Galvanizing & Pickling Electric Hoist for Harsh Environments

In the hot-dip galvanizing industry, pickling tanks and zinc kettles are typically enclosed for environmental and safety compliance, leaving only narrow overhead slots that render standard hoists incompatible. Furthermore, these environments subject equipment to extreme temperatures, abrasive zinc dust, and severe chemical corrosion, demanding a specialized lifting solution that standard models cannot provide.

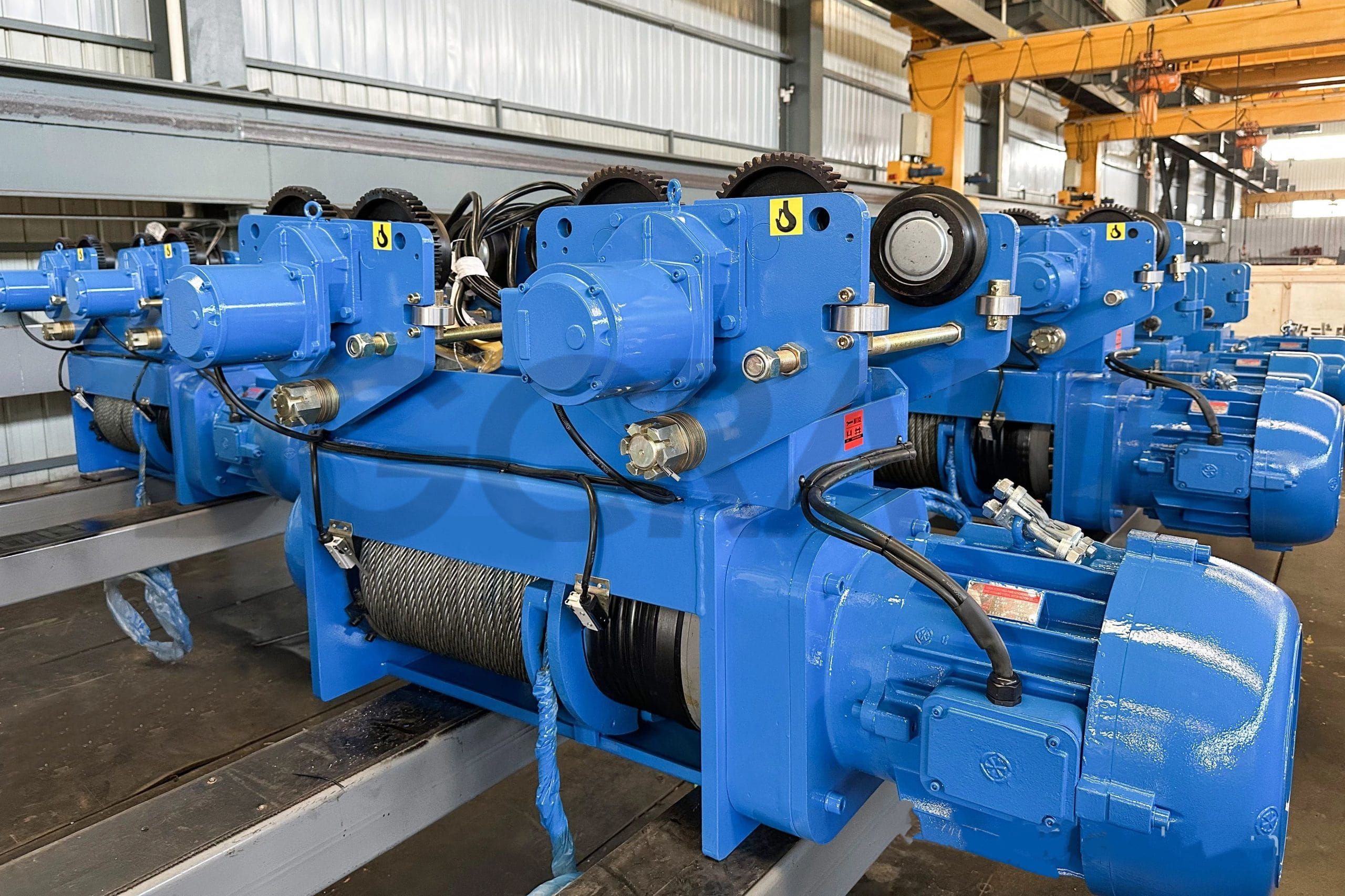

To address these specific challenges, DGCRANE has engineered the FOH Galvanizing & Pickling Electric Hoist, purpose-built for hot-dip galvanizing lines.

