Overhead Crane Operation Safety Rules: Key Standards for Safe and Compliant Operations

Table of Contents

Ensuring the safe operation of overhead cranes is not only essential for protecting employees’ safety and health, but also for maintaining production continuity, extending equipment lifespan, and ensuring legal compliance. Relevant domestic and international regulations and standards provide important guidance for the safe operation of overhead cranes. These include China's GB/T 6067 Safety Rules for Cranes, the U.S. OSHA 1910.179, and international standards such as ISO 9927. The implementation of these standards helps enterprises reduce accident risks and improve production efficiency.

Overhead Crane Operation Safety Rules

To ensure the safe operation of overhead cranes in practical applications, various countries and regions have established corresponding regulations and standards. Understanding these standards is key to ensuring compliance and safe operations.

GB/T 6067 Safety Rules for Cranes (China)

This is one of the most important safety operation standards for overhead cranes in China. It outlines the safety requirements for crane operation, installation, and inspection, covering operator qualifications, equipment safety limits, and protective measures during operation.

Regulations on the Supervision of Special Equipment (China)

This regulation serves as a crucial legal basis for the supervision and management of special equipment, including overhead cranes, under China's legal framework. It mandates that all stages of the crane's lifecycle—design, manufacturing, installation, operation, maintenance, and decommissioning—must comply with national safety standards. Enterprises are responsible for providing operators with necessary safety training and conducting regular inspections and maintenance of lifting equipment.

OSHA 1910.179 (United States)

Issued by the Occupational Safety and Health Administration (OSHA), the 1910.179 standard is a mandatory requirement for the operation of overhead and gantry cranes. It is widely applied in the manufacturing and construction industries. The standard sets strict requirements for the use of overhead cranes, especially concerning operator training, routine equipment inspections, and control of the operating environment.

ISO 9927 (International)

Published by the International Organization for Standardization (ISO), the ISO 9927 standard focuses primarily on the periodic inspection of cranes and operator requirements. It emphasizes operator certification and scheduled inspections to ensure that cranes remain in a safe working condition during operation.

Key Points of Safe Operating Procedures for Overhead Cranes

Implementing safe operating procedures for overhead cranes requires thorough preparation and effective management across multiple aspects. The following are the key points for ensuring safe crane operations:

Operator Requirements and Qualifications

Reference: GB/T 6067 Safety Rules for Cranes

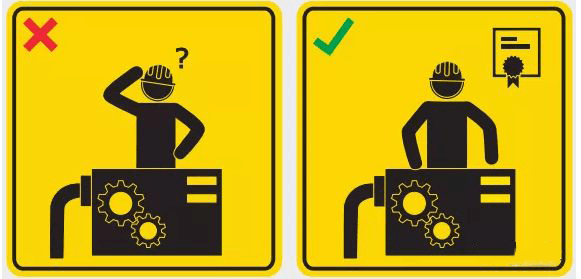

Operators are at the core of overhead crane safety. According to GB/T 6067 and OSHA 1910.179, overhead crane operators must undergo specialized technical training and obtain proper certification before they are allowed to operate the equipment.

This training typically includes:

- Basic principles of crane operation

- Practical operation skills

- Emergency response measures

Qualified operators must be able to operate the equipment skillfully, respond effectively to emergency situations, and understand how to ensure safety under various working conditions. After initial training, operators are required to undergo regular re-education and assessments to maintain a high level of competence in day-to-day operations.

