Freestanding Workstation Bridge Crane: Lightweight, Modular and Adaptable Material Handling Solution

The freestanding workstation bridge crane operates independently of building columns or runway beams and can be installed directly on the workshop floor. It requires only a simple foundation (C30 concrete, thickness >150 mm), reducing structural costs for new facilities. It can also be flexibly added, dismantled, or relocated in existing workshops to adapt to changing production layouts. Its modular design and enclosed track structure prevent dust accumulation, ensuring smooth, low-resistance movement. The smooth rail surface and optimized trolley design result in low noise, energy efficiency, and environmental friendliness.

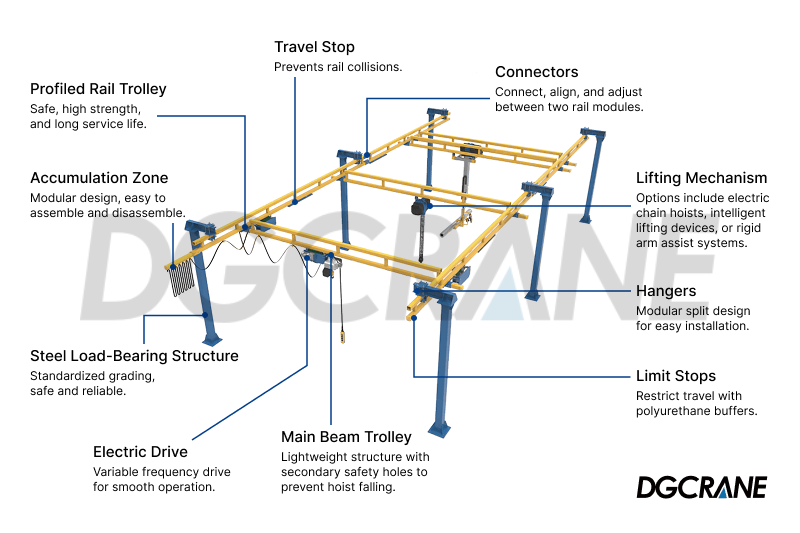

Freestanding Workstation Bridge Crane Components

Single Girder Freestanding Workstation Bridge Crane

The single girder freestanding workstation bridge crane is composed of a truss-style steel runway and other standardized auxiliary components. The truss design allows for greater load capacity and span of the main girder, offering enhanced flexibility in installation layout and future expansion.

The anti-jamming end trucks on both sides of the main beam run along two parallel suspension runways perpendicular to the beam's direction. The crane is typically paired with an electric chain hoist for efficient lifting operations.

Main technical parameters

- Lifting capacity: 80kg-2t

- Span: <10m

- Control mode: ground control and remote control

Features

- Lifting capacity up to 2,000 kg

- Available in various track profiles and spans

- Enclosed track design effectively prevents dust buildup along the runway

- High-strength, cold-rolled steel track is lightweight, precise, and features a smooth rolling surface to minimize trolley wheel resistance

- Steel truss structure can be installed on any standard 15 cm thick reinforced concrete floor

Freestanding Crane System for Forklift Production Facility

Client Background & Requirements

A global forklift and intralogistics solution provider needed a lifting system for its new facility, serving both production and client demonstration.

Key needs:

- Clean, professional appearance to reflect brand image

- Expandable layout for future workstations and line extension

- Three zones: assembly, welding, logistics — covering full vehicle production flow

- Frequent handling requiring smooth, precise, and collision-free crane operation

Solution

- Installed freestanding workstation cranes across 58 workstations

- Equipped with 110 electric chain hoists (250 kg–2,000 kg)

- Enabled efficient, frequent handling across zones, reducing labor and increasing productivity

- Layout optimized for both function and presentation, with space reserved for future expansion

Client Feedback

“This is our flagship facility for both production and client visits. The system boosted efficiency, cut labor costs, and improved worker satisfaction. It's now our model workstation.”

Double Girder Freestanding Workstation Bridge Crane

The Double Girder Freestanding Workstation Bridge Crane is assembled from standard straight track sections and modular components, designed for handling heavier loads. It features a dual parallel girder structure, significantly enhancing load-bearing capacity and enabling the transport of large, heavy materials across wide spans.

An integrated double-girder trolley support allows the electric hoist to be positioned between the two girders, maximizing lifting height and improving vertical space utilization.

Main technical parameters

- Lifting capacity: 125kg-3t

- Control mode: ground control and remote control

Features

- High lifting capacity

- Enclosed track design prevents dust buildup; smooth rolling surface reduces trolley resistance

- High-strength, cold-rolled steel track is lightweight and precise

- Optimizes lifting height in space-constrained environments

Automotive Assembly Workshop Project

Client Background & Requirements

A leading automotive manufacturer needed a comprehensive lifting solution for its newly built assembly plant, facing the following challenges:

- Large work area requiring wide coverage and continuous operation

- Multiple production lines running concurrently without equipment interference

- Frequent handling of large, heavy components with strict demands on load capacity, efficiency, and safety

- Easy installation, flexible layout, and support for future expansion

Solution

A 3-ton double girder freestanding crane system was deployed, covering an area of 50 × 7 m, to efficiently support heavy-duty lifting and material handling.

