Overhead Cranes for Concrete Pile Precast Workshop: Versatile Solutions for Demanding Operations

Overhead Cranes for Concrete Pile Precast Workshops are widely used for lifting various raw materials, semi-finished products, and finished products to ensure efficient transportation and stacking, thereby keeping the production line running smoothly. In addition, cranes are also responsible for the installation and maintenance of equipment, providing strong support for safe production in pipe pile plants.

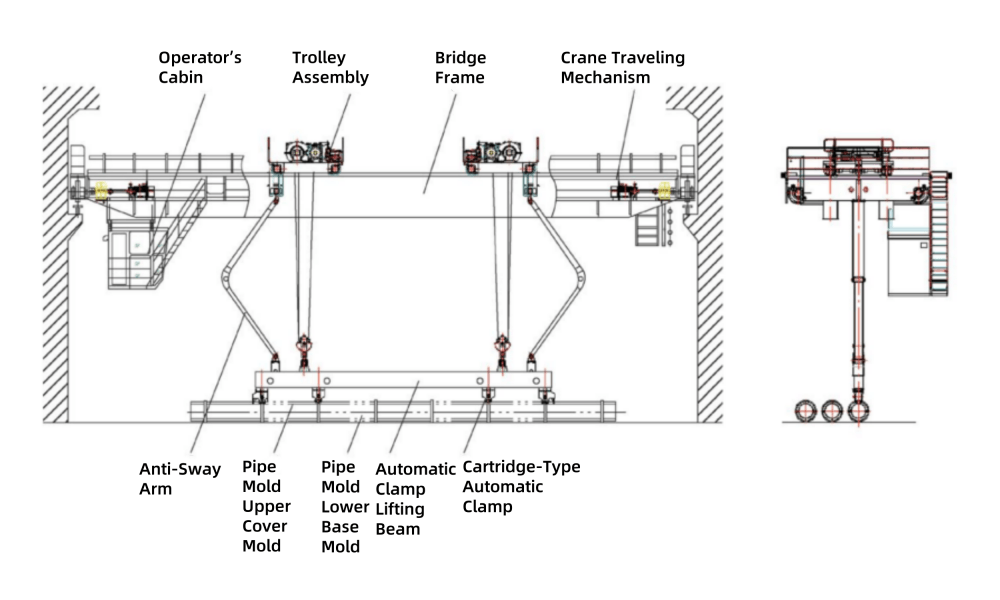

In pipe pile precast workshops, double-girder, double-trolley overhead cranes are generally used, equipped with different lifting attachments according to the requirements of each production stage.

- Crane Type: Double Trolley Overhead Crane

- Duty Class: A7 ~ A8

- Operation Mode: Indoor operation

- Lifting Capacity: 8t + 8t, 10t + 10t, 16t + 16t, and 20t + 20t

- Hoisting Speed: 13 ~ 15 m/min

- Trolley Speed: 30 ~ 45 m/min

- Crane Traveling Speed: 110 ~ 120 m/min

Concrete Pipe Pile Overhead Crane Component

Overhead Crane Spreader for Concrete Pile Precast Workshop

Concrete Pipe pile overhead cranes are equipped with a variety of lifting spreaders tailored to different application scenarios, ensuring efficient and safe handling of all types of lifting tasks. Whether it's transporting heavy pipe piles on a construction site or performing precise operations, we offer customers a wide range of lifting attachment options.

Each attachment is carefully designed to integrate seamlessly with the crane, enhancing operational efficiency and ensuring safety. Below are our recommended lifting attachments for various scenarios, along with their application examples.

Rebar Cage Handling Spreader for Concrete Pile Precast Workshop

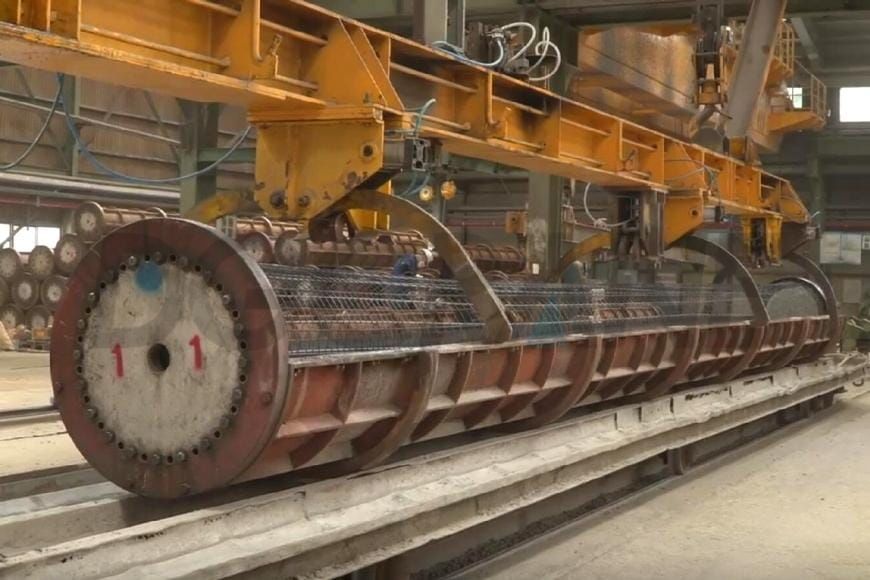

In the rebar cage fabrication workshop, a double-girder, double-trolley overhead crane is equipped with a multi-hook lifting beam attachment. It is used to handle rebar cages that have been welded and formed in the roll-welding section, placing them into the lower mold groove of the pipe mold after end plates have been installed on both ends of the cage body.

