10 Ton Gantry Crane for Sale: High-Quality, Cost-Effective and Globally Proven

Table of Contents

Looking for a dependable 10 ton gantry crane for sale that meets the highest standards of safety, efficiency, and performance? At DGCRANE, we specialize in supplying a wide range of 10 ton gantry cranes to customers across more than 120 countries. With years of export experience and a deep understanding of global market demands, we provide tailored crane solutions that fit diverse industrial needs.

In this guide, you'll find a comprehensive overview of 10 ton gantry crane types, key pricing insights, and real-world export cases that showcase DGCRANE’s global project experience. If you’re in the market for a 10 ton gantry crane, you’ve come to the right place.

Simple structure, wide range of applications, and high cost performance

A commonly used double-girder gantry crane structure in the market

U-shaped gantry design with large leg clearance, ideal for bulky item handling

Modular and silent design, intelligent control, environmentally friendly

Modular and silent design, intelligent control, energy-saving and low consumption

Can be mounted on existing workshop supports, maximizing space under the main beam

Highly customizable for different operations (e.g., adjustable height/span, portable)

Truss structure: lightweight, low wheel load, strong wind resistance

10 Ton Gantry Crane Price

The price of a 10 ton gantry crane depends on multiple factors, such as crane type, span, lifting height, material handling requirements, and custom features. At DGCRANE, we are committed to offering high-quality gantry cranes at competitive prices. Our products are built with durable components, efficient designs, and strong safety standards—making them a reliable and affordable choice for industries worldwide.

| Products | Span/m | Lifting Height/m | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 10 Ton Single Girder Gantry Crane | 14-30 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 10 Ton Double Girder Gantry Crane(A Type) | 18-35 | 10/12m or customized | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 10 Ton Double Girder Gantry Crane(U Type) | 18-35 | 10/12m or customized | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 10 Ton FEM Single Girder Gantry Crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 10 Ton FEM Double Girder Gantry Crane | 7.5-28.5 | 6/9/12m or customized | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 10 Ton Semi Gantry Cranes | 10-20 | 6 | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 10 Ton Truss Gantry Crane | 14-30 | 6/9/12m or customized | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

Note: Prices may change based on market conditions. Please contact our sales team for the latest quote.

The 10 ton portable gantry crane is a highly customizable solution designed for flexible lifting needs without the need for track installation. Due to the wide range of design options—such as adjustable height, span, wheels, and mobility features—we do not list a fixed price for this model.

For accurate specifications and pricing, please contact our engineers. We will help you design the right solution based on your specific application and working environment.

Get a free consultation today and let us help you build the right crane for your project.

10 Ton Gantry Crane Cases

DGCRANE has exported gantry cranes to over 120 countries, serving a wide range of industries with reliable and cost-effective lifting solutions. With hundreds of successful projects worldwide, our experience ensures high-quality performance across different working environments.

Here we briefly introduce 5 representative 10 ton gantry crane cases to showcase the versatility and global reach of our products.

10 Ton Gantry Crane Sold to Hong Kong

After 7 days of dedicated work, the 10 ton gantry crane was successfully installed and commissioned in Hong Kong. Mr. Stephen was highly satisfied with our professional service and efficient execution.

Project Overview

- Type: 10 Ton Single Girder Gantry Crane

- Capacity: 10 Ton

- Span: 11.8 m

- Lifting Height: 5 m

- Quantity: 1 Set

- Shipment: 40 Feet Open Top Container

Project Background & Solution

In October 2013, Mr. Stephen inquired about a 10-ton single girder overhead crane. To ensure our solution was the most suitable, we requested layout plans and photos for further evaluation.

Upon review, we found that the facility was not designed for an overhead crane, with no supports in place. After discussions with Mr. Stephen, our engineers recommended a gantry crane solution, which was more economical and practical given the site's limitations.

Additionally, our engineers proposed using square steel and subplate as rail foundations, and optimized the crane's travel system by incorporating wheel blocks to distribute the load for added safety.