Operator Responsibilities

Reference: GB/T 6067 Safety Rules for Cranes

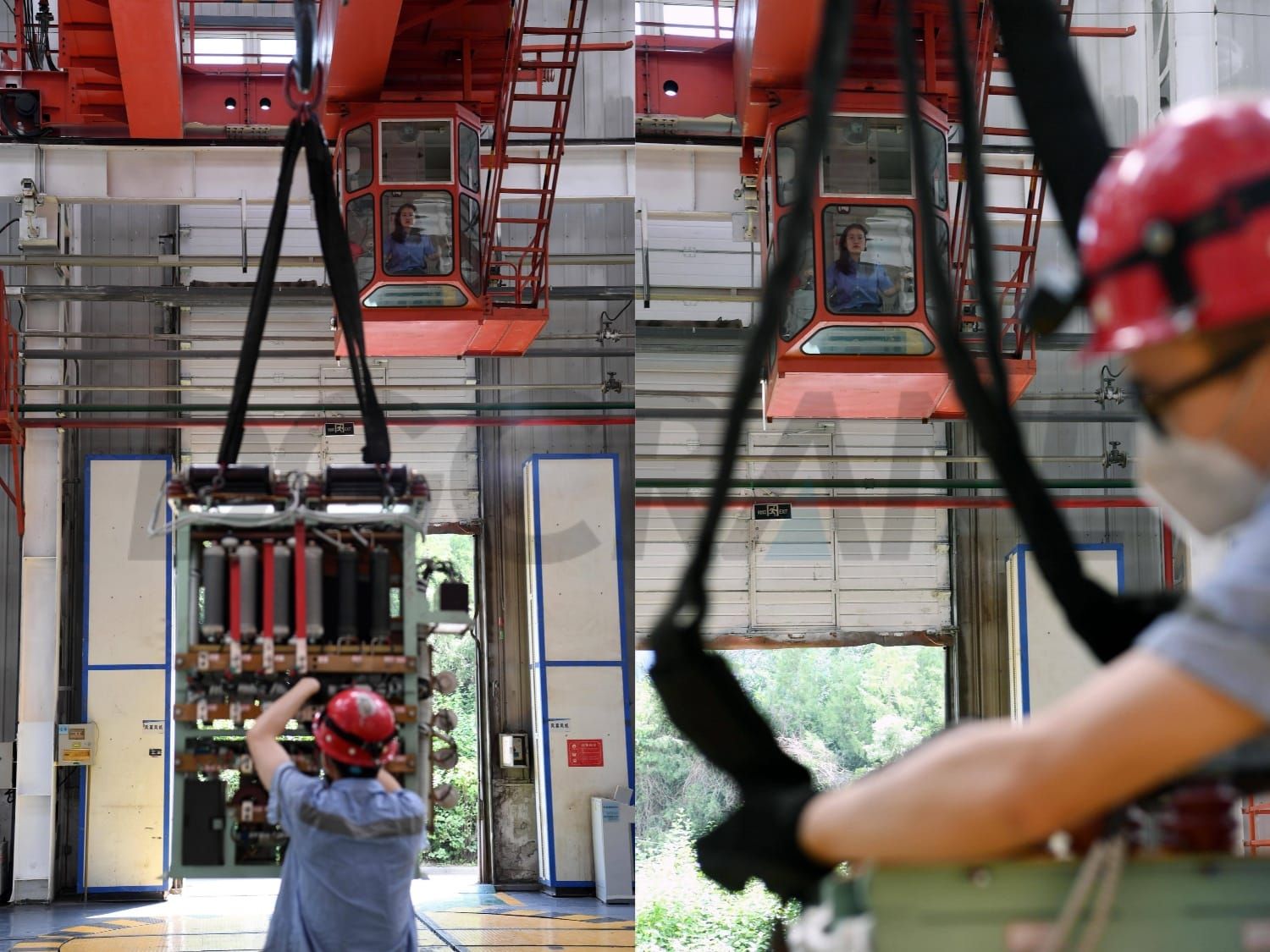

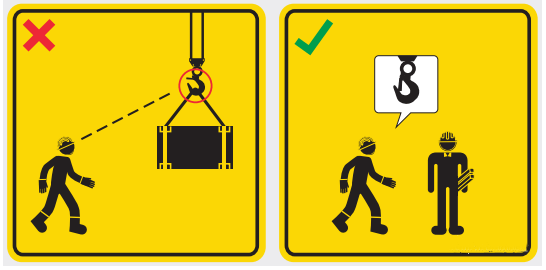

Operators must follow the manufacturer's instructions and adhere to workplace safety policies to ensure the safe operation of the crane. Except in the case of receiving a stop signal—which must always be obeyed—operators should follow clearly identifiable signals from designated riggers or signalers.