The spreader is connected to the crane via a detachable mechanism, allowing for flexible operation with dual modes—either as a standard hook or with the lifting spreader. The lifting beam uses multiple laminated hooks and is fitted with an electric hooking device, making the hooking process simpler and more efficient. With multiple hooking points to support the load, the spreader effectively reduces deformation of the rebar cage caused by its own weight during handling, thereby helping to maintain the quality of the finished product.

Mold Handling Spreader for Concrete Pile Precast Workshop

In the pipe mold assembly workshop, multiple double-girder, double-trolley overhead cranes are installed to handle the opening, closing, and transfer of upper and lower pipe molds. These cranes are equipped with multi-clamp lifting beam attachments, featuring two types of clamps: the caliper-type and the gripper-type. The caliper-type clamp can grip the wheels of the upper pipe mold to facilitate the separation and closing of the upper and lower molds.

Once the rebar cage is placed into the lower mold and securely fixed, the gripper-type clamp on the lifting beam can be used to transport the lower mold together with the cage to the feeding area for concrete pouring. The attachment is equipped with a pneumatic system that enables precise automatic clamping and releasing of the pipe molds during operation, reducing manual effort, minimizing safety risks associated with manual hook alignment, and making the production process safer, more convenient, and more efficient.

Handling of Pipe Molds in High-Temperature Curing and Centrifugal Workshops

In the centrifugal and high-temperature curing workshops, multiple double-girder, double-trolley overhead cranes are installed (the number of cranes is determined according to the actual production requirements of each workshop).

These cranes are primarily used to transport heavy pipe molds onto the centrifuge for forming after the filling and grouting process, and to move the molds into the high-temperature curing chamber for curing after the centrifuging process. The cranes are equipped with caliper-type lifting beam attachments.

To ensure uniform and reasonable load distribution between the attachment and the pipe mold during lifting, the calipers are designed with multiple evenly distributed contact points and are equipped with an overload warning system and real-time load display, fully guaranteeing lifting safety.

To maintain stability during transport and prevent swinging caused by speed changes during crane braking and acceleration/deceleration, foldable anti-sway support arms are installed at both ends of the attachment. This design helps reduce additional swinging loads caused by the crane's inertia, making lifting operations safer and more efficient.

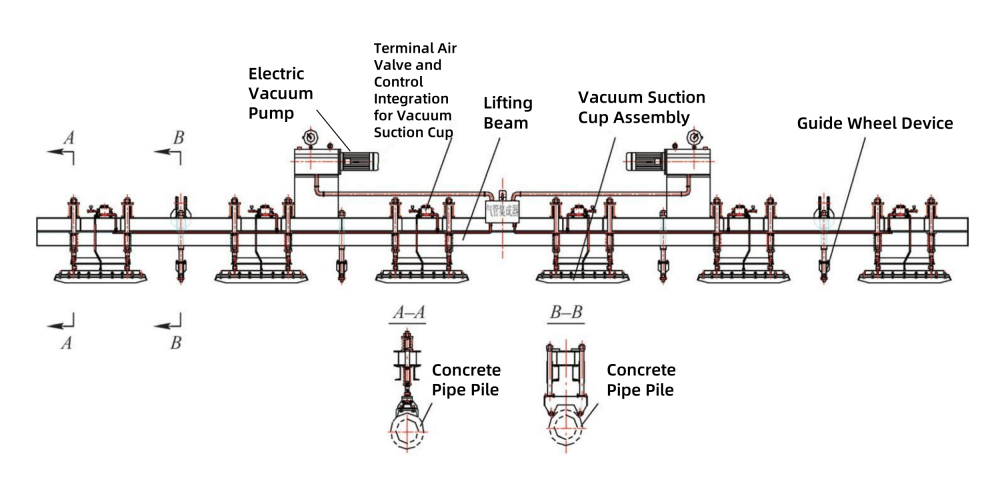

Vacuum Suction Demolding Lifting Spreader for Concrete Pile Precast Workshop

Finished Concrete Pipe Pile Lifting Spreader

Lifting and Transport of a Single Concrete Pipe Pile

Lifting and Transport of Two Concrete Pipe Piles

Lifting and Transport of Three Concrete Pipe Piles

With our expertly engineered lifting solutions for every stage of concrete pipe pile production—from mold handling to finished product transport—you'll achieve higher efficiency, greater safety, and lower operational costs. Choosing our equipment means choosing a reliable partner committed to maximizing your productivity and ensuring every lift is precise, stable, and worry-free.