30 Ton Gantry Crane for Sale: Durable, Customizable and Cost-Effective

Table of Contents

The 30 Ton Gantry Crane series offers a comprehensive selection of L-type single girder, A-type double girder, and U-type double girder configurations, ensuring optimal solutions for a wide range of heavy lifting tasks. Designed for durability, efficiency, and adaptability, these cranes combine robust structural design with advanced control and safety features.

Whether used in manufacturing plants, construction sites, shipyards, or container terminals, our 30 ton gantry cranes deliver stable performance, long service life, and the flexibility to meet diverse operational requirements.

30 Ton L-frame Single Girder Gantry Crane

Features:

- L-shaped Structure: The legs and the lower crossbeam form an L-shape, providing a large lifting space and strong cross-span capability. This design makes it convenient to transfer loads from within the span to under the cantilever.

- Single Girder Design: Simple structure, easy to manufacture and install, and lighter self-weight. However, its overall rigidity is relatively weaker compared to double girder gantry cranes, making it suitable for applications with smaller lifting capacities and spans.

- Lifting Capacity and Span: The lifting capacity generally ranges from 5 to 50 tons, with spans up to 35 meters. It is ideal for loading and unloading operations in open-air locations such as docks, port yards, and the shipbuilding industry, meeting the handling needs of various large cargoes.

- Working Environment: Mainly used in outdoor areas like cargo yards and docks. Thanks to its structural characteristics, it is suitable for sites with large spans and high lifting heights, often employed for handling large loads such as containers and steel materials, offering strong load-bearing capacity.

30 Ton Double Girder A-frame Gantry Crane

Features:

- Structural Characteristics: The legs of the A-type gantry crane are arranged in an “A” shape, with a relatively simple structure. It typically adopts a double girder design, and the main girders are mostly box-type structures, offering high rigidity and load-bearing capacity.

- Load Capacity: Compared to U-type gantry cranes, the load capacity is relatively lower, generally suitable for operations within the medium to small lifting capacity range.

- Operational Stability: Under the same conditions, the operational stability of an A-type gantry crane is slightly weaker than that of a U-type gantry crane and may exhibit slight vibrations. However, it can still meet normal operational requirements within medium load and span ranges.

- Applications: Suitable for medium-scale industrial environments, such as medium-sized machinery plants, warehouses, and building material markets. It is mainly used for lifting medium-weight goods, such as steel materials, containers, and mechanical components. In space-constrained environments, the A-type gantry crane can better adapt to the site conditions, and its compact structural design allows for good operational flexibility even in narrow passages or limited working areas.

30 Ton U-frame Double Girder Gantry Crane

Features:

- Structural Characteristics: The legs and lower crossbeam form a “U” shape, with vertical legs. This design provides a large clearance between the legs, allowing oversized and heavy loads to pass through while eliminating the need for a saddle frame. As a result, the overall height is lower, and the structure has good manufacturability.

- Load Capacity: With a large trolley gauge, the structure offers excellent stability and strong load-bearing capacity, making it suitable for handling heavy-duty cargo.

- Self-weight and Cost: Compared to an A-type gantry crane with the same lifting capacity, the U-type has a greater self-weight and higher manufacturing cost.

- Applications: Widely used in outdoor yards, railway freight yards, heavy-duty ports, container berths, ship loading and unloading operations, and front yard stacking and transportation in open-air sites.

30 Ton Gantry Crane Price

The 30 Ton Gantry Crane price varies depending on specific configurations such as span, lifting height, girder type, control system, and additional safety features. Different application scenarios may require different designs, which can significantly influence the overall cost. Below, we have listed some sample prices for reference only — the final quotation will be tailored to your exact requirements.

| Products | Span/m | Work Duty | Lifting Height/m | Control Mode | Price/USD |

| 30/10 Ton Single Girder Gantry Crane | 24 | A5 | 12 | Cabin Control | $77,639 |

| 30/10 Ton Single Girder Gantry Crane | 24 | A3 | 12 | Cabin Control | $69,750 |

| 15+15 Ton Single Girder Gantry Crane | 20 | A3 | 10 | Remote Control | $179,861 |

| 32/10 Ton Double Girder Gantry Crane | 35 | A5 | 12 | Remote Control+Cabin Control | $111,144 |

| 32/10 Ton Double Girder Gantry Crane | 32 | A5 | 12 | Remote Control+Cabin Control | $108,554 |

| 32/5 Ton Double Girder Gantry Crane | 39.5 | A5 | 13 | Remote Control+Cabin Control | $120,361 |

| 25/5 Ton Single Girder Gantry Crane | 36 | A3 | 9 | Remote Control | $38,389 |

For an accurate and competitive 30 ton gantry crane price tailored to your needs, please contact our sales team directly. By understanding your lifting capacity requirements, working environment, and preferred configurations, we can provide you with a customized quotation and professional technical advice — ensuring you get the best value and performance for your investment.

