Ceiling Mounted Workstation Bridge Crane: Ideal for Tight Spaces and Complex Layouts

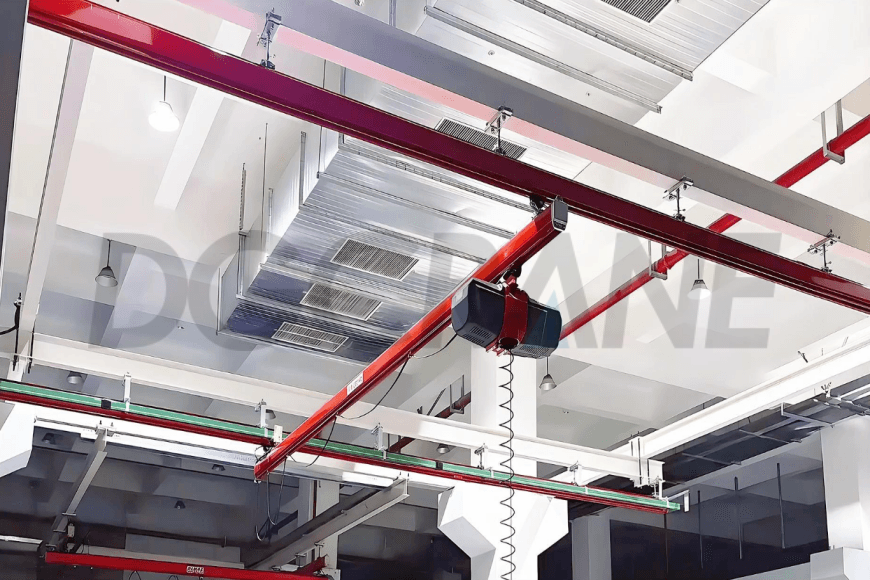

A ceiling mounted workstation bridge crane is an overhead lifting system installed directly on the ceiling structure. It uses strong slings to lift loads and operates through an electric motor or hydraulic system for lifting and horizontal movement. Since it does not occupy floor space, it is ideal for workplaces with limited ground area, such as factory workshops and warehouses. Suspension cranes offer high space utilization and flexible operation, and can be customized according to specific requirements.

Single Girder Ceiling Mounted Workstation Bridge Crane

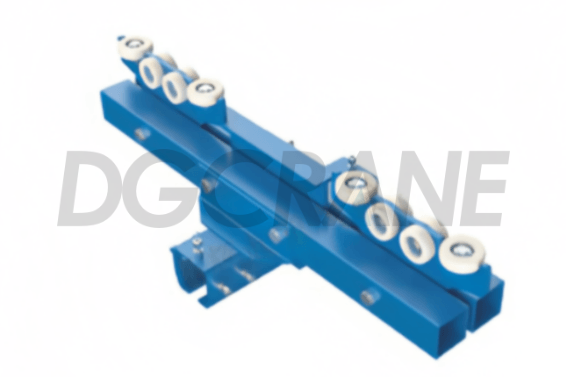

The single girder ceiling mounted workstation bridge crane is assembled using standard straight-track sections combined with auxiliary standard components. The end trucks of the main girder run on two parallel KBK suspension rails that are perpendicular to the main girder. The system is typically used in conjunction with a PK-type chain hoist, whose trolley travels along the direction of the main girder.

This product is designed for planar material handling and is suitable for environments such as workshops and warehouses. Thanks to its unique flexibility and freedom of movement, the single girder ceiling mounted workstation bridge crane can travel along inclined rails or rails with variable spans. The connection between the crane girder and its traveling mechanism uses universal ball joints, preventing jamming and allowing smooth movement through tapered rail sections and protrusions.

