Largest Overhead Crane in the World: A Marvel of Modern Engineering

Table of Contents

The world's largest overhead crane was independently developed by China First Heavy Industries (China First Heavy Machinery Group Co., Ltd.), with a lifting capacity of up to 1,300 tons. It has been recognized by the China Heavy Machinery Industry Association as the “world's largest single-hook gantry crane.” This largest overhead crane measures approximately 31.3 meters in length, 18 meters in width, and 8.9 meters in height, covering an area nearly the size of a standard basketball court, showcasing impressive structural scale and manufacturing strength.

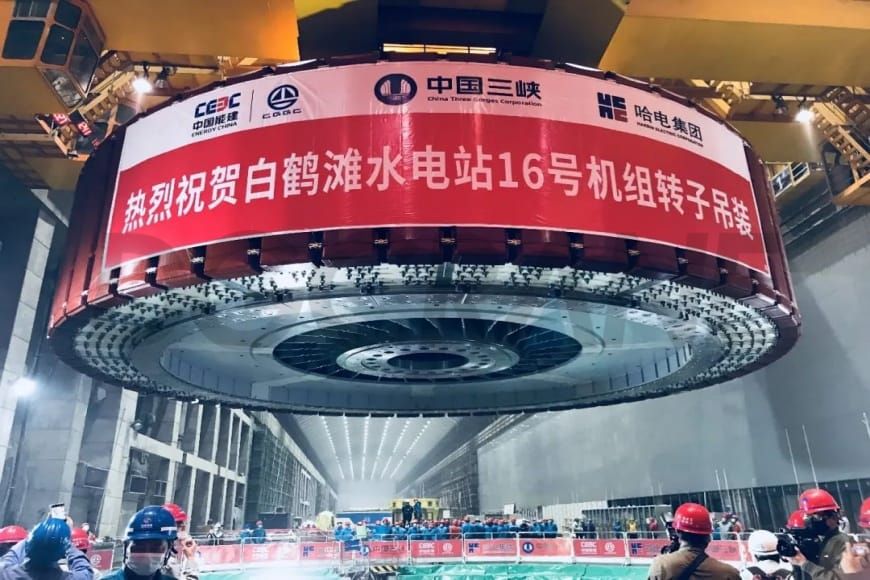

It features an industry-first new type of winding hoisting mechanism combined with an eight-point grouped drive and automatic correction system. These innovations significantly enhance lifting stability and safety while effectively reducing wire rope wear, ensuring long-term efficient operation. The crane has been deployed in major hydroelectric projects such as Baihetan and Wudongde, handling the core equipment lifting tasks with a precision level described as “lifting thousands of tons with millimeter accuracy.”

The successful application of this “steel giant” not only represents a technological breakthrough for China in heavy equipment manufacturing but also marks a significant step forward for overhead cranes worldwide toward higher-end and intelligent development.

Technical Specifications

| Feature | Specification |

| Max Lifting Capacity | 1300 tons (single point) |

| Bridge Size (L×W×H) | 31.3 m × 18 m × 8.9 m |

| Control System | Intelligent digital control with real-time monitoring |

| Rope Mechanism | Multi-drum, precision-wound steel cable system |

| Drive System | 8-point synchronized drive with auto-alignment |

| Crane Type | Overhead Crane |

| Precision | ±1 mm positioning accuracy |

Application Projects

Project: Baihetan Hydropower Station Construction

The 36 hydro-turbine units installed at Baihetan feature the world's largest single-unit capacity, and for the first time globally, the turbine runner was designed and manufactured with zero counterweight. Once delivered, this runner will be installed in the underground powerhouse of Baihetan for Unit 15. In total, 16 million-kilowatt-class hydro-turbine units—the largest in the world—will be installed in the Baihetan underground powerhouse.

