Cantilever Gantry Crane Selection Guide: Matching the Right Crane to Your Site Needs

Table of Contents

Introduction

A cantilever gantry crane is a type of gantry or semi-gantry crane in which the main girder extends beyond the crane runway on one or both sides. This design allows the crane to handle materials outside the standard rail span, providing extra reach and operational flexibility without moving the entire crane.

Cantilever gantry cranes are commonly seen in ports, freight yards, factories, and other heavy material-handling environments where extended reach is required. It is important to note that the cantilever configuration is not a separate type of crane but rather a structural modification of a standard gantry crane.

In practice, it must comply with OSHA 1910.179, which regulates overhead and gantry cranes, and the ASME B30 series, which provides guidelines for crane design, construction, and safe operation. Therefore, understanding the cantilever’s role, sizing, and operational principles is essential for selecting the right crane for your worksite.

Understanding the Role of the Cantilever

The cantilever is the beam structure that extends outward from the main girder beyond the crane’s runway track. Its primary purpose is to expand the crane’s working range without modifying the rail layout.

More specifically:

- Expands the Working Range: By extending beyond the runway, the crane can cover a wider material-handling area and adapt flexibly to confined spaces.

- Improves Operational Efficiency: Reduces unnecessary repositioning, shortens handling time, and significantly boosts overall productivity.

- Offers Broad Applicability: With these advantages, cantilever gantry cranes perform effectively across ports, freight yards, factories, and other industrial environments.

In other words, by extending the main girder beyond the runway, the cantilever allows operations both inside and outside the span, improving productivity while minimizing repositioning or downtime.

Key Advantages of Cantilever Gantry Cranes

Building upon the role described above, the cantilever structure also brings clear operational advantages. Its functions can be summarized as follows:

- Lifting and Transporting Loads: The cantilever enables vertical lifting and horizontal movement to reach areas outside the normal rail span.

- Expanding the Working Range: Even in tight or restricted spaces, the cantilever makes it possible to cover a broader material-handling area.

- Improving Efficiency: Operations become faster because fewer repositionings are needed, and multiple lifts can often be performed within the same span.

Thanks to these benefits, cantilever gantry cranes are particularly suitable for ports, large factories, freight yards, and construction sites. By strategically extending the crane beyond the rails, operators can handle oversized or off-track materials without obstructing internal operations.

How to Determine the Right Cantilever Length

Once the role and advantages are clear, the next step is to determine how long the cantilever should be. Selecting the correct length is crucial for both safety and efficiency.

A general industry starting point is approximately one-third of the crane span. However, the final design must account for multiple factors:

- Structural Load and Self-Weight: Longer cantilevers increase the crane’s self-weight and stress on supports.

- Working Radius: Effective reach depends on the horizontal distance from the load support point to the outer edge of the main girder.

- Environmental Factors: Wind load, temperature extremes, high-altitude operation, and corrosive environments must all be considered.

- Operational Conditions: Load frequency, lifting height, hook approach, and site layout influence safe cantilever length.

In practice, typical cantilever lengths range between 6 and 12 meters, striking a balance between reach and structural integrity. For real-world projects, professional engineers should always perform calculations for stress, deflection, wheel load, and stability, verifying that the cantilever can safely operate under expected loads.

Design Flow for Cantilever Sizing:

- Define duty group and load spectrum (ISO/FEM/CMAA).

- Determine rated load and calculate load cases including dead, live, wind, and acceleration forces.

- Pre-size cantilever envelope based on hook reach and site clearance.

- Run structural checks: girder stress, deflection limits, wheel loads, and stability margins.

- Iterate until safety and operational requirements are satisfied.

Note: Any thumb-rule ratio (like one-third of span) is for preliminary screening only. The final cantilever length must always pass engineering calculations and safety verification.

Determining the right cantilever length requires more than rule-of-thumb calculations. DGCRANE’s professional engineers can provide customized structural analysis and selection advice based on your site conditions.

Contact DGCRANE Engineers, today for a tailored consultation and ensure your gantry crane is both safe and efficient.

Common Types of Cantilever Gantry Cranes

After determining the right cantilever size, the next consideration is the type of gantry crane configuration. Using a double-girder gantry crane as an example, the main categories are:

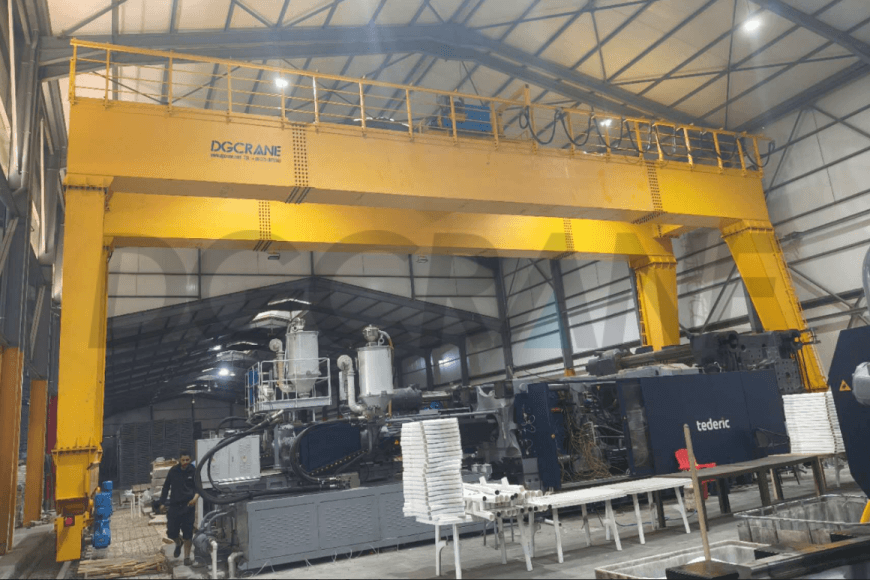

Single-Cantilever Gantry Crane: Features a cantilever on one side of the main girder.

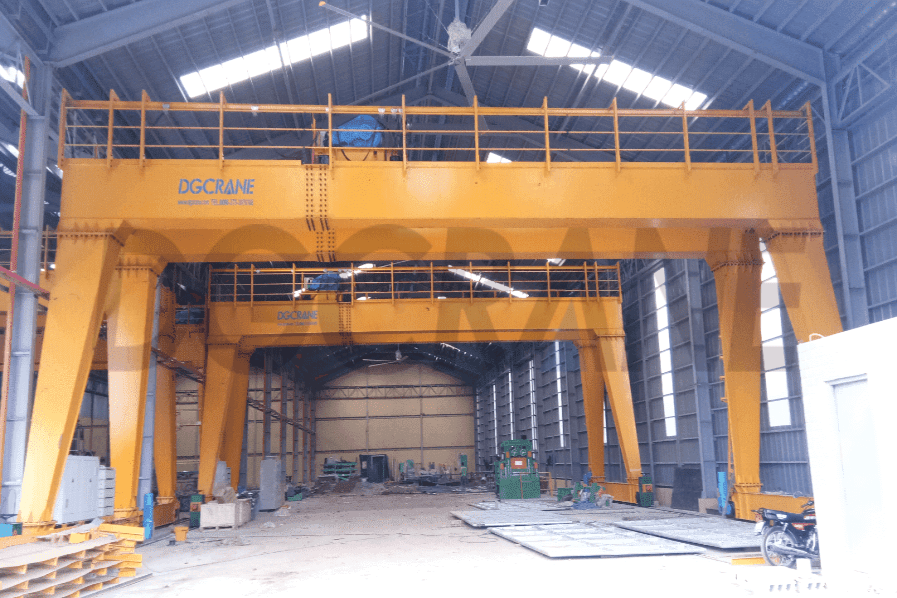

Double-Cantilever Gantry Crane: Features cantilevers on both sides of the main girder.

Non-Cantilever Gantry Crane: A design without any cantilever extension beyond the runway track.

In many projects, gantry cranes are designed with cantilever structures to expand the service area and meet specific cargo-handling requirements. Such designs not only fulfill operational needs but also optimize material use and reduce the crane’s self-weight.

Cantilever lengths may be equal or unequal, and a single cantilever can be adopted depending on the specific layout and requirements of the worksite. For general-purpose gantry cranes, however, the overall design most commonly adopts a double-cantilever configuration with equal or nearly equal lengths on both sides, ensuring balanced performance and efficient site utilization.

Comparison Overview:

| Type | Structure | Typical Application | Cost | Features |

|---|---|---|---|---|

| Single-Cantilever Gantry Crane | Extension on one side | Narrow warehouses, restricted areas | Moderate | Flexible in tight spaces, one-sided reach |

| Double-Cantilever Gantry Crane | Extensions on both sides | Ports, factories, large yards | Higher | Wide working area, balanced, stable |

| Non-Cantilever Gantry Crane | Girder flush with runway | Sites confined to span | Lower | Light, simple structure, limited working range |

Practical Guide to Selecting the Right Cantilever Gantry Cranes

With the above types in mind, the final step is to select the right configuration for your specific site. This involves careful consideration of site conditions, lifting requirements, and operational efficiency.

- Check Site Conditions – If space inside the span is sufficient, a non-cantilever crane is economical and simple.

- Identify Lifting Needs – For operations concentrated on one side (e.g., narrow aisles), a single-cantilever crane provides flexibility.

- Evaluate Load and Service Area Requirements – For a large working range, high capacity, and balanced stability, a double-cantilever crane is usually the best choice.

Other factors include rail gauge, foundation capacity, clearance, environmental conditions, and compliance with OSHA and ASME standards. A thorough assessment ensures the crane you choose will deliver safety, reliability, and efficiency.

Conclusion

Cantilever gantry cranes—whether non-cantilever, single-cantilever, or double-cantilever—each offer unique structural and operational advantages. Understanding the differences in weight, structure, application scenarios, cost, and performance is essential for selecting the most suitable type for your worksite.

By carefully assessing site conditions, lifting requirements, and operational efficiency goals, you can make the right choice between the three designs. With the proper selection, a cantilever gantry crane not only improves handling efficiency but also ensures safe, reliable, and cost-effective performance across diverse industrial environments.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!