Operators should meet the following criteria:

- Possess the required educational background

- Be at least 18 years old

- Have adequate vision, hearing, and reflexes to safely perform the job

- Be physically fit to operate lifting machinery

- Have the ability to judge distances, heights, and clearances

- Be professionally trained on the crane being operated, with strong knowledge of its safety devices

- Be trained in lifting operation hand signals and capable of understanding and following rigger or signaler commands

- Be familiar with onboard fire extinguishing equipment and trained in its use

- Be knowledgeable in emergency response procedures and evacuation methods

- Hold valid crane operation qualifications (excluding training operations under professional supervision)

Note: The validity period of the health certificate confirming fitness for crane operation must not exceed five years.

General Requirements for Safe Crane Operation

- Operators must not engage in distracting activities while operating the crane

- Cranes must not be operated if the operator is physically or mentally unfit

- Operators must follow lifting signals from designated personnel. If no signaler is used, the operator is fully responsible for the lifting task

- Stop signals from anyone must be obeyed immediately, regardless of the source

- Operators are responsible for all actions directly under their control. If any unsafe condition is suspected, the operator must consult with management before proceeding with the lift

Daily Operating Requirements for Overhead Cranes

Reference: GB/T 6067 Safety Rules for Cranes

To ensure equipment stability and load safety, operating an overhead crane must strictly follow standardized procedures. Below are the essential safety and operational requirements based on GB/T 6067 Safety Rules for Cranes and other established practices:

General Safety Requirements for Crane Operation

- Operators must not engage in any distracting tasks while operating the crane.

- Cranes must not be operated if the operator is physically or mentally unfit.

- The operator must follow lifting signals issued by designated personnel. If no signaler is used, the operator is fully responsible for the lifting operation.

- Stop signals from any person must be followed immediately, regardless of who gives them.

- Operators are responsible for actions under their direct control. If they suspect an unsafe condition, they must consult with management before proceeding with the lift.

Pre-Lifting Inspection and Setup

Before initiating a lift, operators should ensure the following:

- Wire ropes or lifting chains must not be twisted or kinked.

- Multiple wire ropes or chains must not be entangled.

- Loads lifted with hooks should rotate as little as possible.

- If slack ropes are observed, they must be adjusted to eliminate looseness on drums or pulleys.

- Wind effects on the load and crane should be taken into account.

- The load must not be stuck or connected to other objects.

Precautions During Lifting Operations

- Avoid sudden acceleration or deceleration when lifting loads.

- The load and wire rope must not scrape or collide with obstacles.

- Cranes without reverse braking capability must not be stopped by reversing the motor, except in emergencies.

- Side-pulling or dragging of loads is strictly prohibited (unless the crane is designed for such operations).

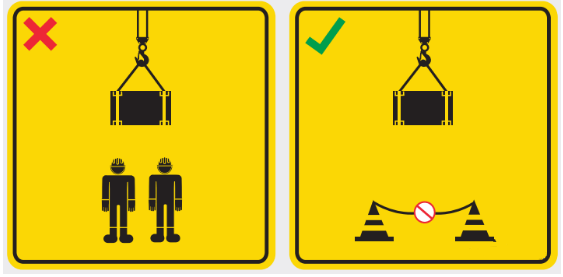

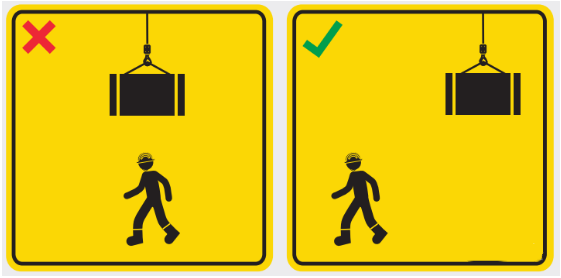

- Never move loads over personnel.

