2 Ton Jib Crane Selection Guide: Compare Types, Features, and Costs

Table of Contents

When purchasing a 2 ton jib crane, maximizing space utilization, controlling costs, and ensuring operational safety are key concerns for every equipment manager. Different working environments demand different installation methods, rotation ranges, load-bearing structures, and even explosion-proof standards.

To help you better understand the practical applications and configuration strategies for 2 ton jib cranes, this article compares three mainstream types—free-standing, wall-mounted, and wall-traveling jib cranes. We'll explore their technical specifications, application scenarios, and cost considerations to provide a comprehensive overview. Whether you’re planning a new facility or upgrading an existing one, we are committed to delivering stable, reliable, and customized lifting solutions that support safe and efficient operations.

2 Ton Jib Crane Types

Free Standing Jib Crane

A free standing jib crane is installed by anchoring a vertical column to a concrete foundation, typically using foundation bolts. The jib arm rotates around the pillar, while an electric hoist travels along the arm to enable vertical lifting and horizontal movement of materials.

Features:

- Mounted on the floor with an independent foundation

- Rotation angle typically 180°, 270°, or 360°

- Small footprint, ideal for fixed workstations

- Lifting coverage forms a sector-shaped area under the jib arm

Application

Wall Travelling Jib Crane

A wall travelling jib crane is equipped with a horizontal track mounted on a wall or column, allowing the jib arm to travel horizontally along the track. At the same time, the electric hoist moves along the jib arm, significantly expanding the working range.

Features:

- No floor foundation required, saving even more space

- Commonly mounted on structural walls or columns

- Limited rotation angle (typically ≤180°)

- Ideal for wall-side work areas or setups with multiple workstations

Application

Wall Travelling Jib Crane

A wall travelling jib crane is equipped with a horizontal track mounted on a wall or column, allowing the jib arm to travel horizontally along the track. At the same time, the electric hoist moves along the jib arm, significantly expanding the working range.

Features:

- Wider lifting coverage, capable of spanning long horizontal distances

- The lifting mechanism travels along the wall-mounted track to serve multiple workstations

- Ideal for material handling along production lines inside factories

- Requires high wall strength and precise installation conditions

Application

2 Ton Jib Crane Type Comparison Table

| Comparison Dimension | Free Standing Jib Crane | Wall Mounted Jib Crane | Wall Travelling Jib Crane |

| Installation Method | Free-standing column mounted on floor | Directly fixed to load-bearing wall | Track mounted along wall; jib arm travels |

| Rotation Angle | 180° or 360° (flexible) | Fixed angle (typically ≤180°) | No rotation |

| Mobility | Fixed position, non-movable | Fixed position, non-movable | Jib arm travels horizontally along track |

| Typical Applications | Independent workstations, multi-directional lifting | Wall-side operations, compact spaces | Long walls, multi-station, flexible scheduling |

| Space Usage | Occupies floor space | Minimal floor space | Requires only wall-mounted track space |

| Installation Complexity | Medium (requires reinforced foundation) | Simple (wall must meet load requirements) | High (track installation + alignment) |

Quick Selection Guide

- Choose Free-standing Jib Crane: For 360° rotation, independent workstations, and high-frequency operations.

- Choose Wall-Mounted Jib Crane: For narrow spaces, limited budgets, and fixed wall-side lifting.

- Choose Wall-Travelling Jib Crane: For long wall areas with multiple workstations requiring horizontal movement and jib coordination.

2 Ton Jib Crane Price

Free-standing, wall-mounted, and wall-traveling jib cranes all feature a high degree of customization to meet the unique needs of different workspaces and applications. Factors such as installation environment, load capacity, rotation angle, jib length, and mounting structure can all be tailored based on your specific requirements.

To receive an accurate quotation and personalized solution, please contact us directly. Our engineering team will provide one-on-one support to help you select the most suitable model and configuration.

2 Ton Jib Crane Cases

8 Sets of 2 Ton Wall Mounted Jib Cranes Delivered to Peru

Project Background & Client Overview

- The client is based in Lima, Peru, and operates a factory focused on pipeline processing.

- We have maintained a strong partnership for two years, and this marks their fourth order.

- Previous purchases include: 15 sets of 2 ton column-mounted jib cranes, 2 sets of 3 ton semi-gantry cranes, and 1 set of a 5 ton single girder gantry crane.

Current Order & Application

- This order includes 8 sets of 2 ton wall mounted jib cranes.

- Application: For use in a newly built workshop as part of the client's facility expansion.