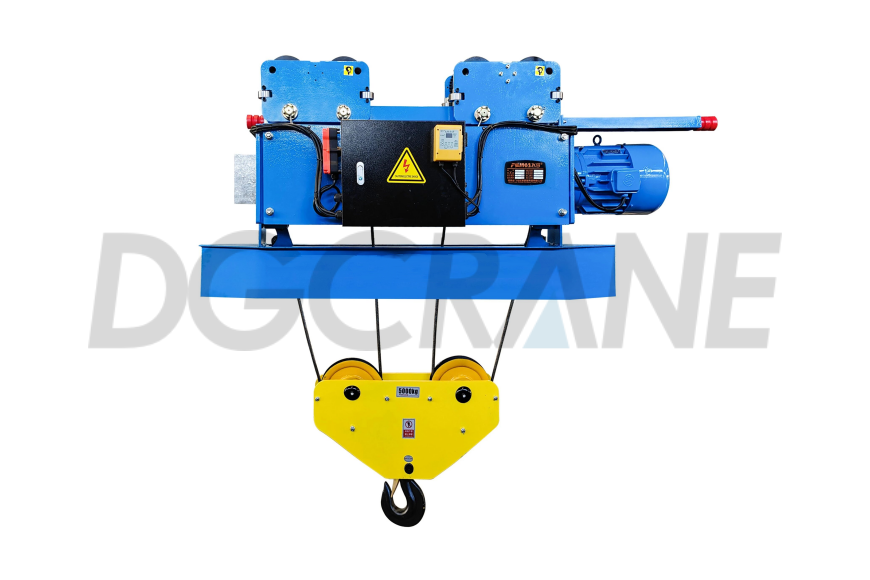

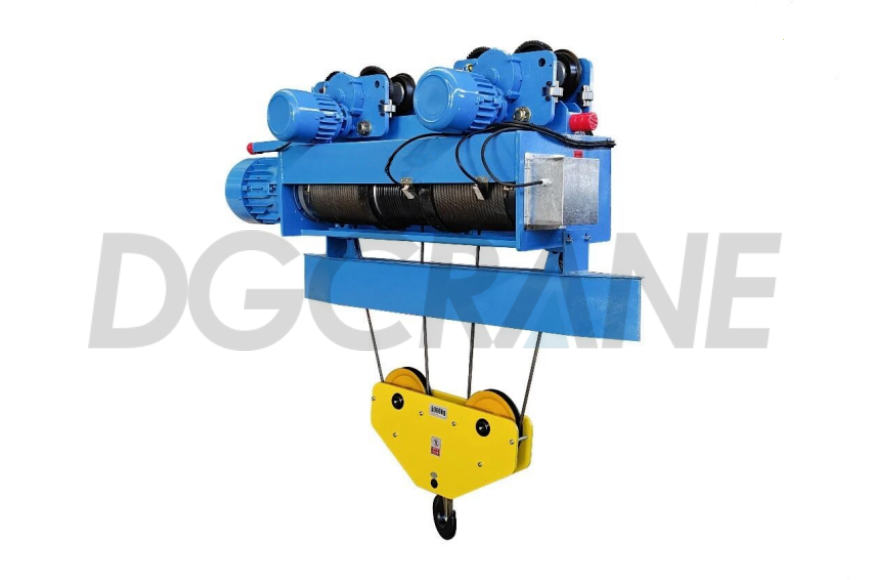

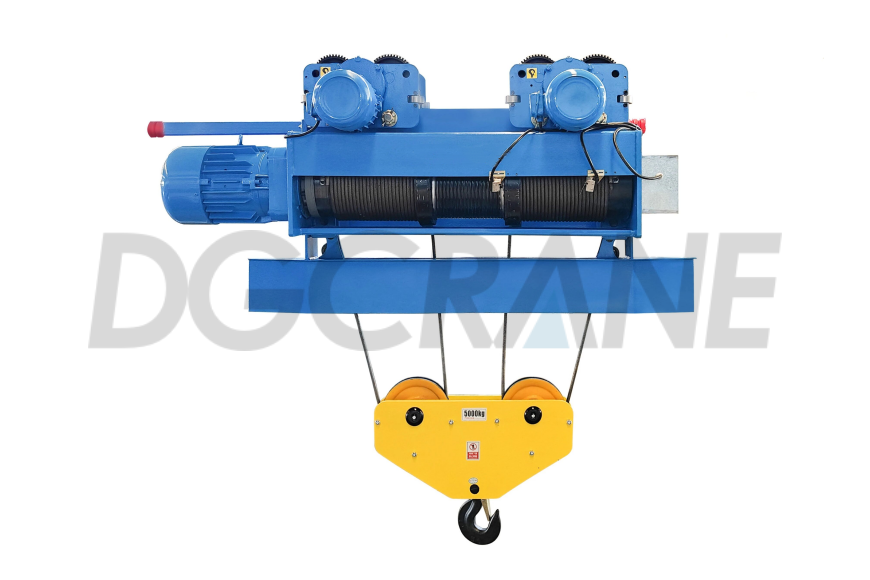

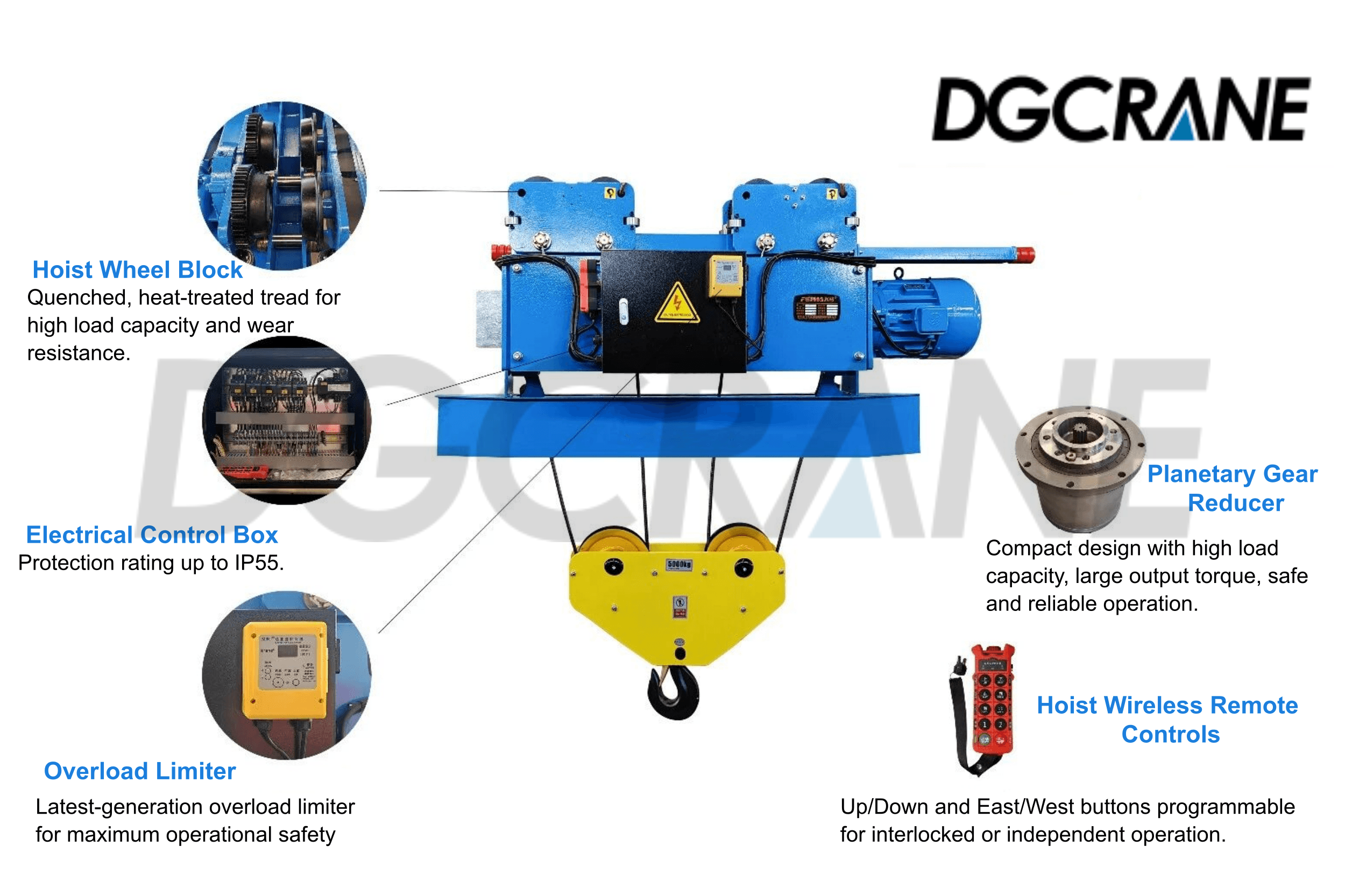

FOH Galvanizing & Pickling Electric Hoist Main Components

Technical Specifications

| Lifting Capacity (t) | 2 | 3 | 5 | 10 | 16 |

| Lifting Height (m) | 6–30 | 6–30 | 6–30 | 6–30 | 9–24 |

| Reeving | 1/2, 2/4 | 1/2, 2/4 | 1/2, 2/4 | 1/2, 2/4 | 1/2, 2/4 |

| Lifting Speed (m/min) | 8, 8/3.3 | 8, 8/3.3 | 8, 8/2.6 | 7, 7/2.6 | 4, 4/1 |

| Lifting Power (kW) | 3.0 | 4.5 | 7.5 | 13 | 13 |

| Travel Speed (m/min) | 20 | 20 | 20 | 20 | 20 |

| Travel Power (kW) | 0.4 | 0.4 | 0.75 | 0.75*2 | 0.75*2 |

| Control Mode | Remote Control / Fully Automated | ||||

| Duty Group | ISO M5 | ||||

| Power Supply | 3-Phase 380V 50Hz | ||||

Key Advantages

- High Performance: Duty class up to ISO M6, featuring high lifting and travel speeds for high-frequency, heavy-load demands.

- Industrial Protection: IP55 rating for motors and electrical cabinets; equipped with high-strength galvanized wire rope.

- Anti-Corrosion Suite: Structural components finished with anti-corrosion paint; all fasteners and connectors are stainless steel or chrome-plated to prevent chemical degradation.

- Stable Drive System: Utilizes a planetary gear reducer for high torque, low noise, and safety-reliable performance.