Design Optimization & Efficient Delivery

To fit the crane into a 40-foot container, we modified the connection between the main girder and bearing beams to a detachable design, improving shipping efficiency.

We provided Mr. Stephen with pre-assembly instructions and drawings. Meanwhile, we arranged for engineers to travel to Hong Kong for assembly and commissioning.

10 Ton Single Girder Gantry Crane Sold to Peru

We've been supplying overhead cranes, gantry cranes, and jib cranes to Peru since 2012. This particular customer was introduced by one of our long-term partners in Peru. After visiting our facilities and inspecting our products, they were satisfied with the quality, which helped us close the deal quickly—approximately one month from inquiry to order confirmation.

Project Overview

- Capacity: 10 ton

- Span length: 18.5m

- Lifting height: 4.6m

- Work Duty: A5

- Power source: 380V/60Hz/3Ph

- Indoor Use

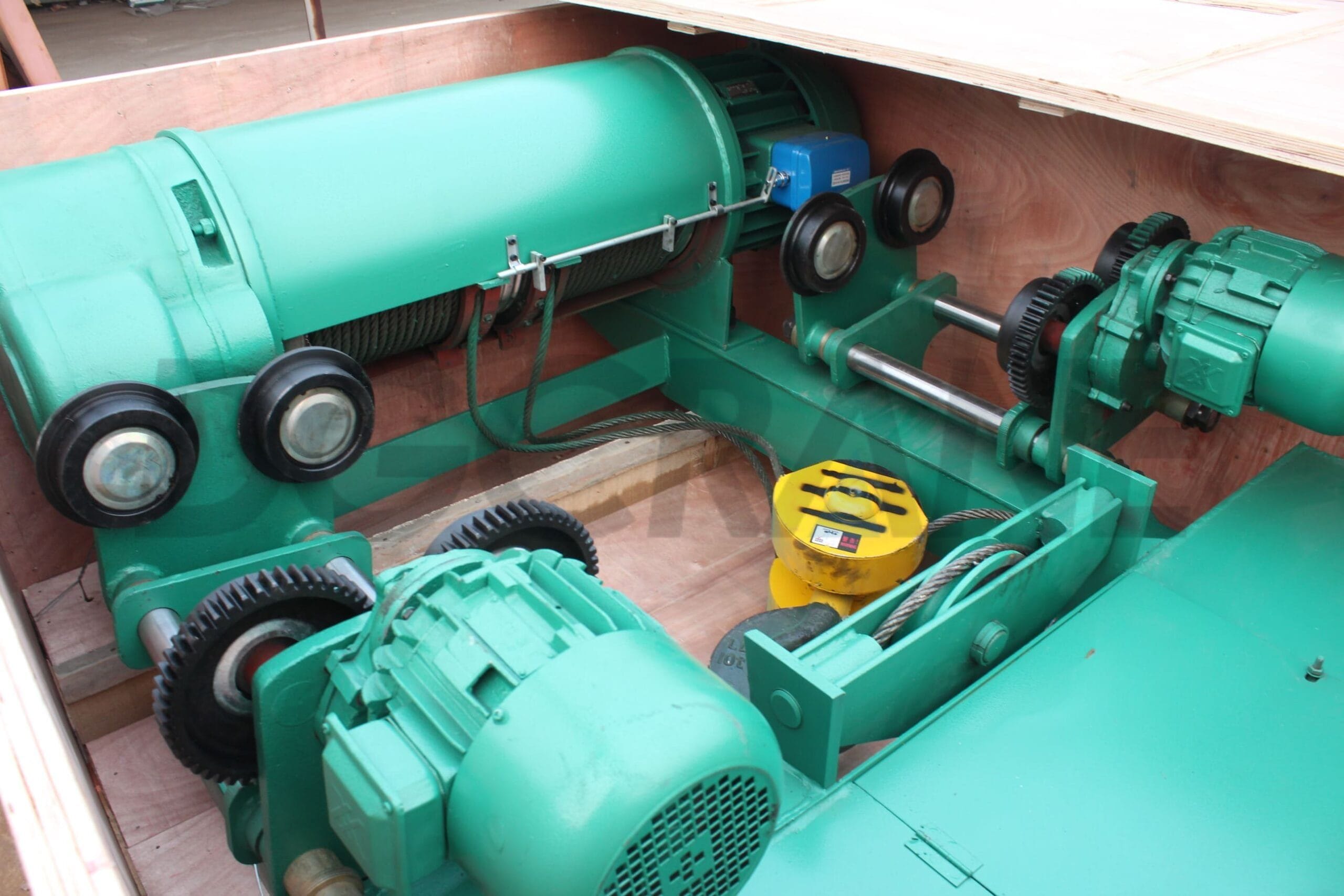

The cranes are intended for use inside the workshop, where there are no runway beams or support columns. Based on this, we recommended a gantry crane solution. Considering the workshop's clearance height of 6.8 meters, we chose a low headroom hoist and a box girder crane design, which allows for maximum lifting height.

The cranes feature dual-speed lifting and soft-start motors for both the cross travel and crane travel functions, minimizing noise and mechanical impact. This design provided the most economical solution for the customer’s indoor use.