Apart from the runner, the generator rotor is another key component. During operation, the rotor spins at high speed inside the stator to generate stable, clean electricity. The generator rotor for Unit 1 weighs an astonishing 2,100 tons. No single piece of equipment on-site could lift it independently; instead, two 1,300 ton largest overhead cranes had to work in tandem to complete the hoisting task.

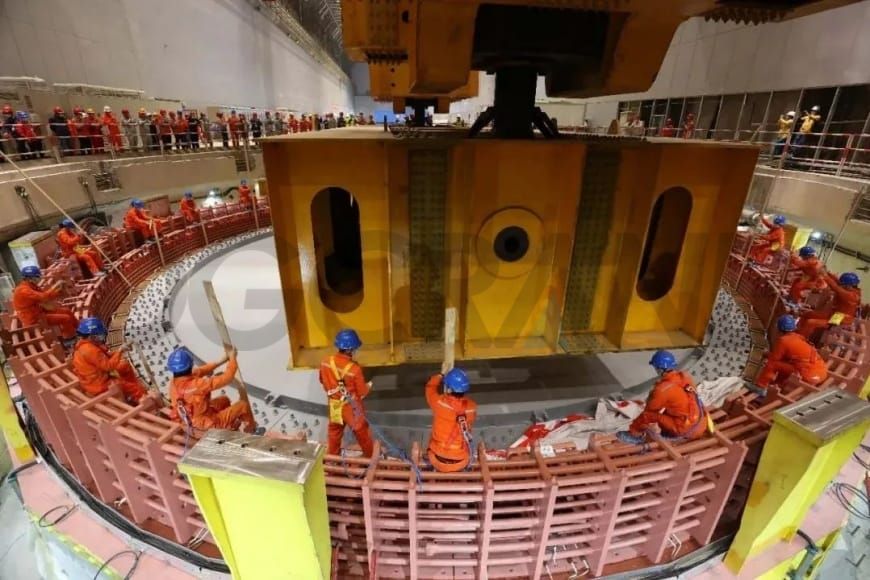

During the lift, the rotor was steadily raised to a height of 5.8 meters. The two largest overhead cranes then moved forward slowly at a speed of 7 meters per minute to complete a 335-meter straight-line hoist. Maintaining a stable and uniform speed with precise angle control was critical throughout the process. Crane operator Tian Demei had to ensure the operating error was within 1 millimeter; otherwise, rotor sway or collision with the stator could occur, resulting in serious consequences.

After continuous adjustments by the workers to align the rotor's center position, the installation was successfully completed in one and a half hours, marking the precise and successful placement of the generator rotor for Baihetan Unit 1.

Project: Construction of Wudongde Hydropower Station

The generator rotor of the Wudongde left-bank power station mainly consists of the rotor hub, rotor arms, magnetic yoke, and magnetic poles. It has an outer diameter of 17.49 meters, a height of 4.045 meters, and a total weight of approximately 1,910 tons. The rotor was hoisted using a dual-crane lifting method with two 1,300 ton largest overhead cranes operating in tandem.

Before hoisting, the rotor was successfully assembled through a series of high-precision processes, including support frame assembly and welding, rib machining, yoke stacking, rotor shrink fitting, pole mounting, and pressure testing. The high-quality assembly work received unanimous praise from all involved parties.

During the assembly process, the mechanical and electrical builders from Gezhouba embodied the spirit of craftsmanship and pursuit of excellence. Through innovative installation techniques and the extensive application of new technologies and materials, all technical indicators of the rotor assembly exceeded standard requirements. After the hot shrink-fitting of the magnetic yoke, the cylindricity was controlled to 0.41 mm; after pole mounting, the overall roundness of the rotor reached 0.38 mm; and the radial and circumferential perpendicularities of the positioning ribs were maintained at 0.17 mm and 0.15 mm, respectively.

Beyond Size: DGCRANE Builds the Right Crane for Your Needs.

The world's largest overhead crane isn't for everyone — what truly matters is having a lifting solution that fits your operation: safe, efficient, and economical.

That's where DGCRANE comes in.

