5 Ton Jib Crane for Industrial Workshop Lifting Solutions

Table of Contents

5 ton jib cranes are versatile lifting solutions designed to improve material handling efficiency in a wide range of industrial environments. Depending on your workspace and operational needs, we offer three main types: pillar (freestanding) jib cranes for maximum flexibility, wall-mounted jib cranes for space-saving installation, and wall-traveling jib cranes for extended horizontal coverage. Each type can be customized to meet your specific lifting height, working radius, and installation conditions.

5 Ton Jib Crane Types

Free standing Jib Crane

Advantages:

- Flexible installation with 360° rotation

- High load capacity, suitable for high-frequency operations

- Typical industries: automobile manufacturing, metal processing, machinery assembly, and heavy industry

Application Scenarios:

- Spacious workshops or alongside production lines

- Independent work areas without walls or columns for mounting

- Assembly areas, equipment maintenance zones, and heavy material loading/unloading stations

Wall Mounted Jib Crane

Advantages:

- Saves floor space

- Easy installation with relatively low cost

- Typical industries: electronics manufacturing, equipment maintenance, and parts packaging lines

Application Scenarios:

- Workshop walls or columns are sturdy and offer sufficient installation height

- Areas with limited floor space where installing column-mounted equipment is impractical

- Near small assembly lines, maintenance benches, or workstations

Wall Traveling Jib Crane

Advantages:

- Can move horizontally along a track, offering wide coverage

- Ideal for continuous operations or multi-station material handling

Application Scenarios:

- Long and narrow workshops, production lines, or assembly lines

- Work areas requiring wide horizontal movement along the wall

- Operations with widely distributed lifting points and long transportation paths

How to Quickly Choose the Right Type of 5 Ton Jib Crane

Selecting the right jib crane depends largely on your installation site, lifting needs, and operational workflow. Here’s a quick guide to help you decide between the most common types:

| Type | Best For | Mounting Requirement | Rotation Angle | Key Benefits |

| Free standing Jib Crane | Open areas or where structural support isn't available | Requires a concrete foundation | Up to 360° | High flexibility and heavy-duty use |

| Wall-Mounted Jib Crane | Facilities with strong structural walls and limited floor space | Mounted directly on a structural wall | Up to 180° | Space-saving and economical |

| Wall-Traveling Jib Crane | Large workshops with long travel requirements along a wall | Requires a supporting runway on the wall | ————– | Extended coverage without floor obstruction |

Quick Tips:

- Choose freestanding if you need full rotation or have no structural support.

- Choose wall-mounted to save floor space in areas with strong support walls.

- Choose wall-traveling for long workstations requiring wide lateral movement.

Still unsure? Contact us—we'll help you assess your environment and recommend the most efficient and cost-effective jib crane solution for your needs.

5 Ton Jib Crane Price

The price of a 5 ton jib crane is not a fixed figure, as each system is custom-engineered to match specific working conditions and user requirements. Several factors influence the final cost, including lifting height, jib arm length, rotation angle, mounting type (freestanding, wall-mounted, etc.), control system, hoist configuration, and any special design needs such as explosion-proof or corrosion-resistant features.

Because of the high degree of customization involved, we provide tailored pricing based on your project specifications. By understanding your application and operational needs, our team can recommend the most efficient and cost-effective jib crane solution.

Looking for a reliable and competitively priced 5 ton jib crane? Get in touch with us today for a personalized quote and expert consultation.

5 Ton Jib Crane Cases

Discover how businesses across manufacturing, logistics, and heavy industry are using our 5 ton jib cranes to boost efficiency, ensure safety, and streamline material handling. Each project showcases the flexibility and reliability of our custom-engineered solutions.

5 Ton Free Standing Jib Crane for Sale to KSA

A client in the metal processing industry needed an efficient and reliable solution to lift heavy iron products in a sheltered working environment. Due to the long working radius required, we recommend our heavy-duty free standing jib crane, equipped with upper rotation via a slewing bearing for smooth and stable operation.

After installation, the crane performed exceptionally well, meeting the customer’s operational needs with high efficiency and durability. The client expressed great satisfaction with both the design and the overall quality of our product, highlighting the crane's stability, ease of use, and robustness in their daily operations.

This case reflects our commitment to delivering tailored lifting solutions that combine performance, safety, and long-term value.