Key Features:

- Compact structure with minimal space requirements

- Trolley is coaxially aligned with the rail for smoother travel

- Cost-effective and ideal for single-operator use

- Typical lifting capacity ranges from 125 kg to 1000 kg

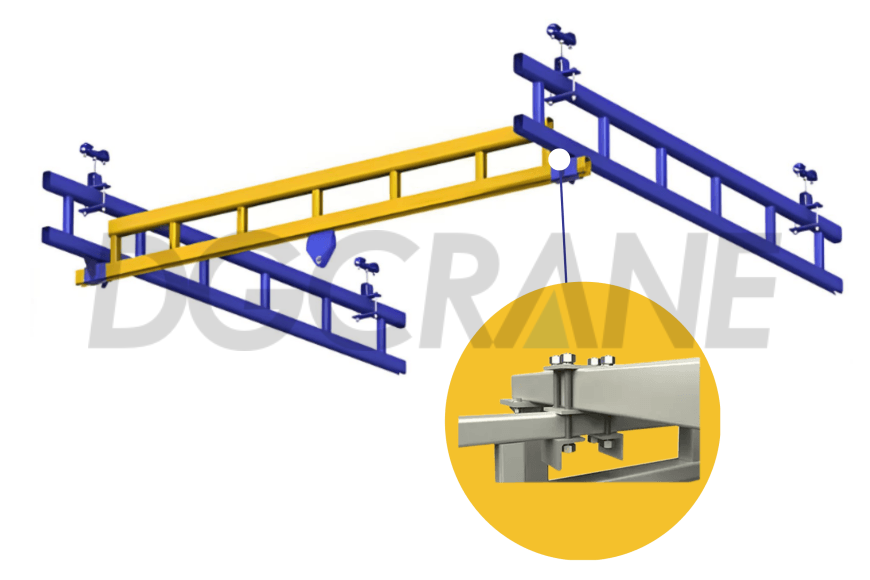

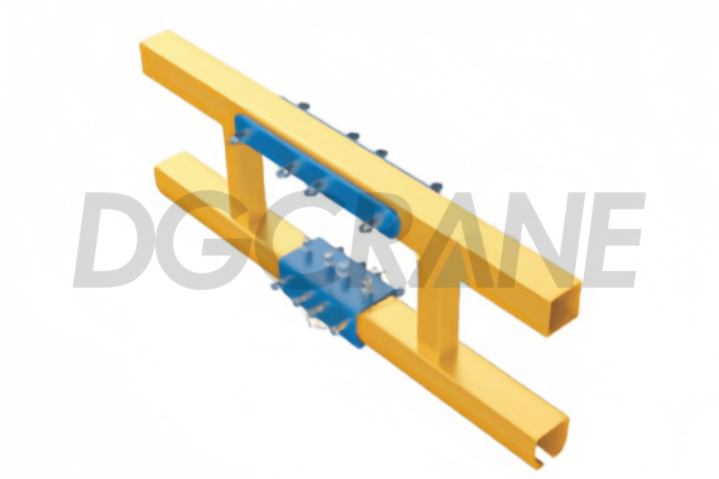

Double Girder Ceiling Mounted Workstation Bridge Crane

The double girder ceiling mounted workstation bridge crane is designed for handling heavier loads and is widely used for lifting heavy materials. The hoist is positioned between the profiles of the two main girders, maximizing the available lifting height. This product is suitable for planar material handling in workshops, warehouses, and other similar environments, and is commonly used for applications involving larger spans and heavier loads.

Key Features:

- Load capacity up to 2000 kg

- Better suited for medium to large span areas

- Double-girder structure enhances system rigidity and operational stability

- More flexible hoist travel path, allowing for more efficient operation

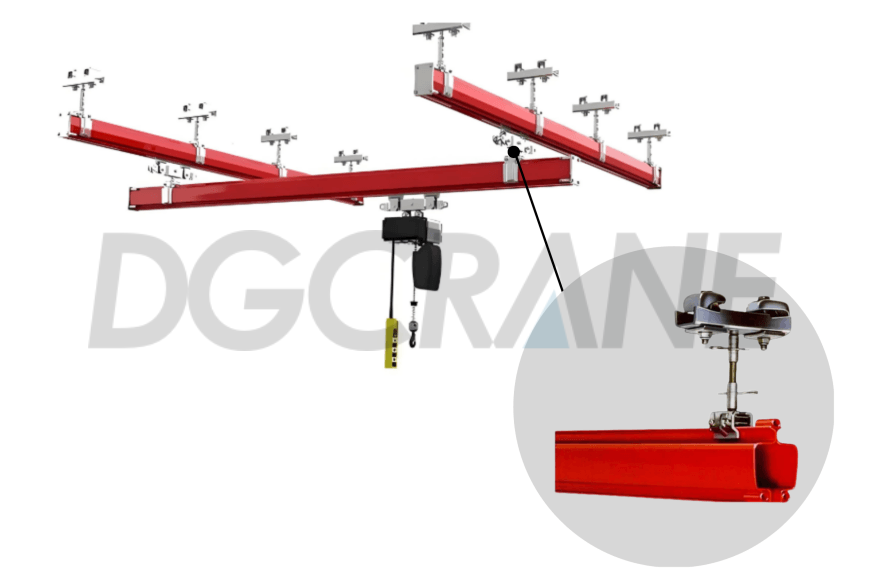

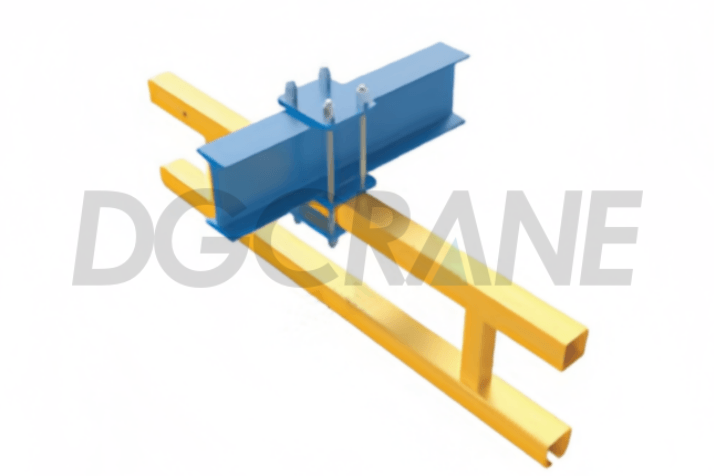

Telescopic Beam Ceiling Mounted Workstation Bridge Crane

The telescopic beam ceiling mounted workstation bridge crane is equipped with an extendable beam installed between or beneath the main girders. Depending on the design, the telescopic beam can extend beyond the crane runway on one or both sides. This configuration allows the crane to lift and position loads in hard-to-reach areas, such as between columns. Depending on the required extension width, the telescopic function can be achieved using KBK anti-lifting guidance components.

Key Features:

- Depending on the design, the main girder can extend beyond the runway width in one or both directions

- Enables accurate lifting and placement of loads in difficult-to-access areas (e.g., between structural columns)

- Maximizes workspace utilization (e.g., if the workshop is expanded in the future, the extended beam can reach new areas without adding more runway rails)