Who We Are

DGCRANE is a trusted overhead crane manufacturer and exporter, serving industrial clients in 120+ countries. From light-duty workshop cranes to heavy-duty gantry and bridge cranes, we deliver custom-engineered lifting equipment that meets international standards at competitive prices.

What We Offer

- Overhead cranes (single & double girder)

- Gantry cranes, jib cranes, hoists

- CE/ISO-certified systems

- Expert design & quick overseas delivery

Serving Industries Like:

- Steel & metallurgy

- Machinery manufacturing

- Warehousing & logistics

- Power & renewable energy

- Construction & shipyards

Get a Free Custom Quote Today

Let our engineers recommend the best solution for your lifting needs — no matter your location.

Global Success Case from DGCRANE

With customers in over 120 countries, DGCRANE has delivered thousands of customized overhead crane solutions to industries around the world. From steel plants in South Asia to warehouses in South America, to manufacturing workshops in Africa and the Middle East, our cranes are trusted for their reliability, safety, and cost-effectiveness.

Shandong Ductile Iron Pipe Co., Ltd. Environmental Relocation Project

This project is the environmental relocation initiative of Shandong Ductile Iron Pipe Co., Ltd. Phase I mainly includes the construction of two 350m³ blast furnaces, one 120m² sintering machine, and a supporting facility for an annual production capacity of 500,000 tons of ductile iron pipes.