- When lifting near the rated capacity, lift slowly and perform a test lift slightly off the ground to verify brake performance.

- Avoid sudden starts or stops when rotating, luffing, or traveling. Control the lifting speed to keep the load swing within safe limits. Use warning signs or visual markers if swinging poses a risk.

Restricted Zones and Prohibited Actions

- No person should stand beneath a suspended load.

- No operations should be performed until the load is fully lowered to the ground.

- Operators and support personnel must stay outside the crane's working radius to avoid collision or falling load accidents.

Securing the Crane When Unattended

Before leaving the crane unattended, the operator must:

- Lower the load completely to the ground—never leave it suspended.

- Engage brakes or set safety locks on travel mechanisms.

- Raise lifting gear to the designated height.

- Disconnect the power supply or disengage the main clutch, if applicable.

- Set all control handles to the “zero” or neutral position.

- Secure the crane to prevent accidental movement.

- If engine-powered, turn off the engine.

- For outdoor cranes, use rail clamps or equivalent devices to secure the crane during strong winds or when out of operation.

- If warning signals indicate issues with the power disconnect device or starting control, the operator must not start the crane until authorized personnel clear the alarm.

- Before energizing or operating the crane, ensure all controllers are in the “zero” or neutral position and that all personnel are in safe zones.

Handling the Load

Reference: OSHA 1910.179

Proper handling of loads is critical to the safe operation of overhead cranes. The following key practices, derived from OSHA 1910.179, help ensure safe and stable load movement:

Centered Loads: The load must always be positioned directly beneath the hoist hook to prevent side pulls. Side pulling introduces dangerous lateral forces that can damage equipment or lead to structural failure.

Raising the Load: Loads should be hoisted vertically in a controlled and smooth manner. Any deviation can cause the load to swing or move uncontrollably, increasing the risk of accidents.

Securing the Load: Operators must never carry loads over personnel or active work areas. This reduces the risk of serious injury in the event of load drop or equipment failure.

Stopping Movement: Sudden stops, starts, or directional changes should be avoided. These actions can compromise the stability of the crane and the load, leading to unsafe conditions.

Avoiding Obstructions: During operation, both the crane and the load must be moved in a way that keeps the travel path clear of obstacles, structures, or other equipment. This minimizes the chance of collisions or entanglements.

Safety Devices and Inspection Methods for Overhead Cranes

Reference: ISO 9927

Ensuring the safe operation of overhead cranes relies heavily on the proper functioning of protective safety devices and the implementation of rigorous inspection protocols. These measures work together to detect potential hazards in advance and prevent accidents caused by equipment failure or human error.

Key Safety Devices

Anti-collision Systems

Prevent cranes from colliding with obstacles or other cranes in multi-crane environments. These systems can automatically slow down or stop the crane when a risk of collision is detected.

Limit Switches

Limit the range of motion in hoisting, traversing, or traveling directions to prevent over-travel or mechanical overstress. Common types include:

- Hoisting limiters (upper/lower hook position)

- Travel end-limit switches

- Slewing or luffing range limiters

Overload Protection Devices

Automatically halt hoisting operations if the load exceeds the crane's rated capacity, thus preventing structural or mechanical failure. These systems help safeguard both equipment and personnel from overload risks.

Inspection Methods

Routine inspections are critical to ensuring cranes remain in safe working condition. ISO 9927 outlines multiple inspection methods:

Visual Examination

- Every component of the crane should be visually inspected for abnormalities or deviations from standard conditions.

- Methods may include visual checks, hammer testing, or dimensional measurements.

- Normally conducted without dismantling, but partial disassembly may be required if issues are suspected.