Other Galvanizing & Pickling Electric Hoists

OHFM European Type Galvanizing & Pickling Electric Hoist

- Capacity: 3 – 16t

- Lifting Height: 6 – 18m

- Travel Speed: 3 – 30m/min

- Lifting Speed: 5 – 12m/min (VFD / Variable Frequency Control)

Engineered for unmanned remote control and high-frequency, precision lifting, meeting the highest international standards for automated production lines.

CDG Galvanizing & Pickling Electric Hoist

Proven technology with superior cost-effectiveness.

- Capacity: 2 – 16t

- Duty Class: ISO M3 / M4

- Lifting Height: 6 – 18m

- Travel Speed: 20 – 30m/min

Supports 4-rope/1-line or 2-rope/1-line reeving; compatible with both straight and curved (loop) track systems.

Galvanizing & Pickling Electric Hoist Cases

OHFM European Type Galvanizing & Pickling Electric Hoist Sold to Dezhou

This bespoke automation solution was engineered for a high-frequency pickling and galvanizing line in Dezhou, achieving full unmanned remote operation with rapid, high-precision handling. Rated ISO M7 for heavy-duty cycles with Class F insulation.

Key Features:

- Smart Control: PLC-integrated interface featuring “one-touch start” automation.

- Connectivity: Real-time data exchange via industrial wireless Access Points (AP) and remote consoles.

- Precision Positioning: Absolute encoders on all axes paired with Barcode Positioning for millimeter-level accuracy.

- Integrated Safety: Multi-tier protection including weight sensors, overload limiters, and anti-collision systems.

FOH Galvanizing & Pickling Electric Hoist with Dual Magnetic Braking Exported to Germany

This project features the FOH Series Electric Wire Rope Hoist, custom-engineered with a planetary drive and a redundant braking system to ensure maximum safety and durability in harsh environments.

Key Features:

- Dual Braking System: Features a primary conical brake and a secondary electromagnetic brake. This redundancy virtually eliminates the risk of brake failure and significantly enhances operational safety.

- Planetary Gear Reducer: Equipped with a high-efficiency planetary gearbox, offering a compact footprint, superior load-bearing capacity, and an extended service life.

- Compact Design: Ideal for narrow overhead slots and restricted-clearance facilities.

DGCRANE delivers reliable, high-performance lifting solutions that balance premium quality with competitive pricing. Supported by a dedicated team of professional engineers, we provide the technical expertise needed to optimize your most challenging galvanizing operations. Contact us today for a consultation and a tailored quote.