How Can Estimators Material Handling Costs For Manufacturer

How Can Estimators Material Handling Costs For Manufacturer

One way to reduce waste for lean manufacturing is to minimize the materials handling and parts. Efficiencies can equal cost savings, which can lead-to higher profits, or better yet, a strategically powerful way to be more competitive!

When manufacturers lack efficient material and part handling processes, accountants increase overhead rates to account for labor expense. Overhead rates are applied to the complete job instead of charging costs individually, for example, rent, lighting, insurance, etc.

When a "fixed material handling" percentage is added to overhead, some parts could have excess cost...overpricing estim ates. On the other hand, when a job has inefficient handling steps, the job can be estimated with an unrecognized lower cost -- lowering profits.

"Lean manufacturing is a variation on the theme of efficiency based on optimizing flow; it is a present-day instance of the recurring theme in human history toward increasing efficiency, decreasing waste, and using empirical methods to decide what matters, rather than uncritically accepting pre-existing ideas." -- as found on Wikipedia

"Padding overhead" can be reasonable when estimators don't have a consistent method to apply handling standards to their estimates, as well as considering that material handlers have lower wages. However, more companies operate with very tight profit margins and constantly strive to be a lean manufacturer. While this is clearly less of an issue for prototype shops, material handling costs can escalate for medium-high production-run companies, like for the automotive industry.

Estimators who communicate with their production staff, specifically industrial engineers, can identify time-consumers and have the ability to work-in alternative processes and implement timesaving standards. When estimators use systems that include standards, their accounting department can reduce overhead rates in efforts to more consistently attain real costs for the parts they manufactured, quote, or procure.

"In my many years of on-site trainings, I've walked through a variety of impressive shops who are doing things right. I've also witnessed situations where excessive time is spent configuring and moving material and parts which all increase the cost for those manufactured parts. It's important not to be penny-wise and pound-foolish when a little thought can save a ton of time. While it goes without saying... Time is money!"-- Aaron Martin, Estimating Manager, MTI Systems, Inc.

How can estimators accurately account for and consistently apply these standards?

Cost estimating software, for instance, Costimator is shipped with thousands of preconfigured standards. As with many of its other features, it provides the ease and flexibility to add and modify existing data and manufacturing details. Estimators can then configure the system -- based on new processes and unique or proprietary manufacturing environments for their specific company needs. When estimators use software they can easily match the real cost of the parts they estimate, increasing their quoting performance and sales results -- against that of their competition.

More "material handling" cost reduction ideas:

? Communicate with your production staff to identify time-consuming steps and convert them to time-savings.

? Use software to breakout material handling and reduce overhead rates.

? Receive materials at their final destination - shuffling materials and parts adds cost..."not value."

? During production, could it be more cost effective to instead to move a machine to the material?

? Ensure each step during production occurs at the right time. (I.E. Inspection needs to occur before packaging.)

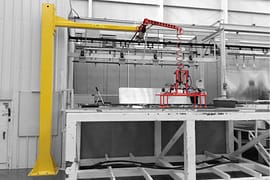

? Invest in timesaving material handling tools, like customized baskets, conveyors, mezzanines, racks, cranes, and more.

What material handling ideas, tools and products can you recommend that can save time for manufacturers?