Non-destructive Testing (NDT)

- If visual inspection reveals potential issues, non-destructive testing should be conducted, including:

- Dye penetrant testing

- Ultrasonic testing

- Magnetic particle testing

- Radiographic (X-ray) testing

- Acoustic emission testing

- These methods detect cracks, corrosion, or material fatigue that may not be visible on the surface.

Functional Testing

- All controls, switches, and indicators should be checked for proper function.

- Electrical or hydraulic systems should be tested as needed.

- Key devices to be tested include:

- Rated capacity limiters and indicators

- Motion limiters (e.g., travel, slewing, luffing)

- Performance indicators

No-load Test

- Performed at rated speeds for all crane motions (e.g., hoisting, traveling, slewing) without a load.

- Purpose: to detect abnormal sounds, vibrations, or response delays.

Load Test

- Conducted with a test load (not exceeding rated capacity unless required by local legislation).

- Tests hoisting, traveling, traversing, and slewing motions under real load conditions.

- Used to verify the crane's performance under actual working conditions.

- Load test frequency must comply with local laws and safety regulations.

Note: Some national standards may require a test load that exceeds the rated capacity for safety margin verification.

Emergency Response and Safety Devices for Overhead Cranes

Reference: ISO 9927 and OSHA 1910.179

During the operation of an overhead crane, various emergency situations may occur — such as mechanical failure, load loss of control, or sudden power outage. To manage these risks, both ISO 9927 and OSHA standards require overhead cranes to be equipped with emergency braking systems and other emergency response devices. Operators must be fully trained and prepared to respond swiftly and safely to such incidents.

Emergency Equipment and Operator Preparedness

- Cranes must be fitted with emergency stop switches, braking systems, and power cut-off devices.

- Operators must be trained to immediately activate emergency devices to stop the load movement and, if possible, safely lower the load without increasing risk.

- The main power disconnect switch should be clearly marked and easily accessible for fast shutdown during emergencies.

Power Failure During Operation

- Engage the brake or activate another safety mechanism to prevent unintended movement.

- Disconnect all power sources or shift the clutch to a neutral position.

- If feasible, use manual control of the brake to safely lower the suspended load to the ground.

- Ensure the load is properly secured using slings or rated lifting devices — do not use bolts or steel wire rope to link chains.

- Avoid dragging chains or slings along the ground.

Equipment Malfunction

- Immediately stop operations and shut off the main power supply.

- Resume work only after the issue has been diagnosed and resolved by qualified personnel.

Loss of Load Control

- The operator must stay calm, activate a warning signal, and immediately shut down the main power.

- Ground personnel must evacuate the load's path.

- If the hoisting mechanism brake fails and the hook or load drops quickly:

- Use the “jogging” method or reverse motion control to analyze the fault.

- If it's a mechanical brake failure, repeatedly attempt to lift the load and move it to a safe area before lowering it. Shut off power and report for maintenance.

- If it's an electrical brake failure, engage the emergency switch, shut off main power, and call for repair.

Electrical Fire Response

- Immediately shut off the main power.

- Use a CO₂ or dry powder fire extinguisher.

- If extinguishing a live electrical fire, maintain a safe distance:

- For voltages up to 10kV: minimum 0.4 meters

- For voltages 35kV and above: minimum 0.9 meters

- When using CO₂ extinguishers, ensure good ventilation, maintain a 2–3 meter distance, and avoid direct contact with dry ice on the skin.

Electric Shock Incidents

- Immediately cut off the main power supply.

- If the victim might fall when released from the current, take precautions to prevent secondary injuries.

- After disconnecting power, perform CPR or first aid, and call emergency services immediately.

Serious Accidents or Injuries

- Shut off the main power switch.

- Secure the accident site.

- Report the incident to workshop supervisors immediately.

Conclusion

The safe operation of overhead cranes is a core component of industrial safety management. Whether following national standards such as GB/T 6067 or international regulations like OSHA 1910.179, these frameworks provide clear operational guidelines and legal foundations for crane safety.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!