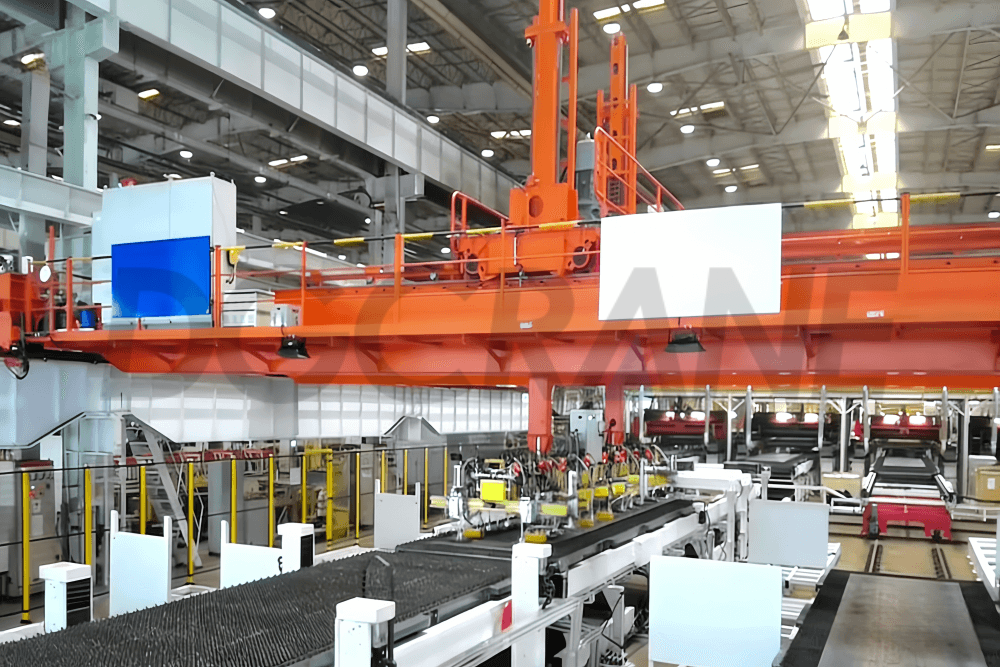

Automated Steel Plate Handling Overhead Crane: Applications in Steel Storage & Warehouse Operations

Automated steel plate handling overhead cranes are indispensable material handling equipment in the continuous casting and rolling process of metals, mainly used for transporting finished products and steel plates in storage areas or warehouses. This type of crane operates in a high-speed production environment and requires a reliable and continuous power supply to ensure smooth and precise material handling.

- Capacity: 5t-32t

- Span: 22.5m-28.5m

- Lifting height: 6m-12m

- Lifting speed: 10-40m/min

- Trolley traveling speed: 20-60m/min

- Crane traveling speed: 32-120m/min

- Steel plate width: 1m-2.5m

- Steel plate length: 6m-12m

- Handling cycle time: 1 sheet per 3 minutes.

Automated steel plate handling overhead crane’s features

- Fully automated operation enables multi-functional, unmanned operations such as loading and unloading, handling, stacking, sheet splitting, and warehousing, thereby reducing the overall material handling time.

- Blow-to-hook devices use vacuum lifters or electromagnetics to minimize damage to finished sheet metal products.

- Millimeter-level high-precision positioning, with a positioning accuracy within ±5mm, strictly matches process requirements and improves production efficiency.

- Unmanned intelligent material handling, in collaboration with the production workshop scheduling and management system, ensures work efficiency and process control.

- Full-process traceability enables the timely acquisition of material handling information, preventing various unexpected failures and reducing downtime.

Special lifting device for steel plate handling

Electro-permanent magnet lifting device

When energized, the magnetic field generated by the electromagnetic coil is superimposed on the permanent magnet, enhancing the attraction force; after the power is turned off, the magnetic field of the permanent magnet still exists, ensuring that the object is stably suspended.

The features of the electro-permanent magnet lifting device:

- Multiple electromagnetic lifting devices, with multi-level magnetic adjustment functions, precisely control the magnetic penetration depth of the lifting gear, ensuring efficient steel plate handling.

- The lifting system is equipped with identification data for different types of steel plates, thereby applying the corresponding magnetic attraction force to steel plates of different sizes.

- A gravity sensor is installed on the lifting gear shaft to analyze steel plates of different weights, prevent uneven stress, and ensure safe handling.

Other optional lifting device

Vacuum suction cup

Air is extracted from the suction cup cavity to create a vacuum environment. At this point, the air pressure outside the suction cup is much greater than the air pressure inside. It primarily utilizes the pressure difference between the inside and outside of the suction cup to attract and adhere objects.

The features of the vacuum suction cup:

- Equipped with a double-ear lifting beam and a vacuum pump, it ensures the steel plate remains stable during handling and prevents material breakage.

- The rubber suction cup has a large contact surface, and it can instantly adsorb after forming a negative pressure, thus improving handling efficiency.

- It also features a vacuum accumulator and an audible alarm to ensure safe and reliable handling.

As a core equipment for high-speed metal casting and rolling lines, DGCRANE's Automated Steel Plate Handling Overhead Crane integrates high-precision positioning, intelligent unmanned operation, and flexible lifting solutions—whether you choose electro-permanent magnet or vacuum suction cup devices, it ensures safe, efficient, and traceable steel plate handling. Let our reliable automated cranes power your production line forward.