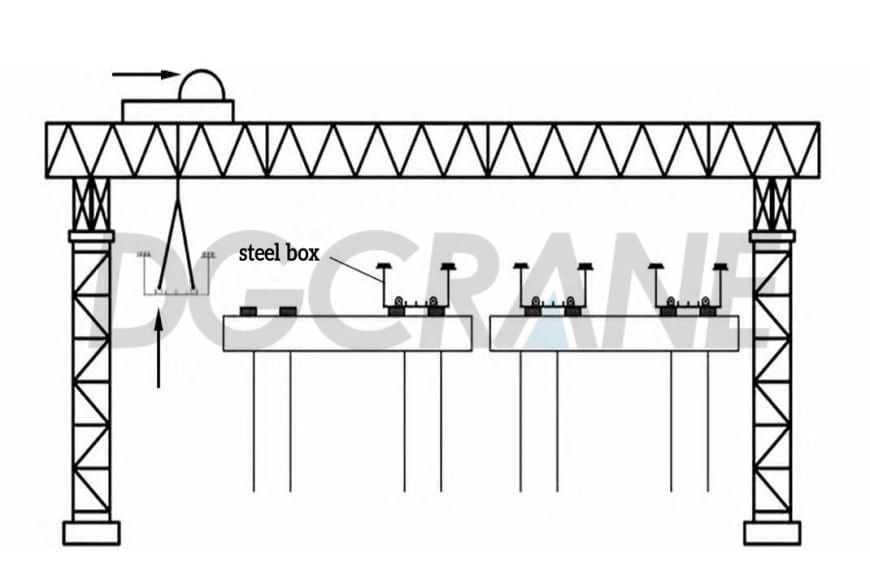

With the improvement of domestic construction enterprises’ capabilities in highway and railway bridge construction, China’s bridge construction projects are showing a trend of larger spans and higher construction difficulty, which puts forward higher requirements for bridge construction technology. During bridge construction, most medium and large components rely on gantry cranes for lifting operations. Therefore, reasonable installation of gantry cranes according to construction requirements can effectively improve equipment performance and bridge construction efficiency, as well as reduce construction costs.

Structure and Functions of Gantry Cranes

The structures of gantry cranes vary. Common basic components include the hoisting system, gantry frame, rail foundation, and trolley traveling system.

Hoisting System

The hoisting system is mainly used to lift or lower components with two lifting points. It consists of the tilting motor, main motor, planetary reducer, and drum. To ensure lifting balance, gantry cranes are usually designed with more than two hoisting systems. In order to stabilize the lifted object, the gantry crane needs to use the spreader beam and hoisting system to bear the load together, and then lift the component through the hydraulic crane or electric winch of the gantry crane.

Main Gantry Frame

The main gantry frame is the major structure of the gantry crane equipment and serves as the “stabilization system” of the crane, with the main function of ensuring lifting stability during operation. It is composed of a composite structure made of the main load-bearing beam and high/low-leg columns. The main beam is assembled by cross-joining many 65-pier bearing beams, with every two pieces fixed at the top of the support columns. Its main function is to ensure the stability of the gantry crane, rather than directly bearing the lifting load.

The main beam is generally a detachable truss beam or a multi-piece single-layer beam installed at the gantry position. The high and low-leg columns are also assembled from 65 piers, forming a multi-row column structure in both horizontal and vertical directions. Between the columns, horizontal bracing and cross diagonal bracing structures are installed. Adjacent columns on one side are reinforced with angle steel, and I-beams on top and bottom are reinforced with scissor bracing.

Rail Foundation

For bridge construction, gantry cranes are installed densely, and the wheels bear heavy pressure. Therefore, strict requirements are placed on the bearing capacity of the rail foundation. The foundation needs to be specially reinforced to withstand the rated load as per the gantry crane lifting design standards. Usually, the foundation is constructed as a reinforced concrete trough bed to ensure the rail base is solid and that the track’s smoothness meets design requirements.

Trolley Traveling System

The trolley traveling system ensures the safety and stability of lifting operations and is controlled by an electronic variable frequency speed controller. It is paired with pulleys and a slow-speed winch to reduce the impact caused by the sudden stopping or starting of the traveling device. To enable lateral movement, each trolley must be equipped with at least two pairs of steel wheels at the position of the main beam. The trolley traveling system typically consists of a track cart and a running rail.

Main Traveling System

For medium and large-scale bridge construction, conventional gantry crane traveling systems usually cannot meet construction requirements. A larger traveling system is needed. The main traveling system consists of a driving system and a traveling carriage, where the traveling carriage is a key control system in lifting operations. Assuming a fixed load capacity for the traveling carriage, lifting capacity can be increased by increasing the number of carriages. The traveling carriage meets the design load and travel distance requirements of bridge construction and reduces impact on the crane.