- Can operate underneath exhaust ducts, heating pipes, and electrical cables

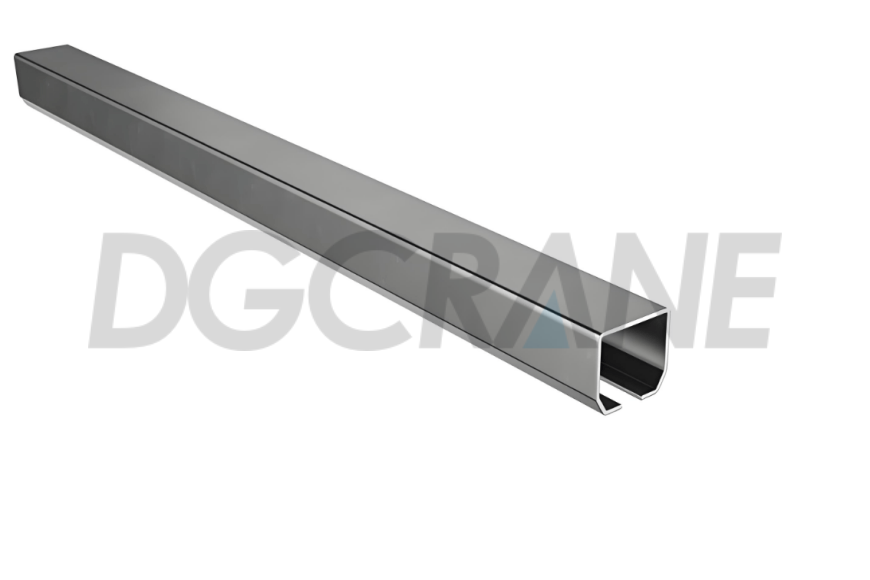

Aluminum Ceiling Mounted Workstation Bridge Crane

Aluminum ceiling mounted workstation bridge cranes equipped with aluminum alloy track systems offer excellent lightweight advantages. Manual travel is smoother, operation is easier, and the system has a sleek appearance with strong resistance to rust, making it especially suitable for cleanroom environments.

Key Features:

- Lightweight structure with low friction resistance

- Lower noise levels during operation

- Excellent corrosion resistance, ideal for humid or clean environments

- Easy to disassemble and assemble; maintenance-free system

Rigid vs. Flexible Crane Structures

Connection Type

Crane Track Design

- Rigid Ceiling Mounted Workstation Bridge Crane:

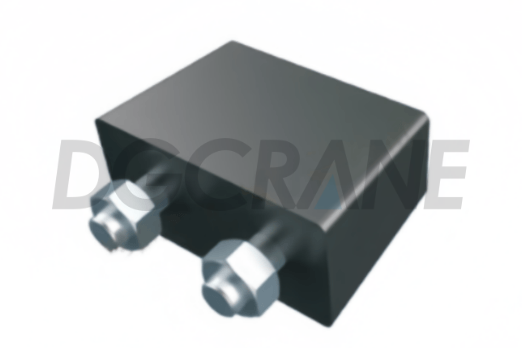

The tracks are typically made of C-shaped steel formed through a single cold-rolling process and connected using rigid joints. When one component experiences displacement or force, the connected component does not move or deform relative to the first one. A common connection method is direct fastening with steel plates and bolts. The track and the main girder are also locked together using sleeves for a firm connection. - Flexible Ceiling Mounted Workstation Bridge Crane:

The tracks are usually Ω-shaped, made by welding two steel plates together. Flexible joints are used, allowing connected components to move or rotate relative to one another. This type of connection does not restrict deformation in a particular direction.

Product Components

Rigid Ceiling Mounted Workstation Bridge Crane Modular System

Flexible Ceiling Mounted Workstation Bridge Crane Modular System

Operating Performance

- Rigid Ceiling Mounted Workstation Bridge Crane:

Offers relatively smoother operation with minimal vibration and sway. It provides higher positioning accuracy, making it suitable for applications that demand precise positioning, such as precision assembly tasks. - Flexible Ceiling Mounted Workstation Bridge Crane:

Requires less effort to start moving—when operated manually, pulling from one side causes the entire system to glide, and typically only about 0.4% of the load force is needed for operation. However, during movement, some sway and vibration may occur, and its positioning accuracy is slightly lower compared to rigid ceiling mounted workstation bridge crane systems.

Application

- Rigid Ceiling Mounted Workstation Bridge Crane:

Suitable for applications requiring high positioning accuracy, such as in the electronics, semiconductor, and precision instrument manufacturing industries. These scenarios demand precise handling and assembly of components. The rigid ceiling mounted workstation bridge crane track and suspension system offers superior positioning stability, minimizing sway and deviation during operation, and meeting the needs of high-precision production environments. - Flexible Ceiling Mounted Workstation Bridge Crane:

Ideal for environments where frequent changes in track layout are required or where the working conditions are complex and variable. In workshops with dense equipment or obstacles such as columns and pipelines, flexible ceiling mounted workstation bridge crane tracks can be routed around obstructions with ease, allowing efficient material handling without being constrained by spatial layout.

Whether it’s a standard single-girder structure or a more complex telescopic beam system, ceiling mounted workstation bridge cranes meet the demands of various industries for efficient, safe, and flexible lifting solutions through their modular design and outstanding performance. We offer a wide range of track materials, load capacities, and system expansion options to help you build a highly adaptable and cost-effective crane system. Feel free to contact us for customized solutions and selection support.