Specification:

- Type: Free Standing Jib Crane

- Capacity: 5 ton

- Working radius: 13m

- Lifting height: 7m (6m above floor, 1m under floor)

- Rotate angle: 360°

- Control mode: Pendant control + Remote control

- Power source: 380V/60Hz/3Ph

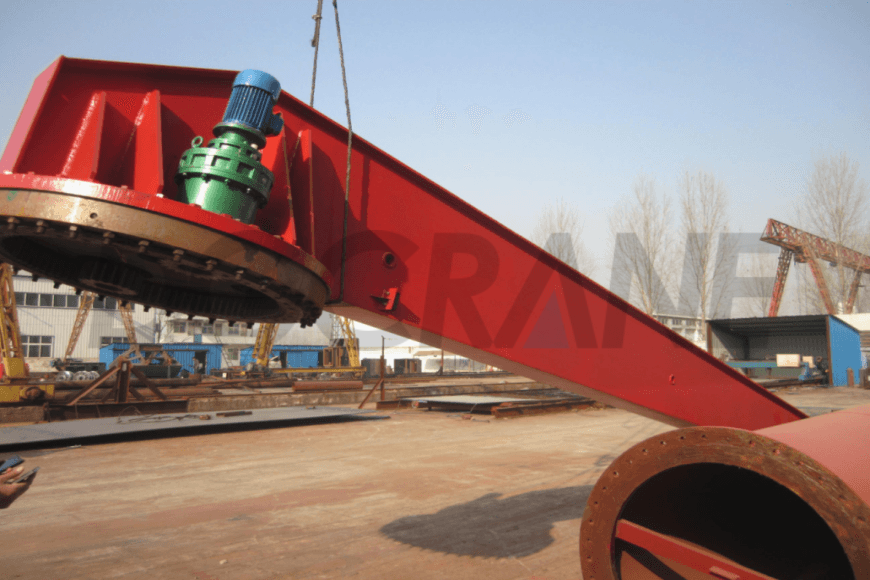

4 Sets of 3.2 Ton Free standing Jib Cranes Delivered to Mexico

This is a well-known company in Mexico, and we have frequently collaborated with them.

This is a European type of jib crane that operates at A5 duty. It features an electric hoist with dual lifting speeds. The hoist traveling and slewing speeds of the jib crane are controlled by an inverter. We use Schneider brand VFD and electrical components. The jib crane arms are very long, but we can design them accordingly.

Specification:

- Model: Free standing Jib crane

- Lifting capacity: 3.2 Ton

- Total Length of Arm: 11m

- Effective arm length: 11 m

- Lifting Height:7m

- Power Source: 440V/60HZ/3PH (24V)