Generally, 83-pier steel and long I-beams are used as the traveling steel beam, paired with multifunctional carts. According to construction needs, single-track or double-track designs can be adopted. To minimize the impact of long-distance travel, control can be achieved by gear reduction drive systems with frequency converters; if the travel distance is short, it can use anchor points and traction devices for movement.

Installation Procedures and Key Points of Gantry Cranes in Bridge Construction

Installation Procedures

The installation of gantry cranes in bridge construction follows the principle of top-to-bottom and main structure first, followed by auxiliary structures. The installation procedures are as follows:

- Treat the foundation for the gantry crane. This is the basic step in bridge lifting operations. Ensure the compactness and flatness of the foundation meet the lifting requirements.

- Lay the steel track and wooden sleepers for the gantry crane's lower carriage. Ensure the parallelism and smoothness of the tracks meet design requirements.

- Place the lower carriage on the steel track and adjust its level and traveling position.

- Install the gantry crane columns. After column assembly, install the top steel plate, and then connect and brace between columns.

- Hoist the main beam of the gantry crane. After hoisting the main beams into position, connect them horizontally.

- Lay the trolley rail and place the trolley on the rail.

- Assemble the hoisting system, lifting beam, spreader beam, and rotating device.

- Install and debug the lateral and longitudinal movement systems. The lateral system refers to the trolley system, and the longitudinal system refers to the lower carriage system.

- Install and debug the automated electrical control system, which is the command system for lifting operations and an important part of the crane.

- Install lifting slings, complete the full debugging and trial run of the gantry crane, and prepare for actual construction.

Installation Key Points

When applying gantry cranes to bridge construction, strict quality control must be exercised during installation to prevent unstable operation or unbalanced forces during lifting, which could affect operational safety and stability.

- Stability and smoothness are key points for both track and carriage installations and are the basis for smooth lifting operations.

- Before rail installation, ensure the accuracy of survey data and control the rail elevation, slope, and single-wheel travel distance within design limits. Any deviations will affect stable crane operation.

- Before carriage installation, ensure the main beam and travel rail are securely installed. Ensure absolute parallelism of track distance. Install stop devices at both ends to prevent derailment.

- During upper beam installation, ensure the center distance between support legs is accurate. Maintain balance during splicing, typically using pull ropes to ensure safe assembly.

- When installing high and low-leg columns, follow a top-to-bottom order and ensure firm connections. For low-leg installation, use upper guy wires to adjust and ensure verticality. Use guy wires of 15 mm diameter with a 45° angle to the legs for sufficient tensile strength.

- The winch must meet lifting and load-bearing requirements and be securely connected to the carriage to prevent accidents caused by loosening.

- After changing pulley groups, lock both ends of the wire rope to ensure safe and stable pulley operation.

- The automated electrical control system must be installed by certified professionals. It must undergo commissioning and trial testing and be put into use only after passing all standard tests.

Analysis of Gantry Crane Applications in Bridge Construction

Commissioning and Operation

Commissioning should begin by powering the system. Each lifting action should be tested without load, and any deviation corrected until all parameters meet design standards. Once complete, the no-load commissioning ends.

Trial operation is similar but performed under load. Once deviations are corrected and standards are met under load, hoisting begins. After calculating main beam lifting points and completing main beam assembly, test lifting should stop when the beam is raised 10–20 cm for a balance check. Adjust configurations to level the beam.

In addition, operators should inspect the binding condition of the lifting slings and pads. Adjust as needed to ensure the best performance during lifting operations.

Application in Bridge Construction

- Bridge Component Transportation: Gantry cranes transport components from the storage yard to the bridge site. Accurate operation is required to prevent damage during handling.

- Component Installation: Components are installed precisely at designated locations. High-precision positioning ensures structural accuracy and bridge safety.

- Old Bridge Demolition: Gantry cranes are used to dismantle old bridges. High speed and stability ensure efficient and safe operations.

- Material Supply: Gantry cranes deliver materials like mortar and cement to work areas, providing a solid construction foundation.

- Bridge Maintenance and Inspection: Cranes assist in replacing damaged parts and repairing the bridge. Flexibility and stability are crucial to ensure repair quality and safety.

Conclusion

Gantry cranes offer advantages such as high lifting capacity, convenient installation and disassembly, and safe and stable operation. Many large bridge components rely on them for lifting. Scientific installation of gantry cranes based on construction requirements improves equipment performance, enhances construction efficiency, and reduces costs.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!