- Full access to key work zones with reserved space for parts storage and logistics paths, optimizing plant layout

- Freestanding design enables line-to-line separation, enhancing production efficiency

- Quick assembly and adaptable layout support fast deployment and future reconfiguration

- Robust 3-ton double girder system ensures safe and stable lifting of large components

Headerless Freestanding Workstation Bridge Crane

The Headerless Freestanding Workstation Bridge Crane features a unique beam-free design, offering superior space efficiency and flexibility compared to traditional overhead systems. This structure allows the crane to operate under lower ceiling heights, reducing building construction costs while eliminating spatial restrictions caused by overhead beams.

It enables flexible production line layouts and supports lifting of various materials at individual workstations—without interfering with overhead cranes operating above the headerless system.

Motor Assembly Project

Client Background & Requirements

A motor manufacturing company urgently needed to improve assembly efficiency, facing several challenges:

- The facility lacked structural provisions for overhead cranes; traditional systems were inefficient, energy-intensive, and hard to maintain.

- Multiple workstations with frequent lifting required precise coverage of loading/unloading zones without interfering with existing overhead cranes.

- Heavy reliance on manual handling led to low efficiency, poor precision, and safety risks.

Solution

A customized 500 kg headerless freestanding crane system was implemented, paired with 500 kg electric chain hoists—delivering efficient, safe, and low-energy handling and assembly support.

User Feedback

After two years of operation, the client's production manager noted:

“The system has run flawlessly, completely solving our handling and assembly challenges. It improved efficiency, reduced labor, and ensured production flow. The headerless design is especially ingenious!”

Aluminum Alloy Freestanding Workstation Bridge Crane

The Aluminum Alloy Freestanding Workstation Bridge Crane features a high-strength, one-piece extruded aluminum main beam. Compared to steel rails of similar capacity, it is up to 40% lighter and requires only 45% of the operating force, enabling smoother, easier movement.

Aluminum offers higher machining precision and a smoother rail surface, reducing resistance and ensuring stable operation. The system's modular, compact design allows for easy integration and expansion. It can also be combined with steel tracks, reducing overall costs and saving valuable floor space.

Features

- Lightweight: Easy to install and handle, reduces transport costs and structural load on the facility

- High Strength: Low density with strong load-bearing capacity, ensuring safety and reliability

- Corrosion Resistant: Ideal for humid or corrosive environments, with low maintenance needs and broad industry applicability

- Aesthetic & Customizable: Smooth surface finish with flexible design options to enhance the workshop's appearance

Automotive Sheet Metal Workshop Project

Client Background & Requirements

A leading automotive manufacturer needed a solution for its sheet metal workshop (16 m × 7 m), where components weighing around 20 kg were manually handled for welding and transfer.

Manual handling led to low efficiency, frequent injuries, and damage to parts—prompting strong demand from frontline workers for improvement.

Solution

A 125 kg rail-mounted freestanding crane system was installed, featuring six main beams, electric chain hoists, and spring balancers.

- Full workstation coverage for multi-point welding and handling

- Freestanding design allows flexible deployment without reliance on building structure

- Rigid track ensures smooth, stable movement and prevents misalignment

- Lightweight operation with precise positioning, significantly reducing operator fatigue

- Compatible with welding tools and fixtures, enhancing both efficiency and safety

Freestanding Workstation Bridge Crane – Track Hanger Components

These hangers connect the supporting steel structure to the aluminum track and feature an adjustable-height design to compensate for elevation differences in the steel framework.

Based on application requirements, hangers are classified into rigid and flexible types, with key differences as outlined below:

| Item | Rigid Hanger | Flexible Hanger |

| Illustrative Diagram |  |

|

| Lifting Capacity | Supports higher loads (≤3 tons) | Lower lifting capacity (<2 tons) |

| Span | Allows longer spans, customizable beyond 9 meters | Shorter spans, typically less than 9 meters |

| Connection Method | Rigid bolt connection for structural integrity and stability | Spherical flexible connection allows limited swing movement |

| Positioning Accuracy | Excellent start-stop synchronization, high precision for accurate operations | Possible skewing or rebound during start/stop, lower positioning precision |

| Load Characteristics | Direct loading with full force transmission | Can absorb and reduce impact loads |

| Installation & Maintenance | More complex structure, higher material use, higher installation and maintenance cost | Simpler structure, fewer materials, easier installation and maintenance, lower overall cost |

DGCRANE has been deeply engaged in the crane industry for many years and is backed by a team of professional engineers. We can provide tailor-made workstation bridge crane solutions based on your plant structure, process layout, and material handling needs. Whether for a new facility or an existing workshop upgrade, we help you achieve efficient handling, cost savings, and optimized layouts.

Contact our engineering team today to get your customized design solution!