- Lifting mechanism: Electric hoist

- Slewing Angle: 360°

- Hoisting Speed: 5/0.8 m/min

- Hoist crossing speed: 5-20 m/min

- Slewing speed: 0-0.6 r/min

- Temperature: -20°C to+40°C

- Work duty: M5

- Control Method: Pendant line with Push Button + Wireless remote control

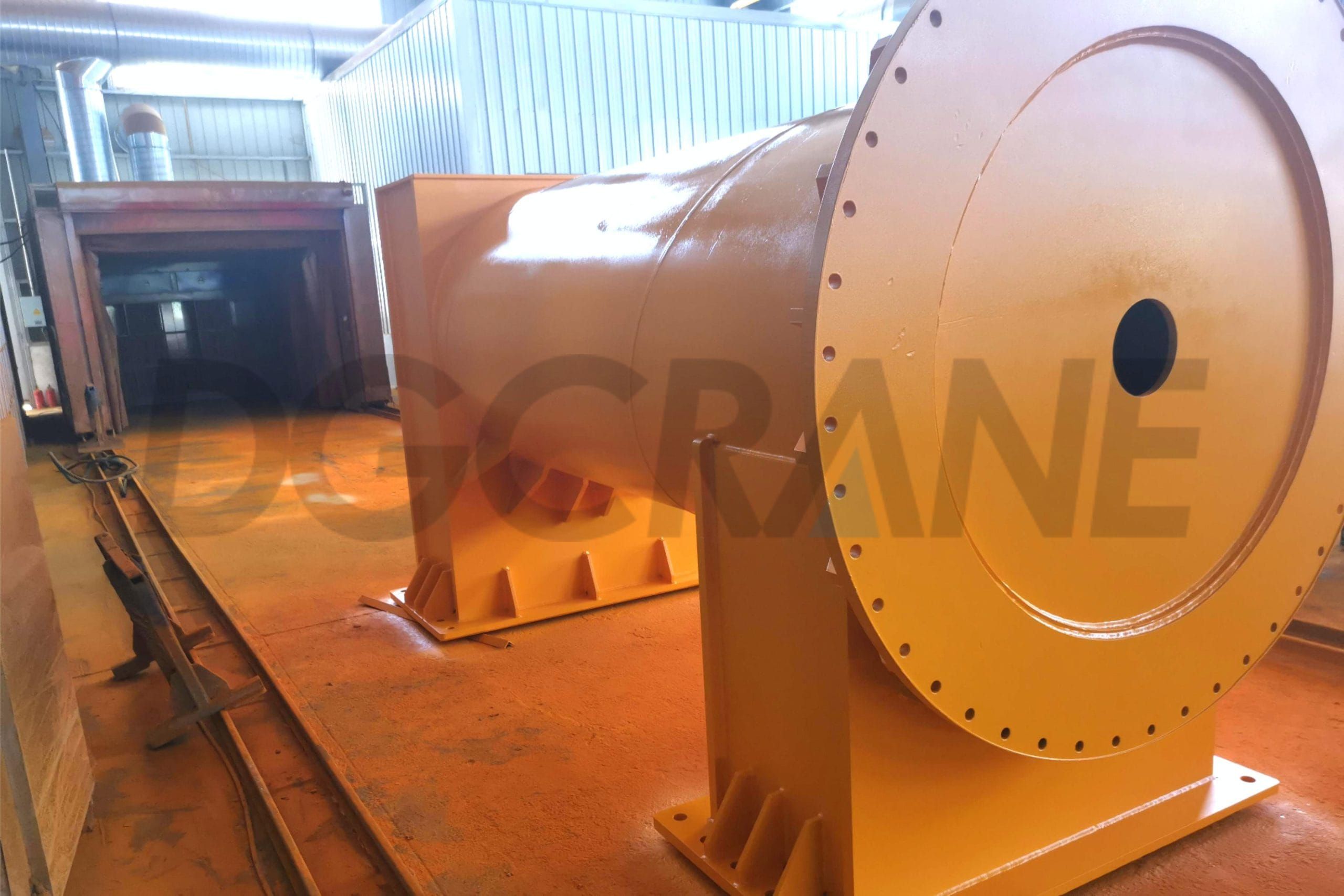

5 Ton Free Standing Jib Crane Exported to Russia

Specification:

- Lift Capacity: 5 ton

- Lift Height: 6m

- Arm Length: 8m

- Control Method: Remote Control

- Power: 380v, 50hz, 3ac

5 Ton Jib Crane – Frequently Asked Questions (FAQ)

What is a 5 ton jib crane used for?

A 5 ton jib crane is commonly used for handling medium to heavy materials in various industrial settings such as manufacturing plants, maintenance workshops, assembly lines, and logistics areas. It is ideal for short-distance, repetitive lifting tasks where flexibility and efficiency are needed.

How much does a 5 ton jib crane cost?

The cost of a 5 ton jib crane depends heavily on its configuration and customization. Factors that influence the price include the type of jib crane, arm length, lifting height, rotation angle, hoist type (electric chain or wire rope), and installation conditions. Because each crane is tailored to the customer's specific requirements, we recommend contacting us directly with your lifting and site details to receive a precise quotation.

Can I install a 5 ton jib crane outdoors?

Yes, a 5 ton jib crane can be installed outdoors, provided it is designed and manufactured with weatherproof materials. We offer outdoor-grade options with corrosion-resistant finishes, IP-rated electrical enclosures, and sealed hoists to withstand harsh environmental conditions such as rain, dust, and extreme temperatures.

Do you offer installation and commissioning services?

Yes, we offer full installation and commissioning services for our jib cranes. Our team can assist with on-site installation, alignment, load testing, and operator training. For international clients, we provide detailed installation guides, remote video support, and on-demand technician dispatch if required.

Are your 5 ton jib cranes compliant with international safety standards?

Absolutely. Our 5 ton jib cranes are designed and manufactured according to recognized international standards such as FEM (Europe), ISO, ANSI/ASME (USA), and other applicable national safety codes. We can also provide certificates of conformity, load test reports, and third-party inspections as needed.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!