2 Sets of 10 Ton Gantry Cranes Sold to Kenya

Project Background & Process

The customer, a long-time player in the oil tank manufacturing industry, initially preferred Siemens motors for the cranes. After several rounds of email discussions, we provided a quotation and a proforma invoice. Despite some delays in communication, the customer eventually reached out, confirming their visit to China.

During their visit, I invited them to our factory, but they expressed trust in our company and were confident in our product quality and service. Shortly after returning to Kenya, the customer placed the order.

After around three months of discussions, we successfully confirmed the order for 2 sets of 10 ton, 6m span single girder gantry cranes.

Project Overview

- Customer: Specialized in oil tank manufacturing

- Order Confirmation Date: May 16, 2013

- Delivery Port: Qingdao Port

Technical Specifications

- Lifting Capacity: 10 Ton

- Lifting Height: 7 M

- Span Length: 6 M

- Crane Traveling Length: 43 M

- Special Request: Siemens Brand Motor

- Quantity: 2 Sets

3 Sets of Semi Double Girder Gantry Cranes Sold to the Philippines

These 3 sets of 10 ton semi-gantry cranes were delivered to our client in July 2020. The cranes are used for handling steel bars, billets, and other heavy materials.

Due to the high working frequency required in their operations, we selected an A5 duty group design to ensure long-term durability and reliable performance under demanding conditions.