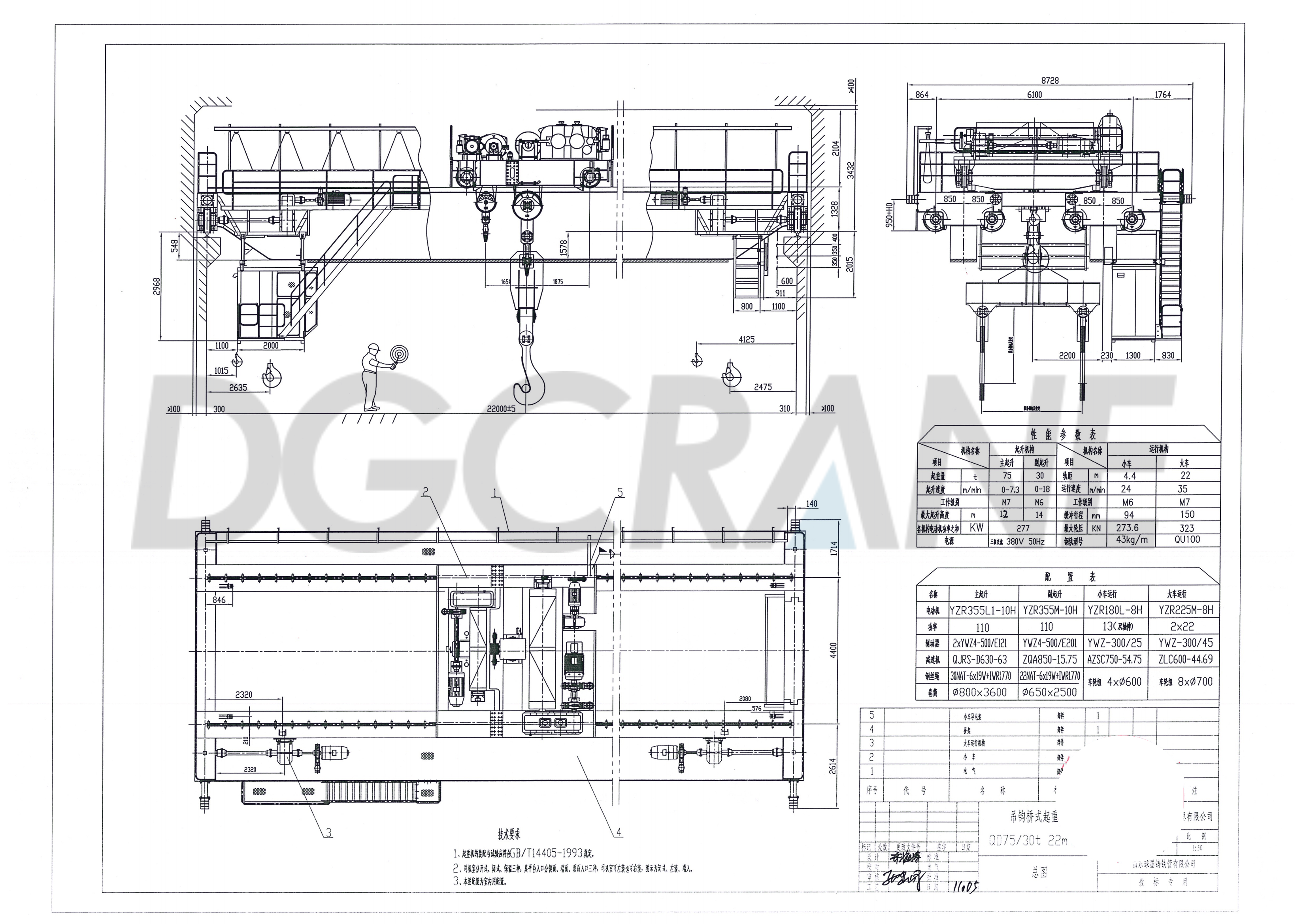

A 75/30T overhead crane is used for ladle maintenance (removing the 65-ton hot metal ladle) and for tilting the ladle during pig iron casting operations.

Crane Specifications:

- Lifting Capacity: 75/30 tons

- Working Duty: A6

- Span: 22 m

- Lifting Height: 12/14 m

- Lifting Speed: 7.3 / 18 m/min

- Ambient Temperature: -18°C to +80°C

- Control Mode: Cabin control + Ground remote control

- Power Supply: AC 380V / 50Hz

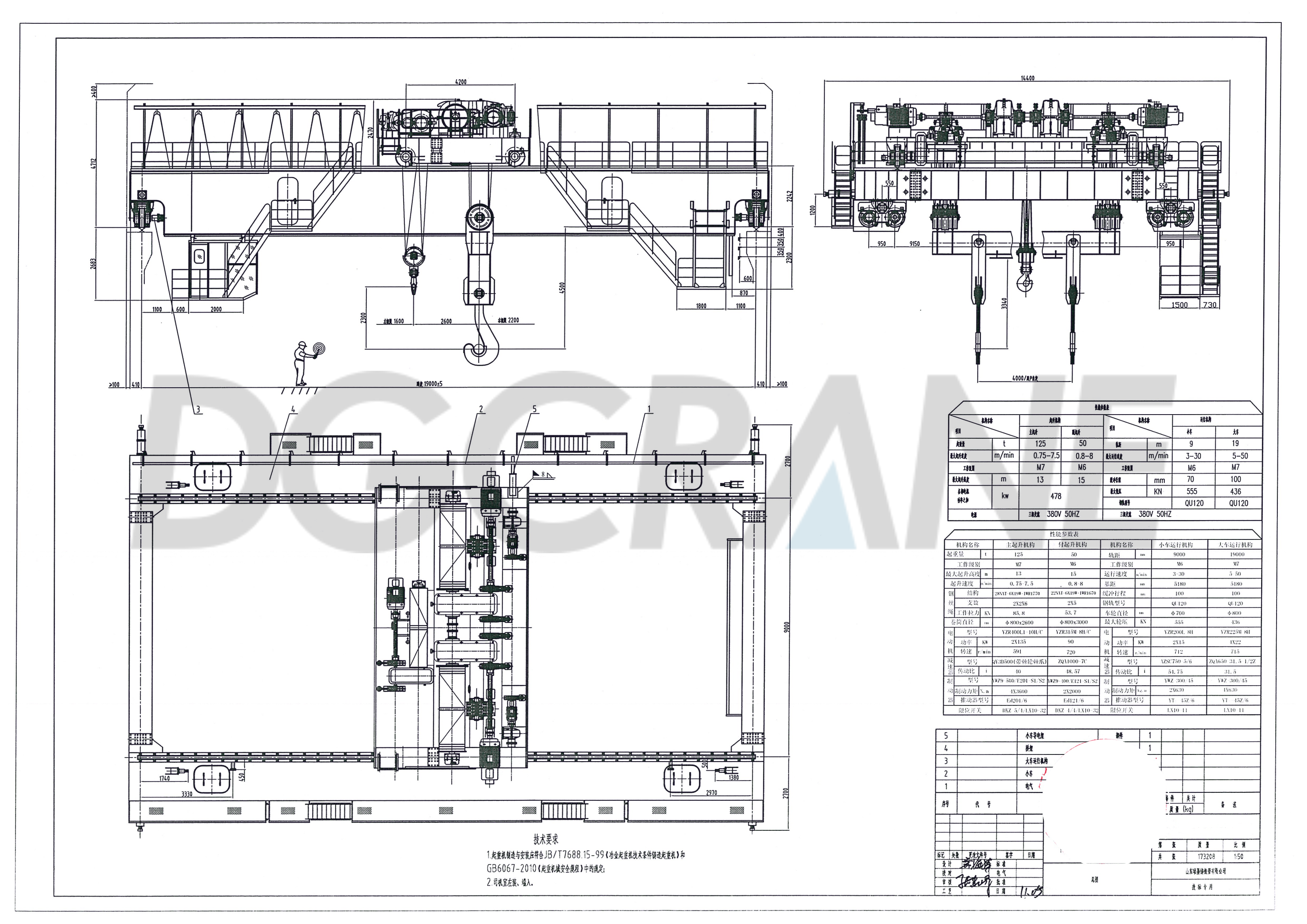

The 125/50T casting crane is used for pouring molten iron from a 65-ton hot metal ladle. The main hook is designed to meet the lifting requirements of the ladle. All crane motions—including main hoisting, auxiliary hoisting, long travel, and cross travel—adopt stator voltage regulation and speed control to ensure precise handling during the pouring process.

The crane is equipped with a molten iron weighing system, featuring a clearly visible display that can be easily read from the ground, as well as a signal transmission interface for data communication.

Crane Specifications:

- Lifting Capacity: 125/50 tons

- Working Duty: A7

- Span: 19 meters

- Lifting Height: 13 m (Main Hook) / 15 m (Auxiliary Hook)

- Trolley Traveling Speed: 30 m/min

- Control Mode: Cabin control + Ground remote control

- Power Supply: AC 380V / 50Hz

Malaysia-China Kuantan Industrial Park 3.5 Million Tons Steel Energy-Saving and Environmental Protection Project