- Initially, the client intended to order free standing cranes again, but after evaluating the workshop layout, our engineers recommended wall mounted jib cranes to reduce both cost and installation time.

Technical Design & Customization

- The wall mounted cranes required custom bearing brackets to fit the specific H-beam dimensions.

- We confirmed all structural details after receiving the plant layout and site photos from the client.

- The wall mounted solution greatly improves space efficiency, especially for operations near walls or tight zones.

Technical Advantages & Delivery

- The cranes were designed under the guidance of Mr. Zhang, one of the engineers who helped draft the National Standard for Cantilever Cranes.

- The rotation mechanism was upgraded through collaboration with a German partner, ensuring smoother and more stable operation.

- All 8 cranes have been successfully installed and commissioned at the client’s facility in Lima.

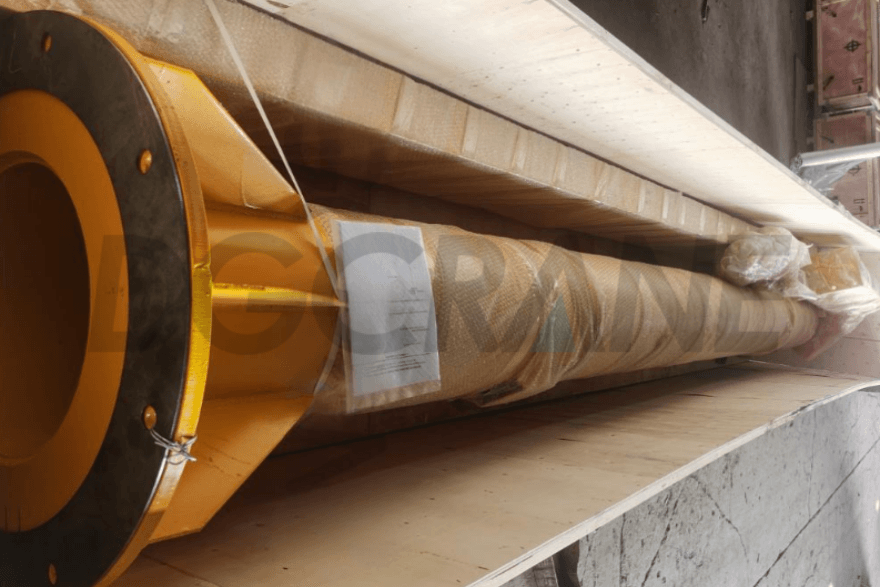

BZD 2 Ton Explosion-proof Column Mounted Jib Crane Exported to Kuwait

Our valued customer in Kuwait placed an urgent order for a 2-ton explosion-proof column-mounted jib crane. To meet their timeline, we expedited production and completed the crane according to the client's specific requirements.

As the crane was to be shipped by air, we ensured safe transport by packing it in a high-strength plywood crate.

Specification:

- BZD 2 ton column mounted jib crane

- Country: Kuwait

- Capacity: 2 ton

- Working radius: 5m

- Lifting height: 4m

- Lifting speed: 8m/min

- Hoist traversing speed: 20m/min

- Slewing speed: 0.6r/min

- Slewing angle: 360°

- Explosion-proof grade: DIP A21 TA,T4 (powder explosion-proof)

- Control method: Pendant control

- Power supply: 600V 60Hz 3Ph

Customized 2 Ton Jib Crane Solution for Client in Turkey

This customer maintains a very busy daily schedule and has limited availability to discuss the jib crane project in detail. As a result, our communication was interrupted multiple times throughout the negotiation process. Despite these challenges, we remained patient and responsive, providing timely technical support and proposals whenever the opportunity arose.

Over the course of nearly a year, we worked closely with the client to clarify key details such as crane specifications, working environment conditions, and operating radius. Through this persistent effort and mutual understanding, we were pleased to finally receive a trial order, marking an important first step in our cooperation.

Specification:

- Model: free stranding jib crane

- lifting capacity: 2 ton

- lifting height: 5 m

- span length: 6 m

- application: stone processing factory (indoor)

- quantity: 5 sets

Conclusion

Through the comparative analysis and case examples in this guide, we hope you now have a clearer understanding of the application scenarios and selection logic for free stranding, wall mounted, and wall travelling jib cranes.

Although 2 ton jib cranes are classified as light-duty equipment, factors such as space compatibility, safety compliance, and cost control still require careful evaluation.

We trust this guide will help you navigate complex specifications and make accurate decisions to achieve your procurement goals—functionally matched, space-efficient, and safety-compliant.

If you require further technical support or would like a customized quotation, feel free to contact us anytime.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!