-

INDUSTRIES

-

Precast Concrete Plant

-

Steel Industry

-

Paper Industry

-

Waste to Energy and Biomass Industry

-

Power Industry

-

Overhead Cranes for Automotive Production: Smart Solutions for Enhanced Efficiency

-

Port Machines Industry

-

Manufacturing Industry

-

Different Types of Container Cranes, Shipyard Cranes, Cargo Cranes Used in Port, Harbor and Quay

-

Overhead Cranes for Timber Lifting: Efficient and Safe Wood Handling

-

Overhead Cranes for the Aviation Industry: Streamlining Aircraft Assembly, Maintenance, and Repair

-

Overhead Cranes for Food and Beverages: Ideal for improving productivity and food safety

-

Overhead Cranes for Aerospace Industry: Key Role in Efficient Rocket Manufacturing and Launch

-

-

EQUIPMENT

-

Overhead Cranes

-

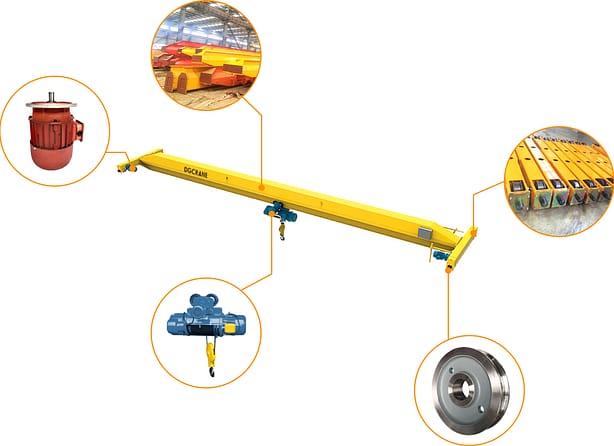

Single Girder Overhead Crane

-

Double Girder Overhead Crane

-

Underslung Cranes

-

Workstation Overhead Cranes

-

Low Headroom Overhead Cranes

-

Grab Bucket Overhead Crane

-

Electromagnetic Overhead Cranes with Lifting Magnet

-

Electromagnetic Overhead Cranes with Magnet Beam

-

Manual Overhead Cranes

-

Double Trolley Overhead Cranes

-

LDP Single Girder Overhead Cranes

-

- Eot Cranes

- Gantry Cranes

- Jib Cranes

- FEM Standard Crane & Hoist

- Hoist & Winch Trolley

- Light Cranes

- Explosion Proof Cranes and Hoists

-

Special Cranes

-

35-65t Clamp Overhead Crane

-

Boat Hoists

-

Boat Jib Crane

-

Yacht Davit Crane

-

Rail Mounted Container Gantry Crane

-

Cleanroom Overhead Cranes

-

YZ Ladle Handling Cranes

-

LDY Metallurgical Single Girder Crane

-

Charging Cranes for Steel Production

-

Insulated Overhead Cranes

-

Gantry Crane for Subway and Metro Construction

-

Forging Crane

-

Quenching Overhead Crane

-

Baking Multifunctional Crane

-

- Port Cranes

- Electric Transfer Carts

-

Overhead Cranes

-

CRANE PARTS

- Crane Wheel Range

- Crane Spreader

- Crane Drives

-

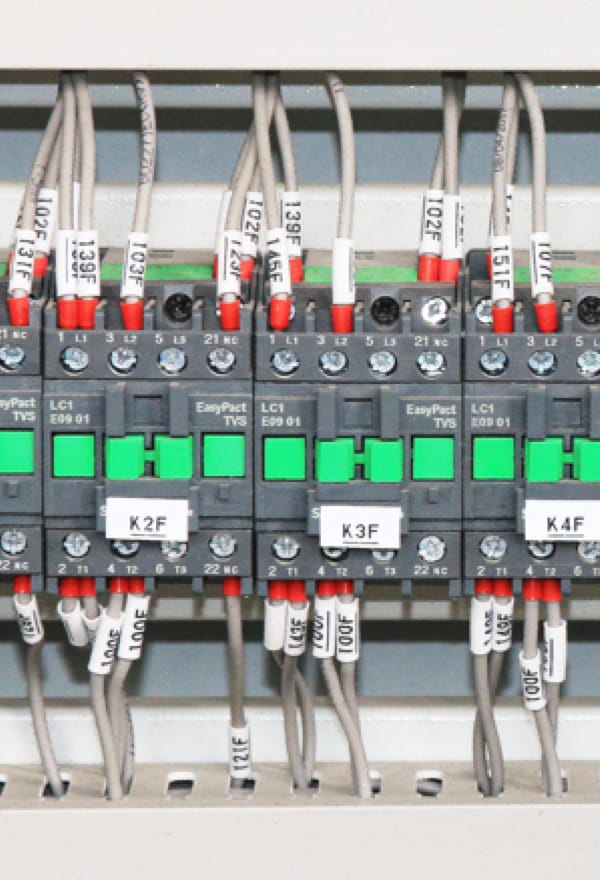

Crane Electrical Equipment

-

Overload Limiter

-

Crane Cabin

-

Crane Power Supply System

-

Explosion Proof Crane Radio Remote Controls

-

Joystick Type Crane Radio Remote Controls

-

Pushbutton Type Crane Wireless Remote Controls

-

Single-pole Insulated Conductor Rails

-

Enclosed Conductor Rails

-

Seamless Conductor Rails

-

Copperhead Conductor Rails

-

Overhead Crane Cables

-

- Other Cranes Parts

\

- ABOUT US

- CONTACT US