6 Critical Overhead Crane Accidents and How to Prevent Them

Table of Contents

In modern industry, lifting machinery is indispensable equipment, widely used in construction, manufacturing, transportation, and other sectors. It can efficiently handle heavy materials and boost productivity. However, due to the complexity of cranes and the high precision required in their operation, safety issues become especially critical.

OSHA estimates that 93% of crane accidents are caused by human error. Think about that. In other words, equipment failures do occur, but the vast majority of accidents result not from the equipment itself, but from issues like misjudging loads, violating operating procedures, or neglecting routine maintenance. Overhead crane accidents can not only damage equipment but also lead to injuries, fatalities, and significant property losses. Therefore, it is crucial to understand the common causes of crane accidents and take effective preventive measures.

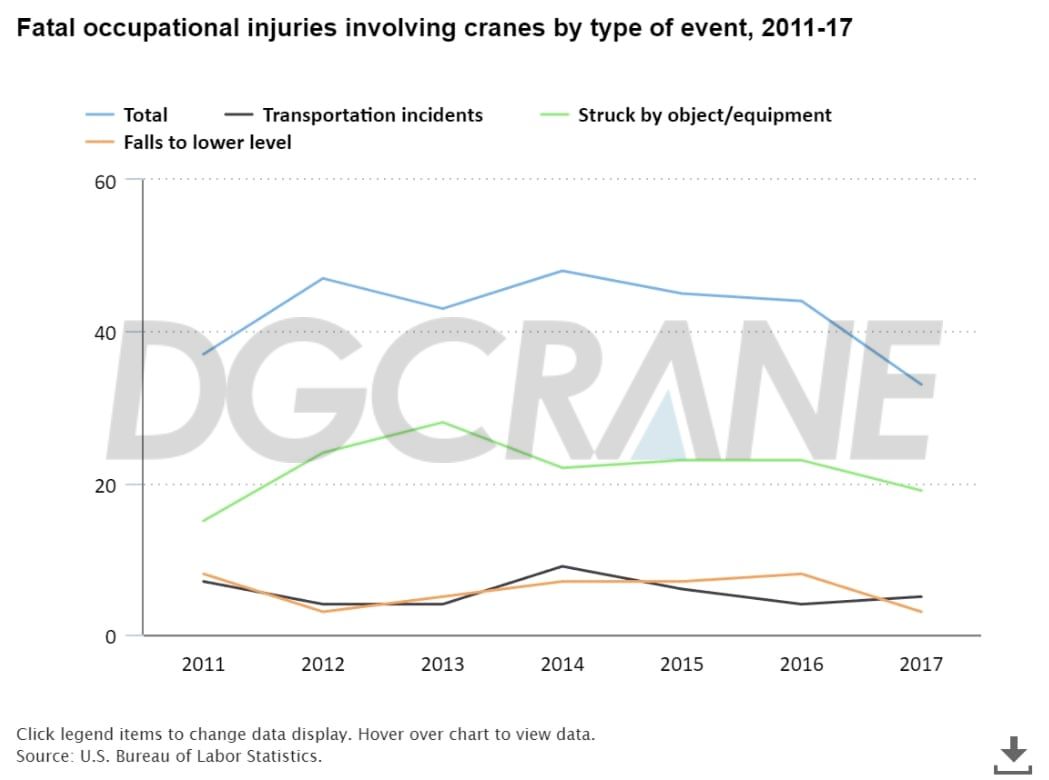

According to the Census of Fatal Occupational Injuries (CFOI) by the U.S. Bureau of Labor Statistics, from 2011 to 2017 there were 297 crane-related fatalities, averaging 42 deaths per year linked to cranes.