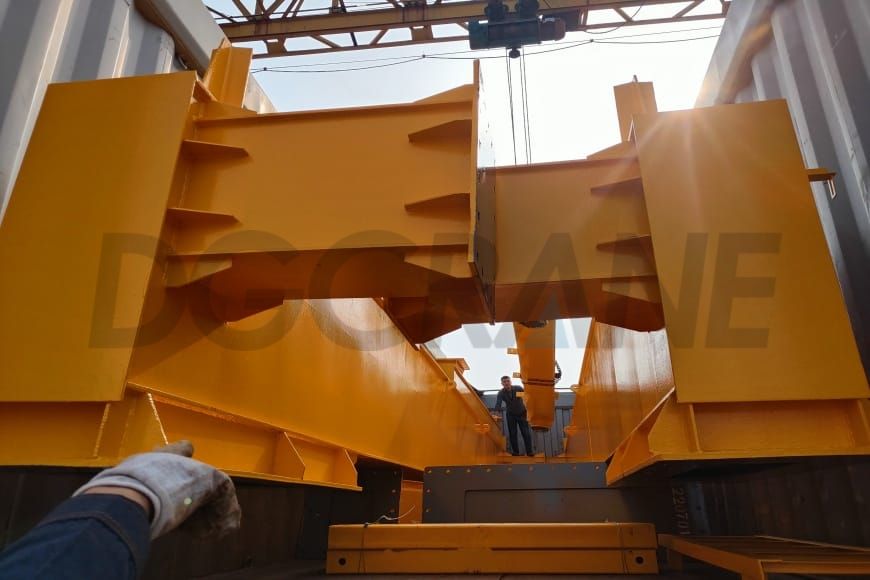

DGCRANE 30 Ton Gantry Crane Cases

Here we present a selection of gantry crane projects in different specifications and configurations, tailored to diverse lifting environments and operational requirements. These cases highlight our expertise in providing tailored solutions that maximize efficiency, reliability, and adaptability across various working conditions.

30/5 Ton Double Girder Gantry Crane Delivered to Thailand

In this project, instead of using the traditional LH hoist trolley, we recommended our European-style MG hoist trolley. This upgrade provides a higher work duty rating and a greater full-load capacity, making it better suited for the customer's intensive lifting requirements.

During operation, the MG hoist trolley runs smoothly with minimal noise, even under high-frequency use. Its longer service life and stable performance have earned strong praise from the client, ensuring efficient and reliable crane operation for years to come.

Specifications:

- Crane Type: Double girder gantry crane

- Country: Thailand

- Capacity: 30/5 ton

- Span: 20 m

- Lifting Height: 8 m

- Work Duty: A5

- Control Mode: Remote control+Cabin control

- Power Supply: 380V/50Hz/3Ph

30 Ton Double Girder Gantry Crane Exported to Argentina

Specifications:

- Capacity: 30 ton

- Span Length: 10.5 m

- Lifting Height: 8 m

- Work Class: A3

- Control Mode: Pendant +Joystick remote control

- Power Source: 380V/50Hz/3Ph

- Installation Site: Argentina

25 Ton Double Girder Gantry Crane Delivered to Qatar

This is a very well-known company in Qatar, and we have worked together many times. The work duty of the European-type double girder gantry crane is A5. The electric hoist features double lifting speeds, while both the hoist traveling and crane traveling speeds are controlled by inverters. We use Schneider brand VFDs and electrical components. This double girder gantry crane was exported to our client at the end of January 2023, and the customer put it into operation in October last year.

Specifications:

- Crane Type: Double girder gantry crane

- Country: Qatar

- Capacity: 25 ton

- Crane Span: 33 m

- Lifting Height: 13 m

- Control Mode: Pendant control with button+Wireless remote control

- Voltage: 415V/50HZ/3PH

- Working Grade: A5

- Protection Grade: Insulation F/ IP55

25/10 Ton Double Girder Gantry Crane For Sale to Chile

This is a new customer from Chile. We spent two months finalizing the order. Back in 2020, we delivered jib cranes and a European double girder overhead crane to Chile, which became an important reference for the customer's decision-making.

This gantry crane is for the customer's own use, and they place great emphasis on product quality. Before placing the order, they arranged for SGS to conduct a factory inspection. During the production process, they also had SGS perform a dimensional check and packaging inspection. We passed all the tests successfully.

Specifications:

- Capacity: 25/10 ton

- Span Length: 19 m

- Lifting Height: 12 m

- Work Duty: A5

- Motor Protection Grade: IP55

- Power Source: 380V/50Hz/3Ph

30 Ton Gantry Crane – FAQ

What is a 30 ton gantry crane used for?

A 30 ton gantry crane is ideal for lifting and moving heavy loads in shipyards, steel fabrication plants, manufacturing workshops, construction sites, and container terminals. Whether you need a 30 ton gantry crane for sale or a customized solution, it can handle bulk materials, steel plates, prefabricated sections, and oversized cargo with ease.

What types of 30 ton gantry cranes are available?

We offer single girder and double girder designs, as well as L-frame, A-frame, and U-frame configurations. Each 30 ton gantry crane is engineered to match your site conditions and lifting needs.

Single girder vs double girder – which is better for 30 tons?

Single girder gantry cranes are lighter and more economical, making them ideal for moderate-duty applications, while double girder gantry cranes offer greater strength, higher lifting heights, and are perfect for heavy-duty and high-frequency operations.

Can the crane be customized?

Absolutely. We can customize span, lifting height, travel speed, control mode, and additional features for your 30 ton gantry crane for sale.

What safety features are included?

Our cranes come with overload limiters, limit switches, buffer stops, emergency stops, anti-collision devices, and windproof systems for outdoor use.

What after-sales services are provided?

We provide spare parts, technical support, on-site service if needed, and regular inspection guidance to keep your 30 ton gantry crane in top condition.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!