Project Overview

- Type: Semi Double Girder Gantry Crane

- Quantity: 3 Sets

- Lifting Capacity: 10 ton

- Span: 22m

- Lifting Height: 9.5m

- Lifting Mechanism: 10t (16t) LH Electric Hoist with Trolley

- Lifting Speed: 3.5m/min

- Trolley Traversing Speed: 20m/min

- Crane Traveling Speed: 3–30m/min

- Control Mode: Cabin Control + Control Handle

- Voltage: 220V, 60Hz, 3-Phase

- Work Site: Outdoor

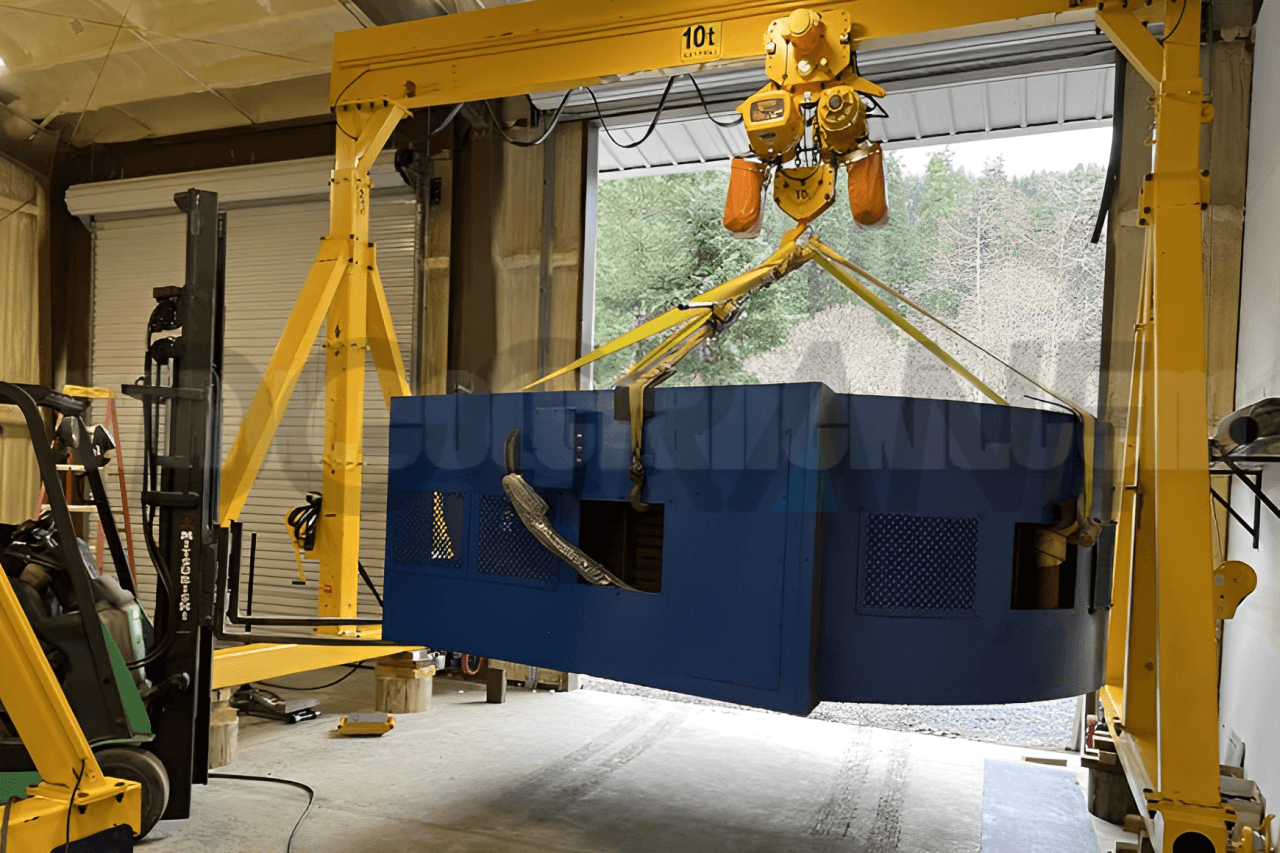

5+5 Ton Gantry Crane Delivered to Saudi Arabia

Project Background

The customer initially inquired about a gantry crane in January 2020. The crane is intended for lifting concrete sleepers, as an addition to an existing gantry crane already on site. We provided a tailored solution and quotation promptly.

Communication with the client was smooth, but due to the impact of COVID-19, the project was temporarily postponed. The contract was eventually signed in September 2020.

In 2021, a sharp increase in sea freight costs led to further delays. After negotiation, we agreed to share part of the shipping cost to support the customer. The crane was successfully shipped to Dammam, Saudi Arabia.

Project Specifications

- Lifting Capacity: 5+5 Ton

- Span Lengths: 30m + 7m + 9m

- Lifting Height: 12m

- Duty Class: A5

- Control Mode: Moving Cabin Room Control

- Power Supply: 380V / 50Hz / 3 Phase

- Main Electrical Components: Schneider

- Frequency Inverter: Schneider

- Installation Site: Saudi Arabia

- Production Lead Time: Approximately 5 Months

10 Ton Gantry Crane Conclusion

Choosing the right gantry crane is about more than just capacity—it’s about reliability, long-term performance, and expert support. At DGCRANE, we’ve helped clients across 120+ countries find tailored lifting solutions, from the widely used 10 ton gantry crane to even larger customized options.

No matter the complexity of your project, our team is here to provide professional guidance and cost-effective options that match your exact needs.

Let's build your ideal gantry crane together — contact us to get started.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!