Unhooking Accidents

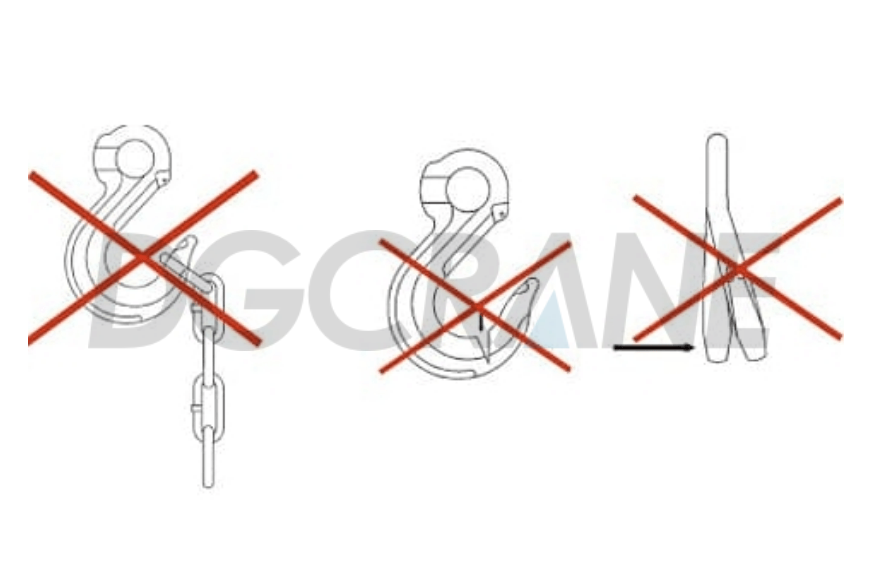

This refers to accidents where the lifted load, slings, or lifting gear slip out from the crane hook, causing them to fall. The main causes are failure of the hook's safety latch or improper slinging methods.

Causes:

- When lifting objects, the hook descends too quickly due to lack of on-site signaling, leading to unhooking.

- If the lifted object is unstable, the hook may swing in the air; during the swing, centrifugal force can throw the hook off, causing it to unhook.

- Improper crane operation, sudden starts, or emergency braking can also create inertia that forces the hook head out.

- For cranes with both main and auxiliary hooks, if the unused hook is placed on a small loop of the sling, the thick hook may not fit securely; vibrations and swinging can cause centrifugal force to dislodge the hook, leading to falling accidents.

Preventive Measures

- Store hooks in a dry environment after use, avoiding contact with corrosive chemicals like acids and alkalis; perform regular inspections.

- Lubricate hooks regularly.

- Hooks are primarily used as connecting tools in lifting operations; their working load and scope of application should be based on testing and specifications. Overloading is strictly prohibited.

- When used in combination, pay attention to the lifting angle to keep the load balanced.

Falling Loads (Lifting Gear)

| Issue | Cause Analysis | Control & Preventive Measures |

| Improper Binding and Slinging | Excessive wire rope angle without balance beam causes breakage. Sharp edges without protection cut wire ropes, leading to load falls and injuries. |

Use proper binding and slinging methods. Strictly follow “Ten No-Lifting Rules.” Ensure dedicated supervision and signaling. Enforce correct sling techniques and qualified personnel management. |

| Defective Lifting Gear & Slings | C-hooks missing safety pins. Hook fractures. Wire rope breaks cause load drops and injuries. |

Inspect C-hook pins, hooks, and wire ropes before lifting. Conduct daily inspections and immediately replace damaged parts. Maintain and lubricate hoisting equipment regularly. |

| Hoisting Mechanism Defects | Drum fractures. Brake failure. Malfunctioning operating mechanisms cause load drops and injuries. |

Check drums, brake linings, and mechanisms before use. Perform daily checks on components and limit switches. Ensure mechanical and electrical parts are maintained and lubricated. |