Crane specification

- Capacity: 80/20 ton

- Lifting height: 20/22m

- Work duty: A6-A7

- Lifting speed: 0.7-7/1.2-12 m/min

- Lifting mechanism: electric wire rope hoist

- Control mode: control pendant

- Power source: 380V/50Hz/3PH

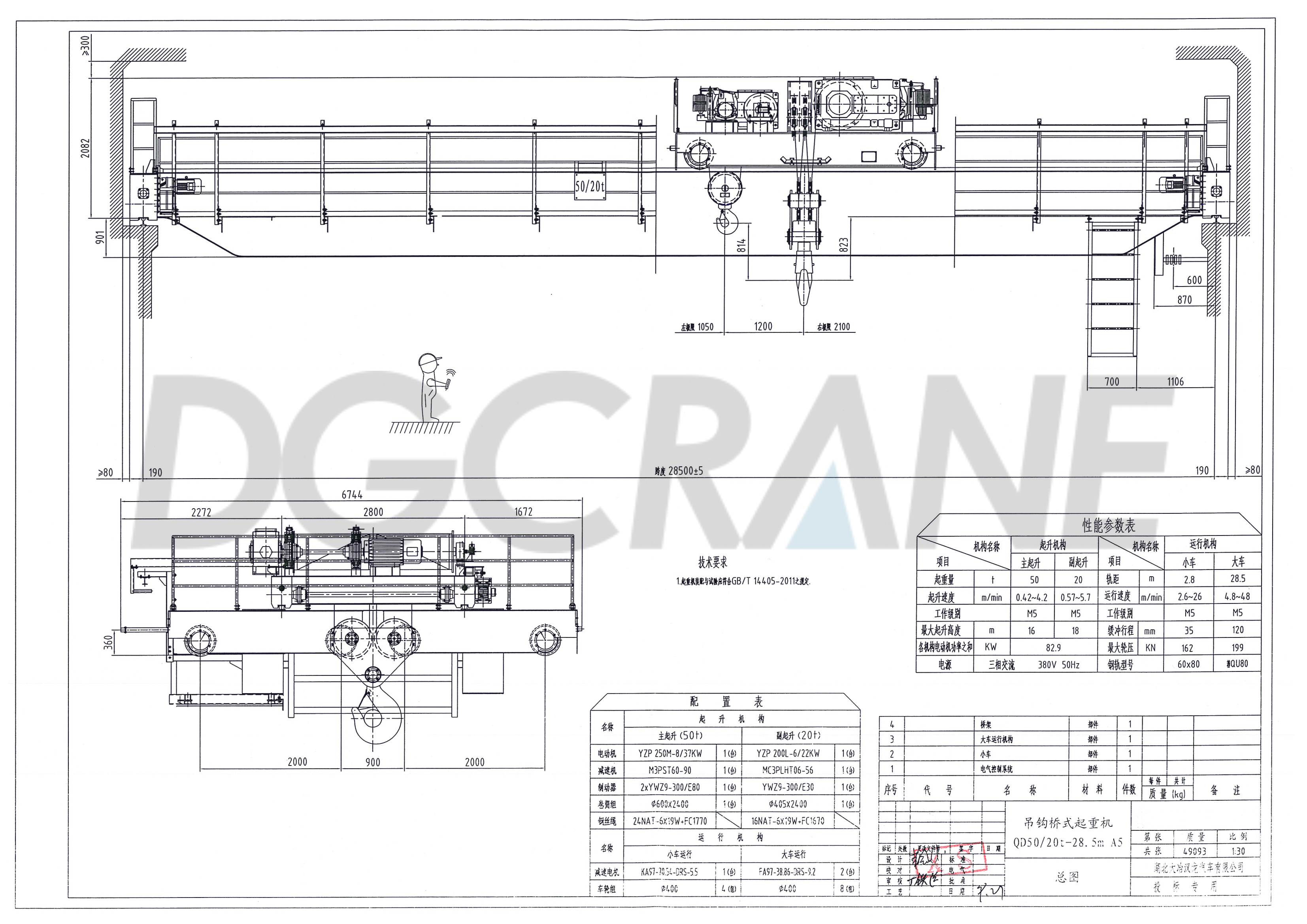

Hubei Daye Hanlong Automobile Co., Ltd. Crane Equipment Project

Crane Specifications:

- Lifting Capacity: 50T / 20T

- Span: 28.5 meters

- Lifting Height: 16 m (Main Hook) / 18 m (Auxiliary Hook)

- Working Duty: A5

- Control Mode: Pendant control + Wireless remote control

- Power Supply: 380V/50Hz/3PH

Conclusion

The creation of the world's largest overhead cranes is not just a demonstration of mechanical scale, but a reflection of human ingenuity, engineering precision, and industrial ambition.

As demands for heavier and more complex lifting continue to grow—especially in sectors like hydropower, shipbuilding, and infrastructure—the design of ultra-large bridge cranes will remain a key benchmark in industrial capability.

While such giants are rare, they push the boundaries of what’s possible, inspire innovation, and pave the way for more efficient, scalable lifting solutions across all levels of industry.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!