Crane Collision Accidents

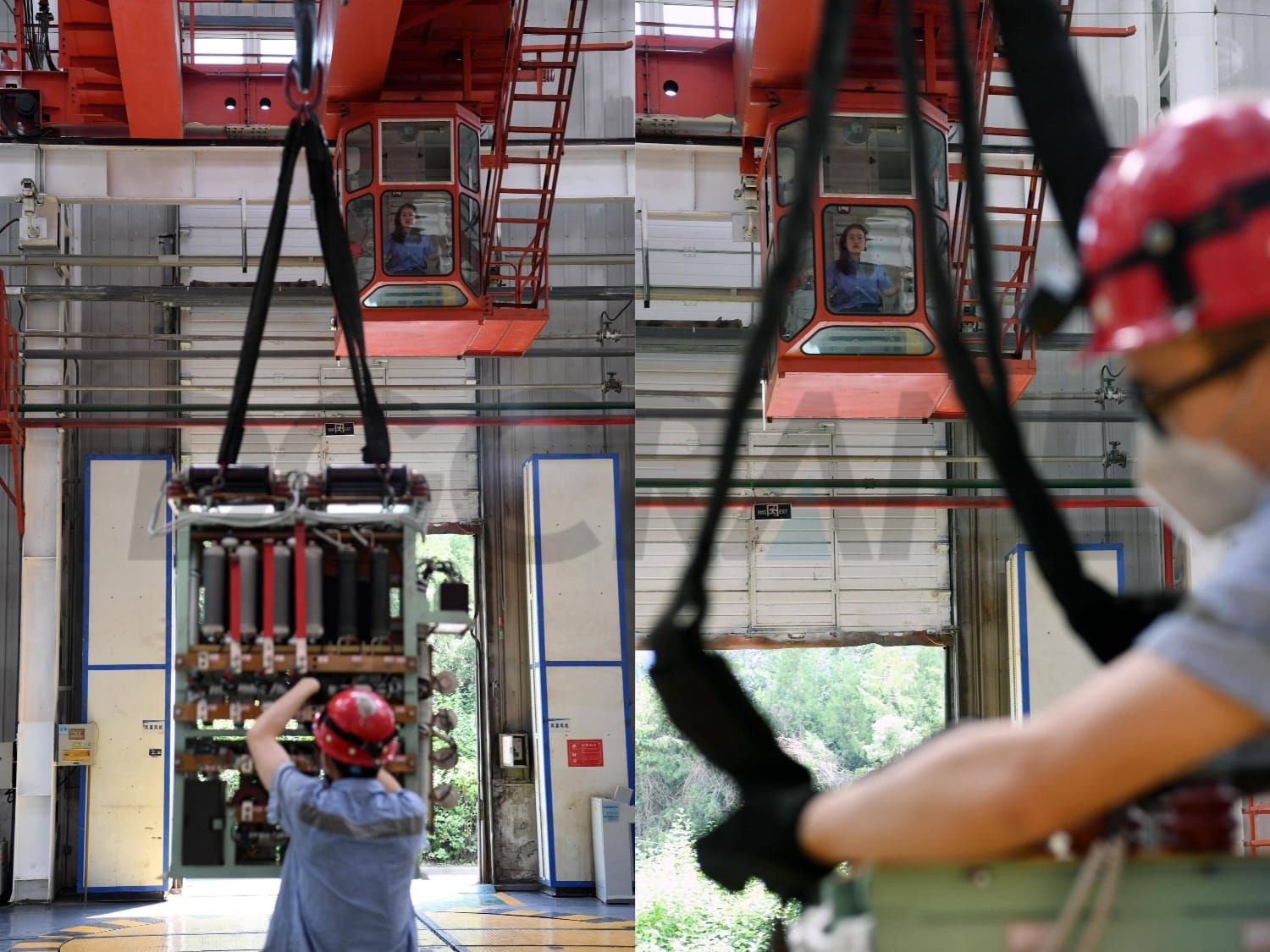

Crane collisions are among the common hazards in lifting operations, mainly caused by limited operator visibility, unclear communication, and crane misalignment. To mitigate these risks, a series of effective preventive measures must be adopted. Below is a detailed explanation of these causes and corresponding preventive strategies.

Causes of Crane Collisions

Limited visibility

The operator's cab is typically elevated, and the view is often blocked by structural components such as the boom, hook, or the load itself. This restriction makes it difficult to fully monitor the working area, especially in tight spaces with many obstacles, creating blind spots that may hide equipment, barriers, or personnel and increase collision risk.

When moving large or irregularly shaped loads, the operator's view can be further obstructed by the load itself, making it even harder to judge the surrounding environment and increasing operational risk.

Unclear communication

Poor communication often occurs in noisy environments or when operators and signalers lack training in standardized hand signals. Ambiguous or delayed signals may cause misunderstanding, leading to unsafe operations. If the operator cannot clearly receive instructions, it may result in incorrect lifting actions, raising the likelihood of collisions—particularly in complex, multi-person tasks.

Preventive Measures

Clear communication

Establishing clear and reliable communication channels is crucial. Operators and signalers should use standardized hand signals, radio communication, or other tools to ensure messages are conveyed promptly and accurately. In limited-visibility conditions, ground signalers should guide and monitor the operation effectively. Faulty or unstable communication devices must be promptly checked or replaced to avoid external interference.

Enhanced visibility

To improve visibility, cameras or other auxiliary devices should be installed in the crane cab, enabling operators to monitor the load and surrounding area in real time. These tools help identify obstacles in blind spots and provide a broader field of view during load movement, which is especially valuable when handling large or complex objects.

Electric Shock Accidents

During the operation of overhead cranes, electric shock is a common cause of fatal accidents, especially when working near high-voltage lines or other live conductors. The risk of electric shock increases significantly if the crane operates too close to power lines, particularly when the equipment has poor insulation.

To prevent such incidents, operators must always maintain a safe distance between the crane and power lines—typically at least 10 feet, with the exact distance depending on the voltage level. Additionally, using tools and equipment with proper insulation effectively reduces the risk of electric shock. Where possible, power to nearby lines should be disconnected before starting operations to ensure a safer working environment.

Mechanical Failure Accidents

During the operation and maintenance of lifting machinery, damage and failure of several key components are often major causes of safety accidents. The following table outlines common failure analyses and corresponding preventive measures for critical parts such as hooks, wire ropes, reducer gears, drums and rope clamps, and brakes. This helps crane operators better understand essential maintenance points to ensure safe operations.

| Component | Problem Analysis | Preventive Measures |

|---|---|---|

| Hook | 1. Hooks may get damaged, crack, deform, or fracture due to overloading or friction. 2. Hook breakage can cause serious accidents. 3. Wear at the opening and critical cross-sections is common in lifting operations. |

1. Strictly prohibit overloading. 2. Regularly inspect critical cross-sections and opening wear. 3. Perform periodic annealing. 4. Scrap hooks with cracks as per standards; welding repairs are strictly forbidden. 5. Usability must be checked regularly by certified personnel and hooks used only if they meet standards. |

| Wire Rope | 1. Endures complex stresses: tension, compression, bending. 2. Overloading and repeated winding increase damage and risk of breakage. 3. Excessive winding on drums/pulleys further raises failure risk. 4. Load condition depends on work type, drum diameter, pulley condition, and maintenance. |

1. Select ropes suitable for work environment and type. 2. Always operate within rated load. 3. Avoid sudden impacts. 4. Regularly lubricate, especially under harsh conditions. 5. Use protective devices in corrosive or high-temperature environments. |

| Reducer Gears | 1. May show wear, pitting, scoring, or tooth breakage under torque. 2. Caused by rough surfaces, poor lubrication, shock loads, overloading, fatigue from repeated bending, or hard particles causing wear. |

1. Replace lubricant regularly and keep gearbox clean, using proper lubricant. 2. Operate smoothly, avoiding sudden reversals or abrupt stops. 3. Check lubricant cleanliness regularly and replace contaminated oil promptly. |

| Drum & Rope Clamps | 1. Drums wear, pit, or thin due to friction/compression from the rope. 2. Severe thinning can cause fractures as the drum can't handle operational stress. |

1. Replace drum if wear exceeds 20% of original wall thickness or if cracks appear. 2. Regularly lubricate drums and ropes to reduce wear. 3. Keep work environment clean to avoid accelerating drum damage. |

| Brake | 1. Common failures: brake not working, insufficient braking force, failing to release, high brake wheel temperature. 2. Causes: weakened springs, stuck electromagnets, worn or detached linings, worn brake wheels/belts, poor lubrication or contamination. 3. Failures in hinges, push rods, or air in hydraulic cylinders also lead to malfunction. |

1. Inspect brake each shift. 2. Check brake wheels and belts for wear to ensure function. 3. Check hydraulic systems regularly for air ingress or oil shortage. 4. Replace worn parts promptly; keep all moving parts functional to avoid sticking. 5. Ensure lubrication meets operational standards with routine checks. |

For more details, please refer to the original article from DGCRANE: Overhead Crane Troubleshooting: Common Failures, Solutions, and Maintenance Tips

Operator Errors

Overhead cranes play a critical role in industrial production. However, due to the complexity and high-risk nature of their operation, accidents still occur. Among these, human error remains one of the leading causes, often resulting from poor judgment, insufficient training, or fatigue, which can lead to unsafe operating behaviors.

Cause Analysis

Lack of experience

Insufficient training or limited practical experience is a common source of operator errors. Without fully understanding the crane’s operating characteristics or load limits, operators may misjudge whether the crane can safely lift or move a load. For example, attempting to handle loads beyond rated capacity can damage equipment or cause injuries.

Fatigue or distraction

An operator's physical and mental condition is crucial for safe crane operation. Fatigue or distraction significantly increases the risk of mistakes. Long hours or loss of focus may lead to misreading signals, resulting in uncoordinated or delayed movements. For instance, a distracted operator might overlook people beneath the load, creating serious hazards.

Ignoring safety procedures

Failing to follow established safety protocols is another major cause of accidents. Skipping standard checks or neglecting to follow correct signaling procedures often leads to unsafe operations. In particular, unclear or improper signaling can directly trigger crane accidents and is often underestimated.

Preventive Measures

Comprehensive training

Thorough training is essential for inexperienced operators. Training should combine theoretical knowledge and practical exercises to ensure operators master safe operating skills. Ongoing advanced training helps keep skills up to date. For example, regular emergency drills can prepare operators to respond effectively under pressure.

Preventing fatigue

Reasonable work scheduling ensures operators remain alert and focused. Measures such as shift rotation and proper rest can help reduce fatigue-related errors. Additionally, intelligent monitoring systems can detect signs of operator fatigue in real time, helping to prevent accidents before they occur.

Strict compliance with safety procedures

Operators must strictly follow established safety guidelines. Crane operators should aim for five principles:

- Steady: Smooth starts and stops to keep hooks and loads stable.

- Accurate: Place loads precisely at target locations.

- Efficient: Coordinate movements to reduce cycle time and improve productivity.

- Safe: Always ensure equipment is in good condition and follow safety rules to prevent accidents.

- Reasonable: Understand crane performance and control loads properly based on specific conditions.

Observing the “Ten No-lifts” rule

Operators must follow the “Ten No-lifts” safety rule to avoid potential hazards:

- Do not lift when signals are unclear or in violation of regulations.

- Do not lift loads exceeding rated capacity.

- Do not lift if slings are defective, inappropriate, or if loads are poorly secured.

- Do not lift loads with people or loose objects on them.

- Do not lift if brakes or other safety devices are faulty.

- Do not use a crane to process workpieces directly.

- Do not lift loads in a tilted or side-pulled manner.

- Do not lift explosive items.

- Do not pull items buried underground.

- Do not lift items with sharp edges or damage unless properly padded.

Human error is a significant risk factor in overhead crane accidents. Through systematic training, reasonable work arrangements, and strict enforcement of safety rules, the likelihood of operator mistakes can be greatly reduced. Safe crane operation depends not only on proper equipment maintenance but also on operators' skills and commitment to safety.

Conclusion

With careful planning, proper maintenance, and comprehensive training, overhead crane accidents can be effectively prevented. By understanding common causes—such as falling objects, collisions, electric shocks, mechanical failures, operator errors, and dropped materials—the industry can implement targeted safety measures. Regular equipment inspections, strict adherence to OSHA crane safety standards, and fostering a safety culture on job sites are all crucial for reducing accident risks.

Following these best practices not only enhances workplace safety but also improves operational efficiency. Well-maintained and safely operated cranes are less likely to experience costly downtime, helping businesses run more smoothly while safeguarding workers' lives.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!